Cartilage tissue engineering compound and application thereof

A cartilage tissue and composite technology, applied in the field of biomedical tissue engineering, can solve the problems of limited proliferation of articular cartilage cells, long waiting time for patients, and low strength of cell-material composites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

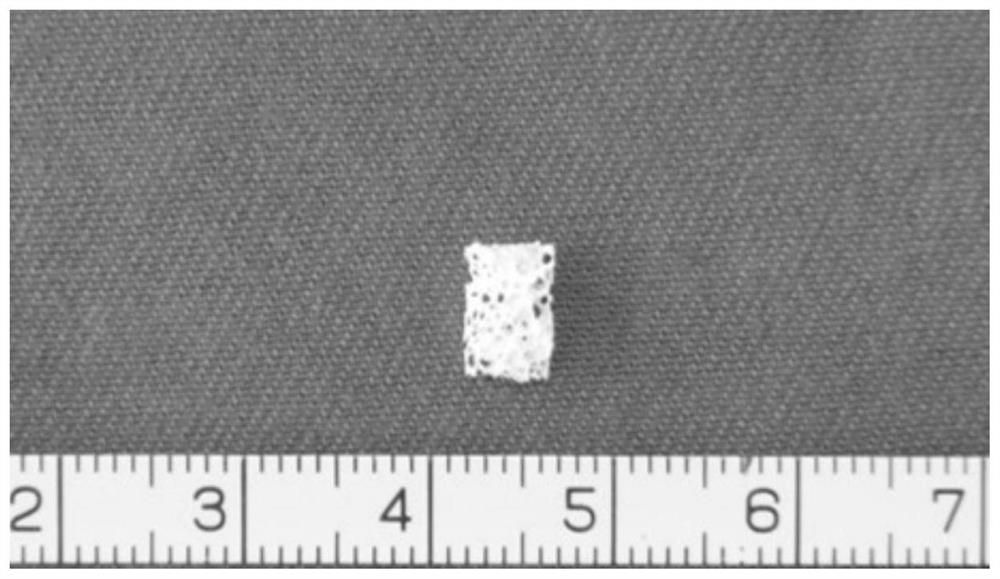

[0142] Preparation of cartilage gel-demineralized bone complex

[0143] In this example, a cartilage gel-framework complex was prepared. The specific operation method is as follows:

[0144] (1) Take the subject's autologous ear cartilage tissue, aseptically cut 2.5 × 2.5 cm 2 cartilage tissue, use sterile instruments to peel off the mucosa and fibrous tissue on the cartilage surface;

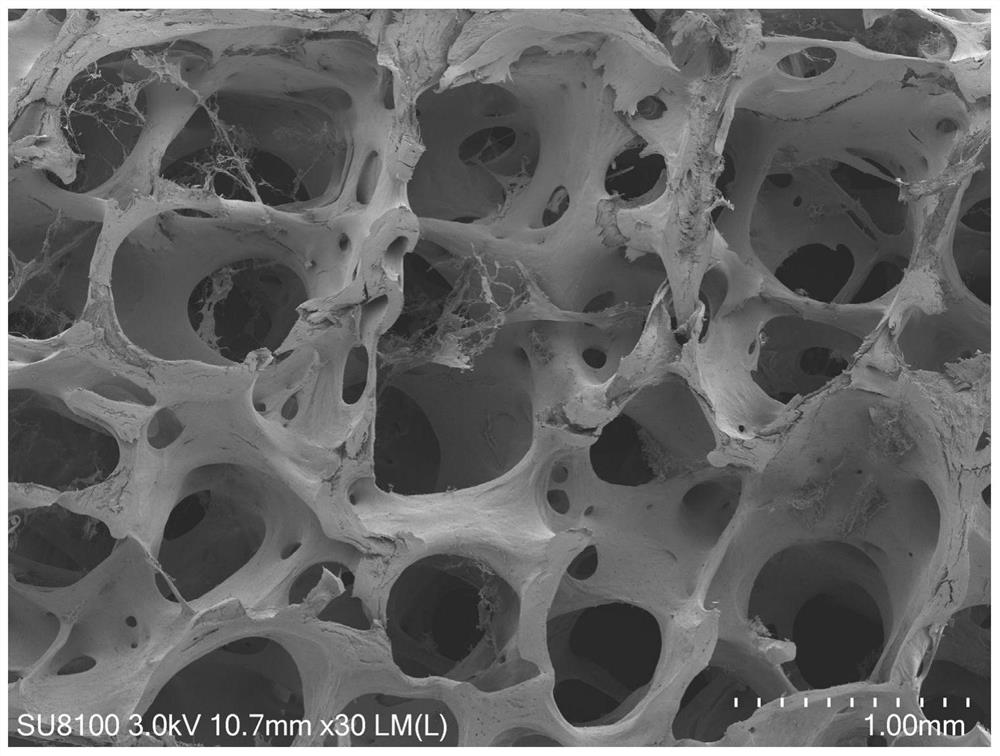

[0145] (2) Cut the cartilage tissue into 1.5×1.5mm 2 Large and small cartilage fragments; the preparation concentration is 0.15% collagenase; the cartilage fragments are added to the prepared collagenase to digest for 8 hours;

[0146] (3) After 8 hours, the collagenase solution was filtered and centrifuged to obtain ear chondrocytes, and primary and subculture were carried out using high glucose DMEM medium containing 10% FBS;

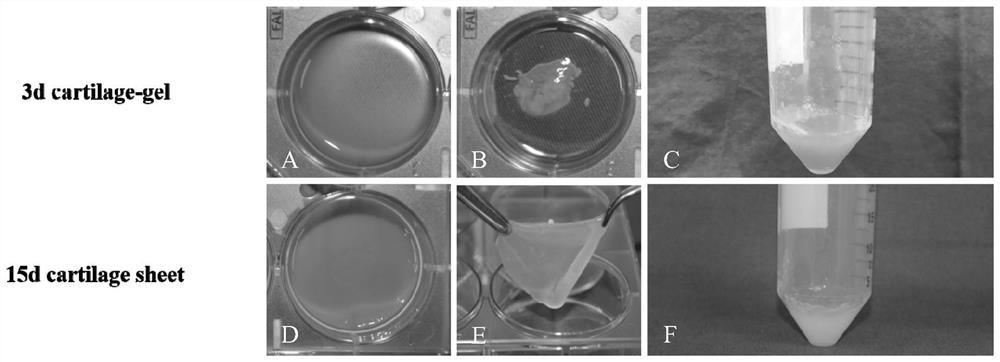

[0147] (4) After the expansion, collect the cells and resuspend them according to 8×10 6 / 10ml to 30×10 6 Cells / 10ml / well were seeded in six-well plates and cult...

Embodiment 2

[0153] Preparation of Perichondrial Sheet Particles-Demineralized Bone Complex

[0154] In this example, perichondrial sheet particle-framework complexes were prepared. The specific operation method is as follows:

[0155] (1) Aseptically cut 2.5×2.5cm 2 ear cartilage tissue; use sterile instruments to peel off the mucosa and fibrous tissue on the cartilage surface;

[0156] (2) Cut the cartilage tissue into 1.5×1.5mm 2 Large and small cartilage fragments; the preparation concentration is 0.15% collagenase; the cartilage fragments are added to the prepared collagenase to digest for 8 hours;

[0157] (3) After 8 hours, the collagenase solution was filtered and centrifuged to obtain ear chondrocytes, and primary and subculture were carried out;

[0158] (4) After the expansion, collect the cells and resuspend them according to 8×10 6 / 10ml to 30×10 6 Cells / 10ml / well were seeded in six-well plates and cultured in gelatinization medium (DMEM medium containing 4-5wt% glucose,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com