Tobacco leaf intelligent baking dynamic management method

A technology for dynamic management of tobacco leaves, applied in the fields of tobacco, tobacco processing, and tobacco preparation, etc., can solve the problems of high data processing hysteresis, decline in tobacco quality, instability, etc., achieve high quality, reduce tobacco loss rate, and simplify curing. The effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

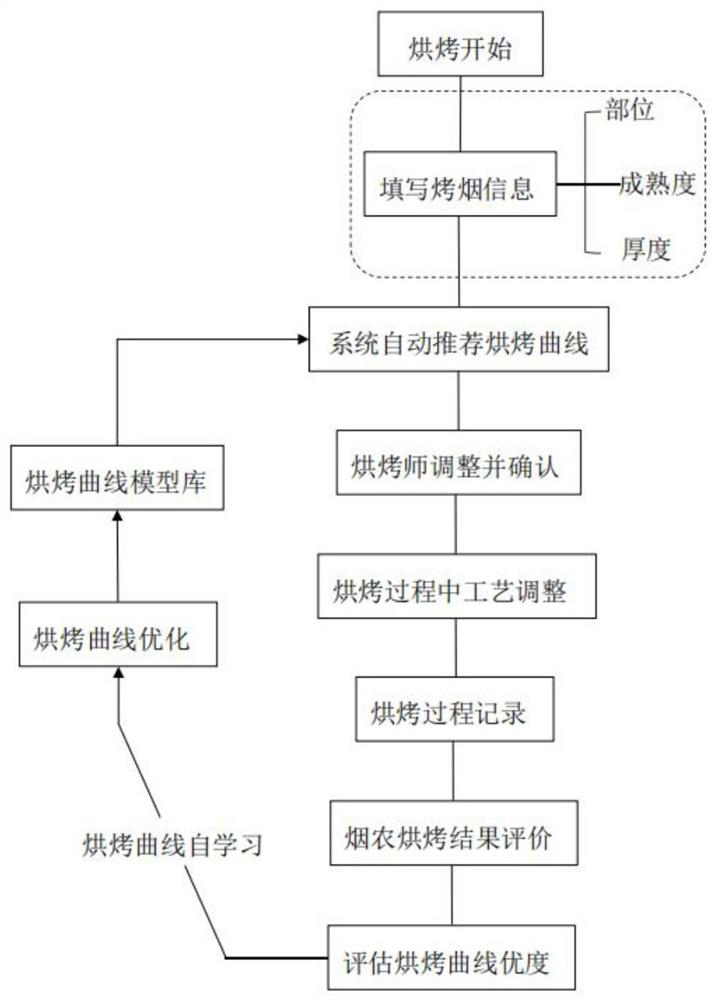

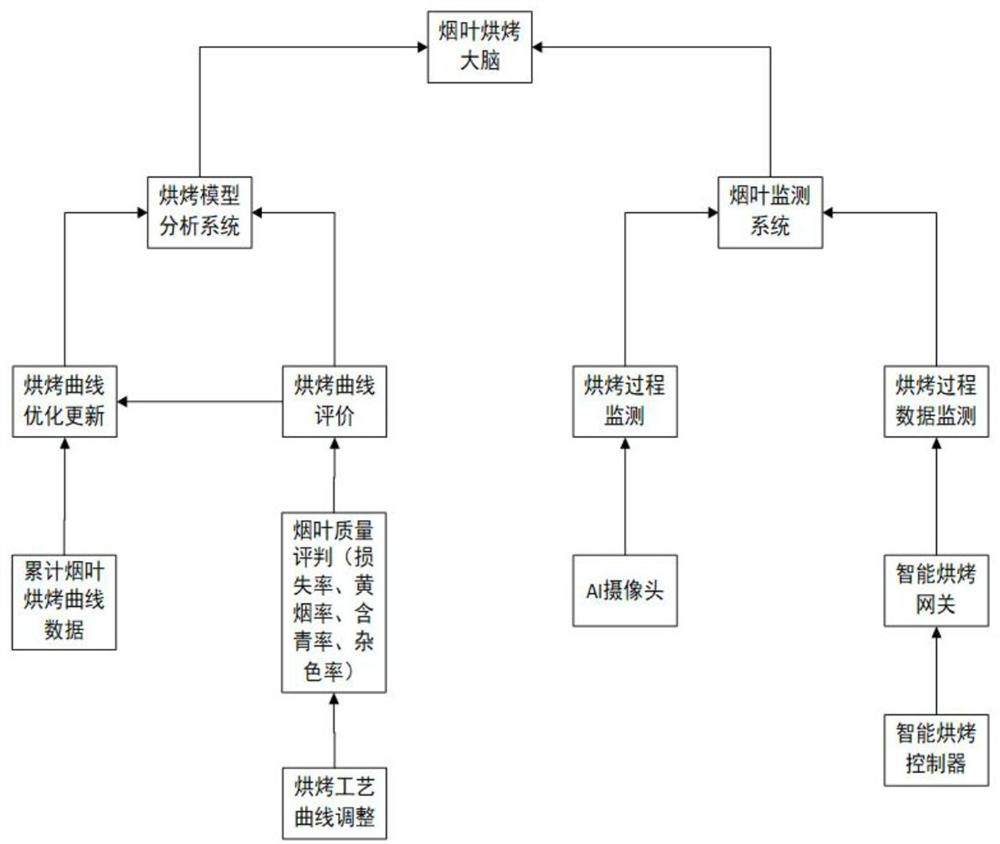

[0033] like figure 1 and figure 2 As shown, a method for dynamic management of tobacco leaf intelligent curing is based on the big data of the Internet of Things, and based on the existing technology, the Internet of Things platform, the tobacco leaf curing management platform, and the curing curve model analysis platform are deployed in the cloud. Cloud computing conducts data collection, feedback, analysis, and modeling, and finally forms a cloud-based decision-making model for tobacco curing and high-quality tobacco.

[0034] Tobacco leaf curing curve big data model database is established. Through data collection and accumulation, the characteristic quantities of tobacco leaves accumulated over the years are collected for big data analysis and modeling, and the dynamic model between the characteristic quantities of tobacco leaves, the curing temperature of each stage and the quality of tobacco leaves is established. Accumulate the data of tobacco leaf curing curve.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com