Circuit board backdrill stub control method and circuit board

A control method and circuit board technology, applied in printed circuit manufacturing, printed circuit, electrical components, etc., can solve problems such as ultra-thin core board back-drilling processing yield and product quality defects, so as to improve product quality and production efficiency, The effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

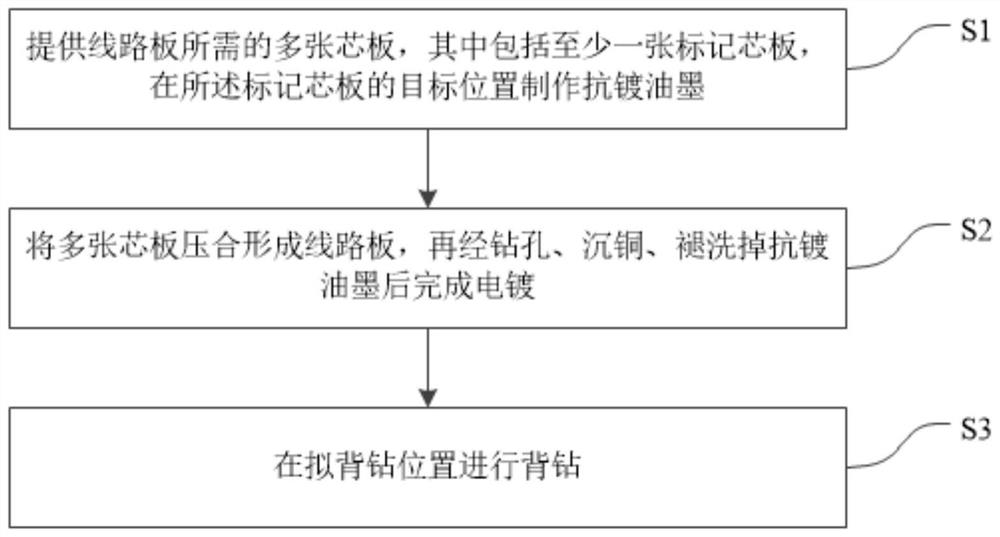

[0061] see figure 1 , the circuit board back drilling stub control method provided by the embodiment of the present invention includes the following steps:

[0062] Step S1 : providing a plurality of core boards required for the circuit board, including at least one marking core board, and making plating resist ink at the target position of the marking core board.

[0063] Among them, according to the different depth of the back-drilling, the marked core board can be the core board that should be drilled through the top layer of the core board and not the bottom layer of the core board in the back-drilling operation, or the core board that is closest to the back-drilling in the back-drilling operation. Core that is drilled through the layers and not through the top layer of the core.

[0064] Exemplarily, 7 core boards for making 16-layer circuit boards are provided, and the 7 core boards specifically include: 5 ordinary core boards, 1 marked core board 10 (such as figure 2 s...

Embodiment 2

[0094] The embodiment of the present invention provides a circuit board, which is processed and prepared by the above-mentioned circuit board back drilling stub control method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com