Silver paste, method for producing same, and method for producing bonded body

A silver paste, volume technology, applied in the direction of metal/alloy conductor, cable/conductor manufacturing, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

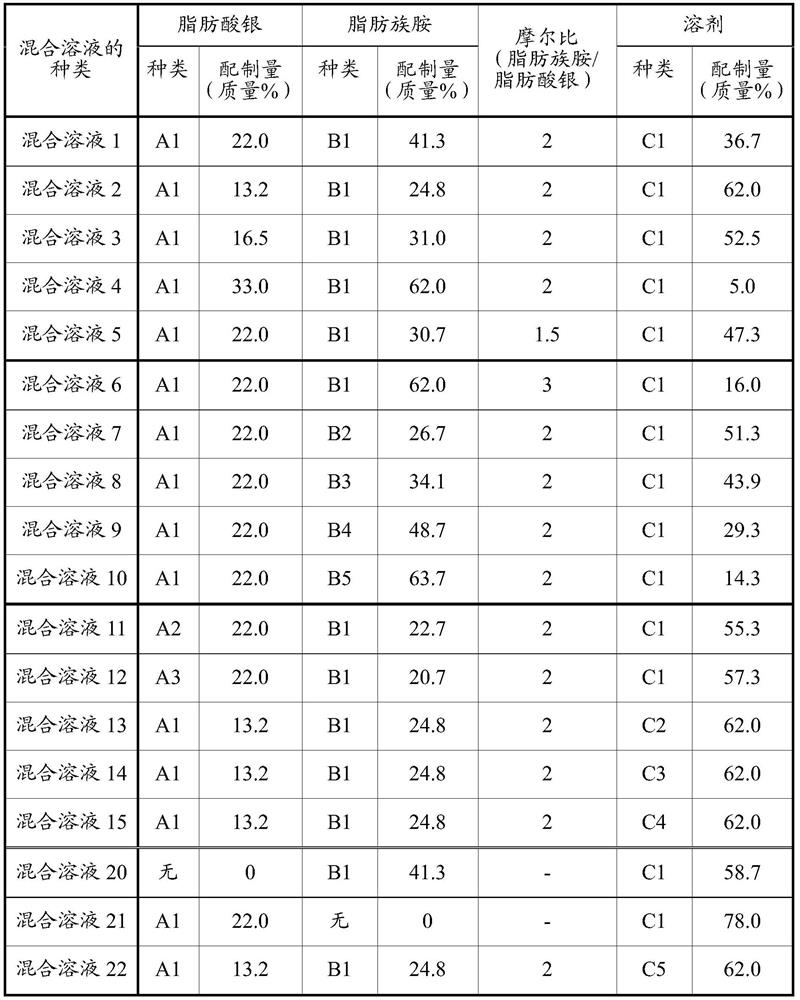

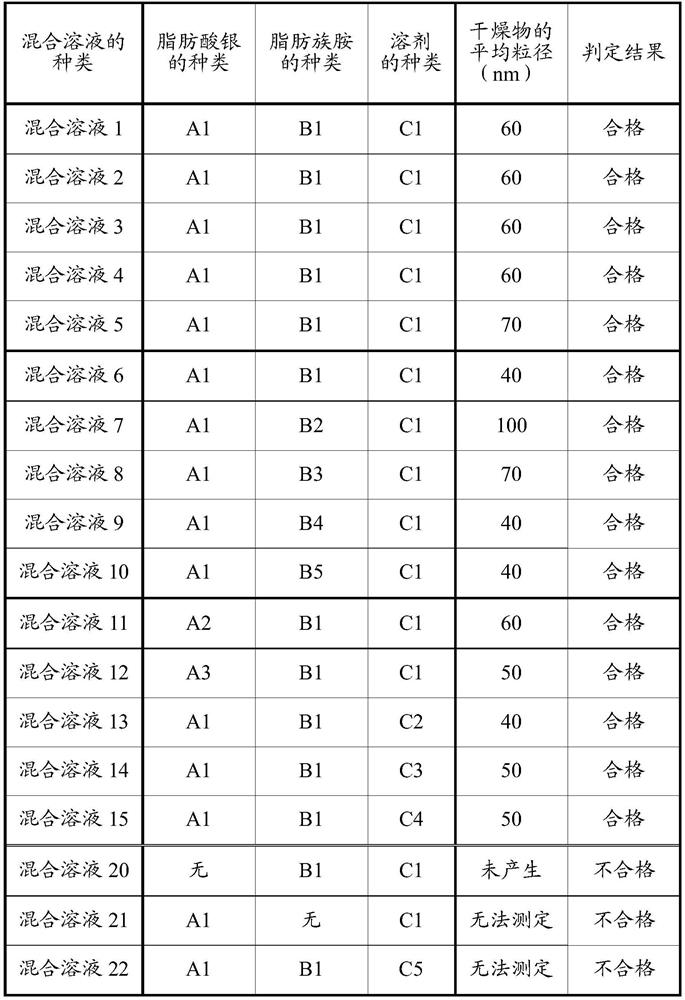

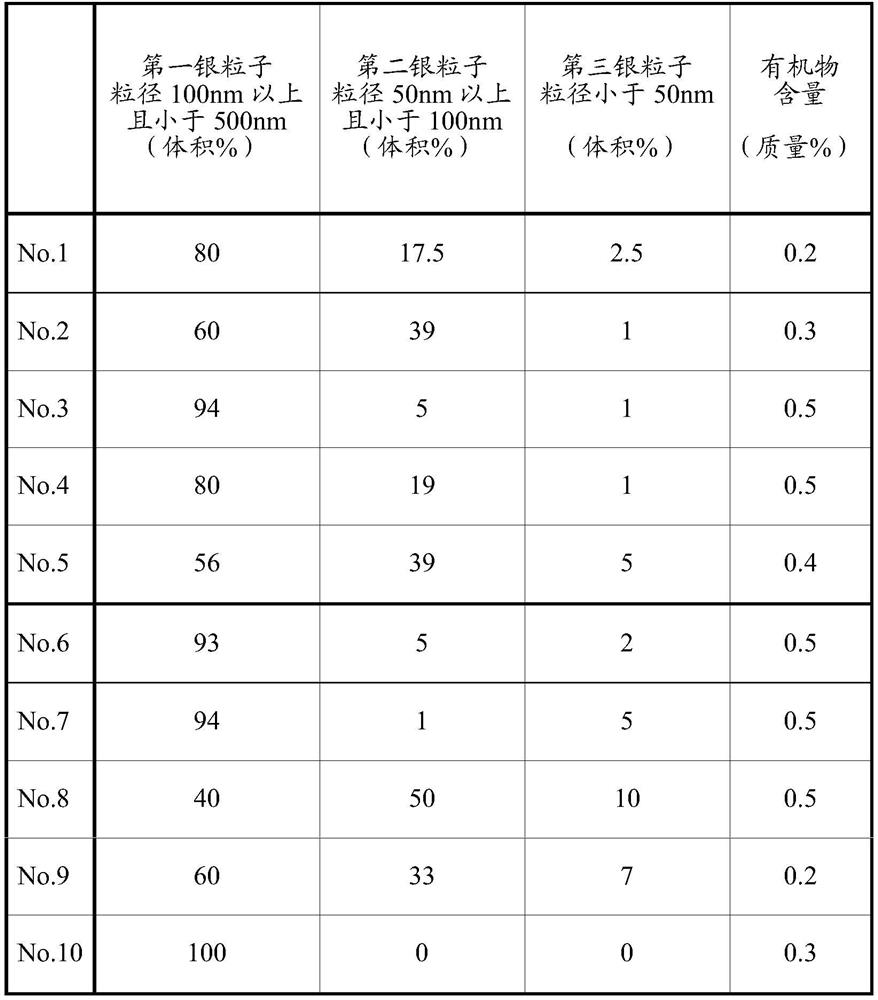

[0104] In order to make the silver paste 100 mass %, mixed solution 1 (24.00 mass %), No. 1 silver powder (75.00 mass %), and 1,2,4-butanetriol (D1) which is a high dielectric constant alcohol (1.00 mass %) After mixing, it stirred with a planetary mixer, and further kneaded with a three-roll mill. Thus, a silver paste was obtained. This silver paste was taken as Example 1.

Embodiment 2~21 and comparative example 1~10

[0106] Each mixed solution of 31 kinds of silver pastes of Examples 2 to 21 and Comparative Examples 1 to 10 was prepared using the fatty acid silver, aliphatic amine and solvent shown in Table 1 and Table 2, and was shown in Table 4 and Table 5. The proportion of silver powder, mixed solution and high dielectric constant alcohol were prepared respectively. A silver paste was prepared in the same manner as in Example 1, except for the preparation of the silver powder, the mixed solution, and the high-dielectric-constant alcohol shown in Tables 4 and 5. However, Comparative Examples 2 and 4 did not become pastes for the reasons described later. In Examples 5, 6, 11, 12, 18 and 19, two high dielectric constant alcohols were used.

[0107] In the column of the type of mixed solutions in Tables 4 and 5, the mixed solutions used in Examples 1 to 21 and Comparative Examples 1 to 10 were selected from "mixed solutions 1 to 15" or "mixed solutions 20 to 22". any representation. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap