Method and system for pre-atomizing catalytic feed oil

A technology of feed oil and feed port, applied in chemical instruments and methods, catalytic cracking, feed devices, etc., can solve the problem of poor atomization effect of catalytic feed oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

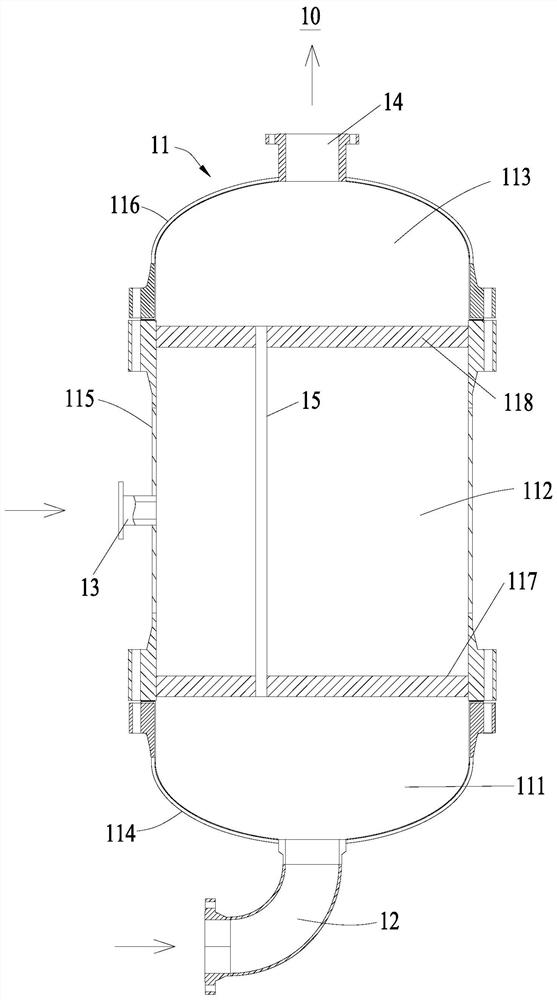

[0096] In the present embodiment, the pre-atomization of the catalytic feed oil is carried out according to the following steps:

[0097] (1) The atomized gas is introduced into the middle cavity of the micro-interface treatment tank through the atomized gas feed port, and the atomized gas enters the micro-interface catheter through the air hole on the pipe wall of the micro-interface catheter for dispersion. , to obtain microbubbles, and the dispersion conditions include: the temperature is 250 ° C, the pressure is 1.0 MPa, the feed flow of the atomizing gas is 130 kg / h; the atomizing gas is superheated steam;

[0098] (2) The catalytic feed oil is introduced into the bottom cavity of the micro-interface treatment tank through the catalytic oil feed port, and the catalytic feed oil enters the micro-interface conduit through the bottom inlet of the micro-interface conduit, and is combined with the micro-interface conduit. The microbubbles are mixed to obtain gas-liquid emulsio...

Embodiment 2

[0102] This example is carried out by a method similar to that of Example 1, the difference is: in step (1), the dispersion conditions include: the temperature is 250°C, the pressure is 1.0MPa, the feed flow rate of the atomizing gas is is 390kg / h; the atomized gas is superheated steam.

[0103] The density of pre-atomized heavy exhaust liquid emulsion phase oil is 550kg / m 3 , the average diameter of the oil droplets is 430nm; the heavy exhaust liquid emulsion phase oil is introduced into the atomizing nozzle for atomization, and introduced into the catalytic cracking reactor for catalytic cracking reaction, the results show that: the catalytic feed oil is directly Introduced into the atomizing nozzle for atomization, and introduced into the catalytic cracking reactor to carry out catalytic cracking reaction (without pre-atomization by the device of the present invention) as a benchmark comparison, the yield of light oil + liquefied gas increased by 1.87wt%, The coke yield de...

Embodiment 3

[0105] This example is carried out by a method similar to that of Example 2, the difference is: in step (2), the mixing conditions include: the temperature is 200° C., the pressure is 0.7MPa, the feed of the catalytic feed oil is The flow rate is 100t / h.

[0106] The density of pre-atomized heavy exhaust liquid emulsion phase oil is 500kg / m 3 , the average diameter of the oil droplets is 670nm; the heavy exhaust liquid emulsion phase oil is introduced into the atomizing nozzle for atomization, and introduced into the catalytic cracking reactor for catalytic cracking reaction, the results show that: the catalytic feed oil is directly Introduced into the atomizing nozzle for atomization, and introduced into the catalytic cracking reactor for catalytic cracking reaction (without pre-atomization by the device of the present invention) The reaction results were compared as a benchmark, the yield of light oil + liquefied gas increased by 1.35wt%, The coke yield decreased by 0.64 wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com