Heating and cooling control device and method for aircraft aerodynamic thermal environment simulation test

An environment simulation test and control device technology, applied in temperature control, aircraft component testing, non-electric variable control, etc., can solve the problem that the natural cooling rate is not enough to simulate the actual situation, cannot determine the failure of the object under test, and cannot conduct effective tests and other problems, to achieve uniform and rapid surface temperature, lower temperature, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

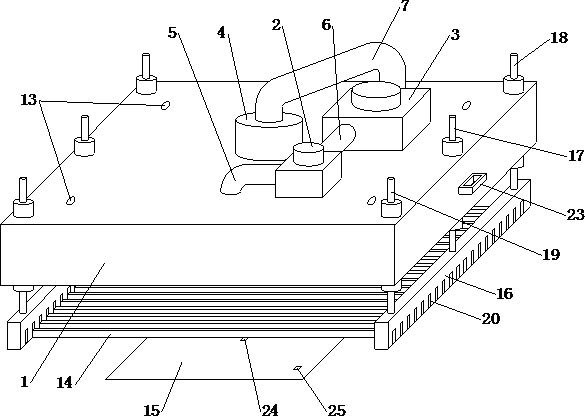

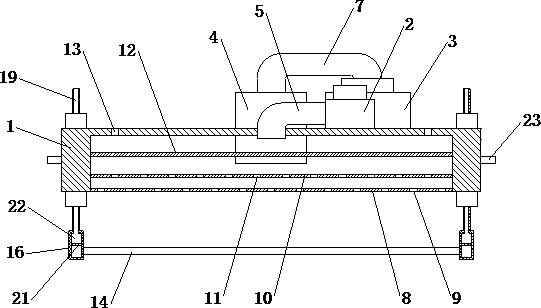

[0044] like figure 1 and figure 2 As shown in the figure, a temperature rise and fall control device for an aircraft aerodynamic thermal environment simulation test of the present invention includes a uniform air box 1, an air delivery mechanism arranged on the upper part of the uniform air box 1 for providing cold air, and an air distribution mechanism arranged on the uniform air box 1 The lower part of the box 1 is used for a heating mechanism for heating the test piece 15 , and the test piece 15 is provided with a first temperature sensor 24 for collecting the temperature of the test piece 15 .

[0045] The air distribution box 1 is a bottomless hollow box. The air distribution box 1 is provided with a first air distribution plate 8, a second air distribution plate 10 and a fixing plate 12 in sequence from bottom to top. The inner space is divided into a cooling layer at the upper part and a gas transport layer at the lower part by the fixing plate 12 , and the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com