Steel frame float type offshore photovoltaic platform

A floating platform and buoy-type technology, applied in the field of photovoltaic power generation, can solve problems such as being unsuitable for marine environment and unable to meet the intensity of offshore wind and waves, and achieve the effects of increasing additional hydrodynamic quality, improving motion performance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

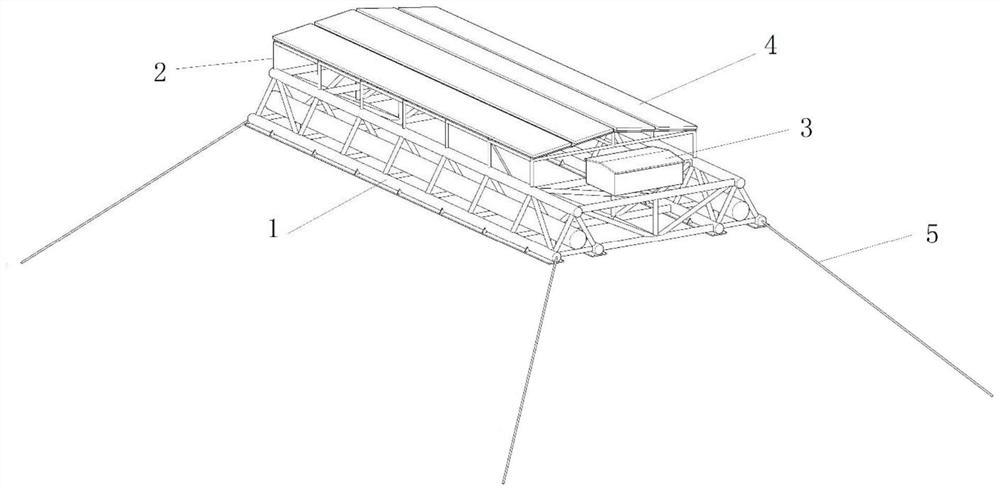

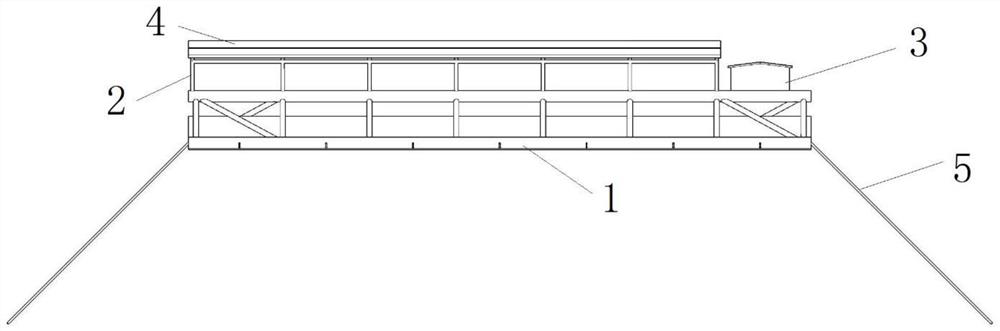

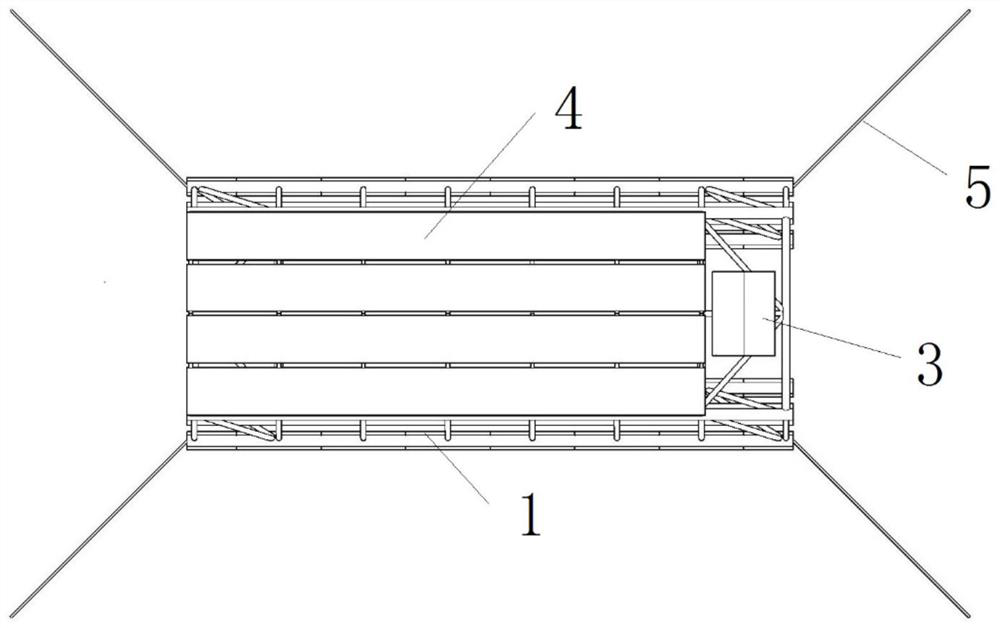

[0032] refer to Figure 1 to Figure 4 , a steel-frame pontoon-type offshore photovoltaic platform, comprising a steel-frame floating platform 1 , a photovoltaic support 2 , a photovoltaic panel 4 , a photovoltaic inverter 3 and several anchor chains 5 . The power generated by the photovoltaic panels 4 is converted into alternating current by the photovoltaic inverter 3 to convert the direct current generated by the photovoltaic modules into alternating current, and then sent to the onshore substation through the submarine cable after confluence.

[0033] The photovoltaic support 2 is fixed directly above the steel-frame floating platform 1 by welding, the photovoltaic inverter 3 is installed on the top of the steel-frame floating platform 1, the photovoltaic panel 4 is installed on the top of the photovoltaic support 2, and the steel-frame floating platform 1 and 4 The corners are respectively connected with one end of the four anchor chains 5, and the other ends of the anchor...

Embodiment 2

[0046] The steel-frame pontoon-type offshore platform can also be expanded by arranging three or more triangular lattice-type steel frames, and installing the corresponding square-type lattice-type steel frames to form a larger-sized steel-frame pontoon-type offshore photovoltaic platform.

[0047] refer to Figure 7 , a steel-frame pontoon-type offshore photovoltaic platform, comprising two steel-frame floating platforms 1 , two photovoltaic supports 2 , photovoltaic panels 4 , two photovoltaic inverters 3 and four anchor chains 5 .

[0048] Two steel-frame floating platforms 1 are arranged side by side and are welded together. The triangular lattice steel frame 110 in the middle of the two steel-frame floating platforms 1 is shared, and two photovoltaics are welded on the two steel-frame floating platforms 1 respectively. Support 2, one of the square lattice steel frames 120 on both sides is reserved as an operation and maintenance channel, and a photovoltaic inverter 3 is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com