Storage film automatic edge pressing equipment for forage grass ensiling

An automatic and forage technology, applied in applications, feed, food processing, etc., can solve the problems of wasting film storage materials, long wrapping time, and long time spent, so as to prolong the use time, improve fermentation efficiency, and reduce impact force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0045] like Figure 1-13 As shown, this application provides:

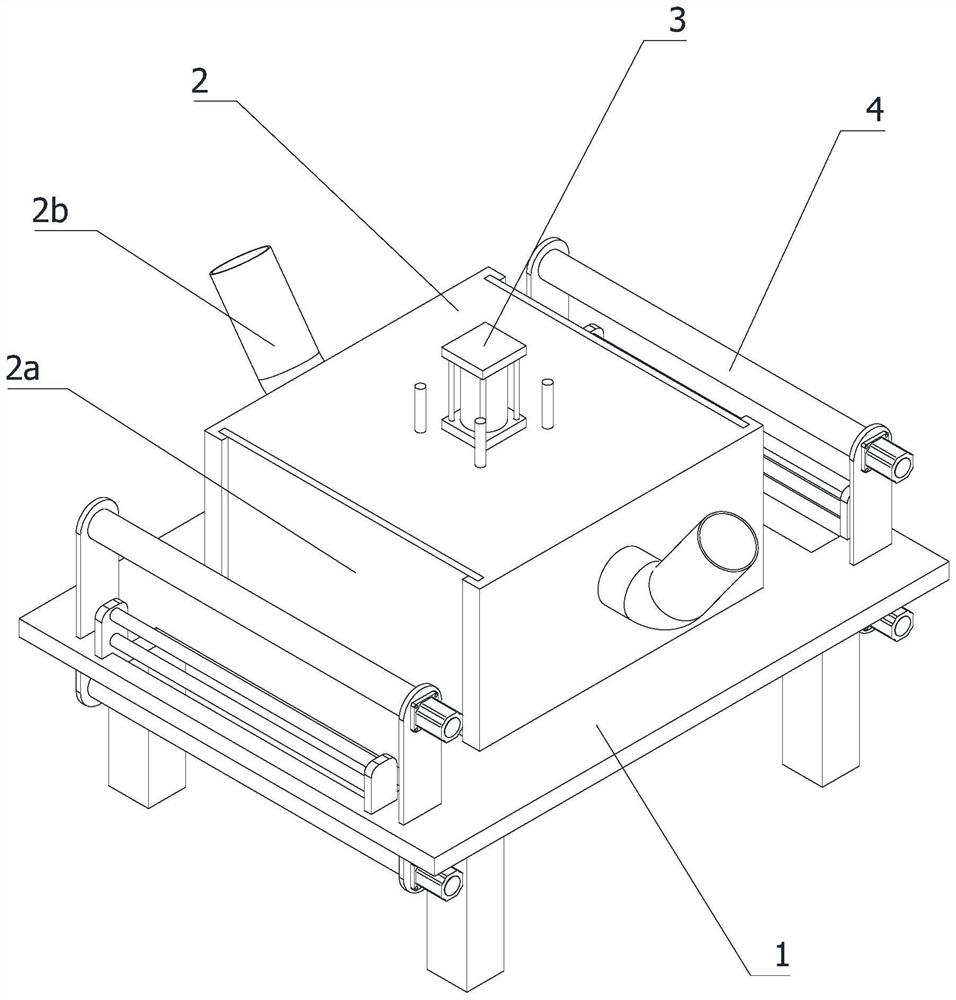

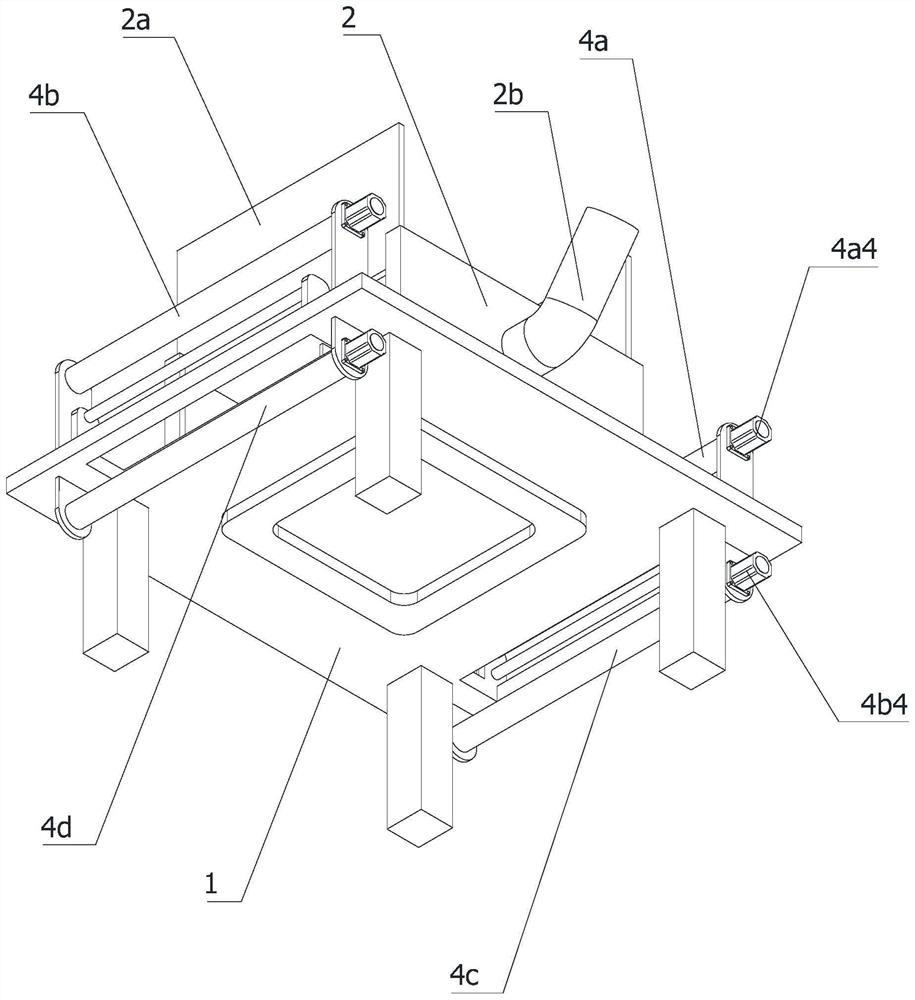

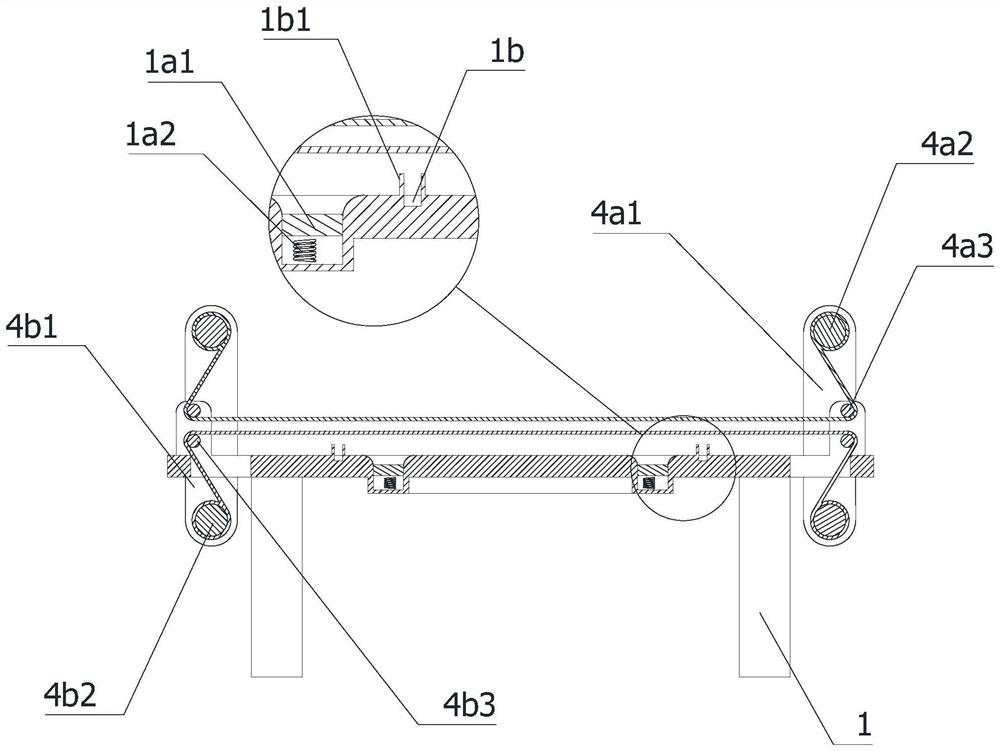

[0046] A film-storing automatic edge-pressing equipment for forage silage, comprising a workbench 1, a processing box 2, a side-pressing mechanism 3 and a film-storage feeding mechanism 4 are arranged on the workbench 1, and the processing box 2 is a rectangular box structure. , the two sides of the processing box 2 are provided with sliding doors 2a that are slidably matched with them, and the other two sides of the processing box 2 are provided with air extraction pipes 2b. Assembly 4b, lower discharge assembly 4c and lower discharge assembly 4d, the upper discharge assembly 4a and the lower discharge assembly 4c are located on the side of one of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com