Machining method of crank pin and crank pin

A processing method and crank pin technology, applied in bolts and other directions, can solve problems such as material loss, and achieve the effect of reducing raw material loss and solving serious material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention are further described below, but the claimed scope is not limited to the description.

[0029] like Figure 1 to Figure 7 shown.

[0030] A processing method of a crank pin of the present invention comprises the following steps:

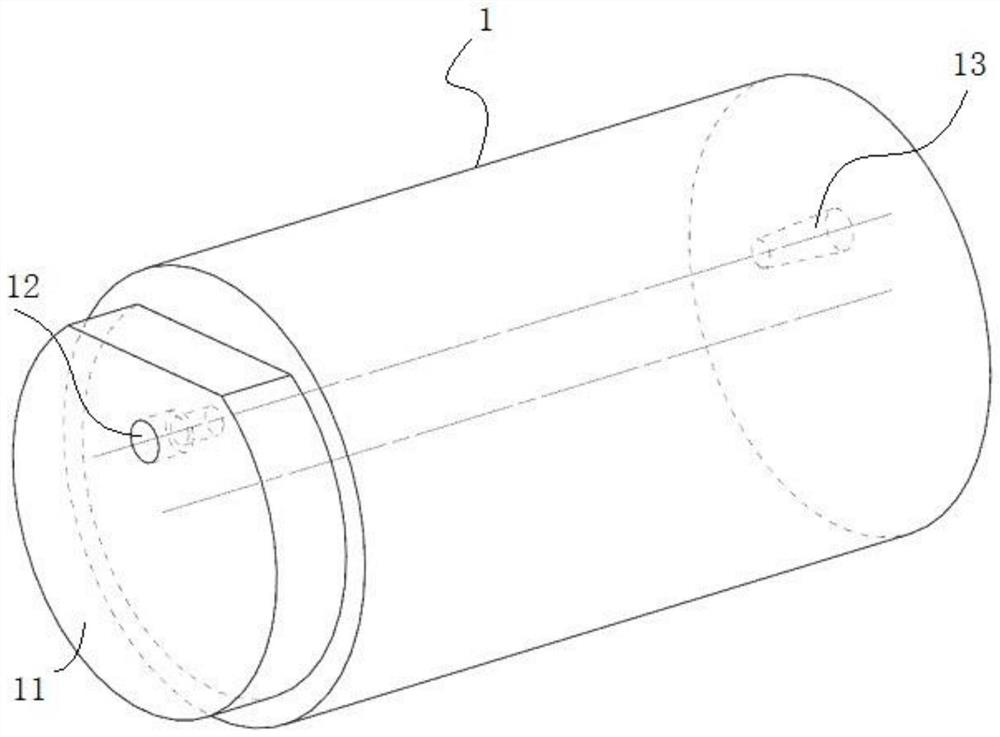

[0031] Step 1. Bar hoof forming: Take φ57 round bar 1, use a CNC milling machine to mill out the hoof table 11 at one end of the bar 1, and reserve the allowance for the maximum distance dimension of the head 51 of the crank pin 5 Processing, because the shoe-shaped table 11 needs to be processed to form the head 51 of the crank pin 5 in the later stage.

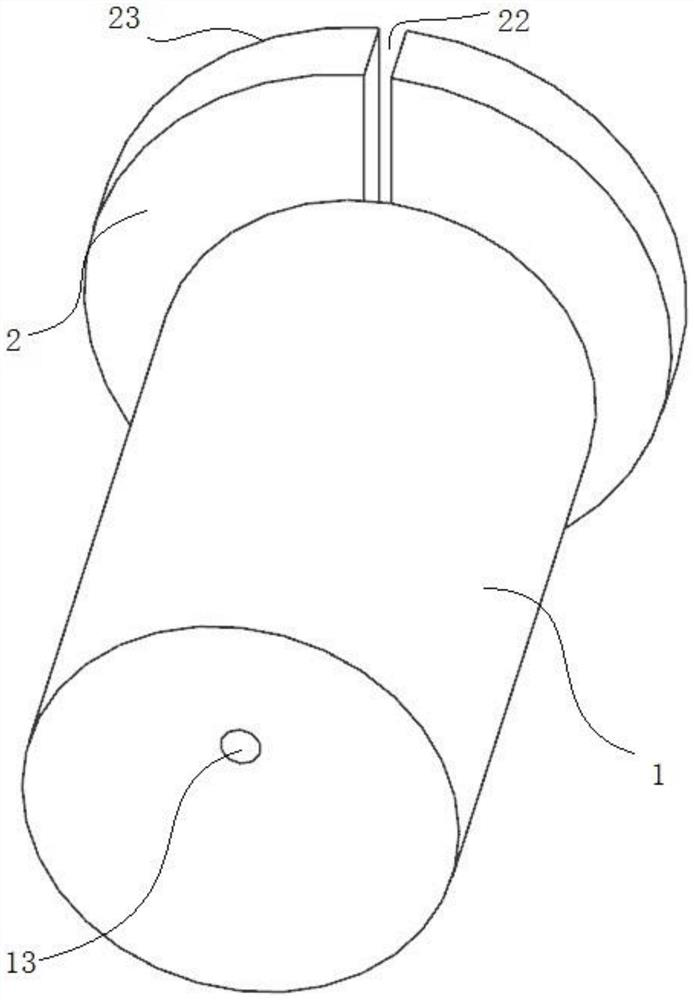

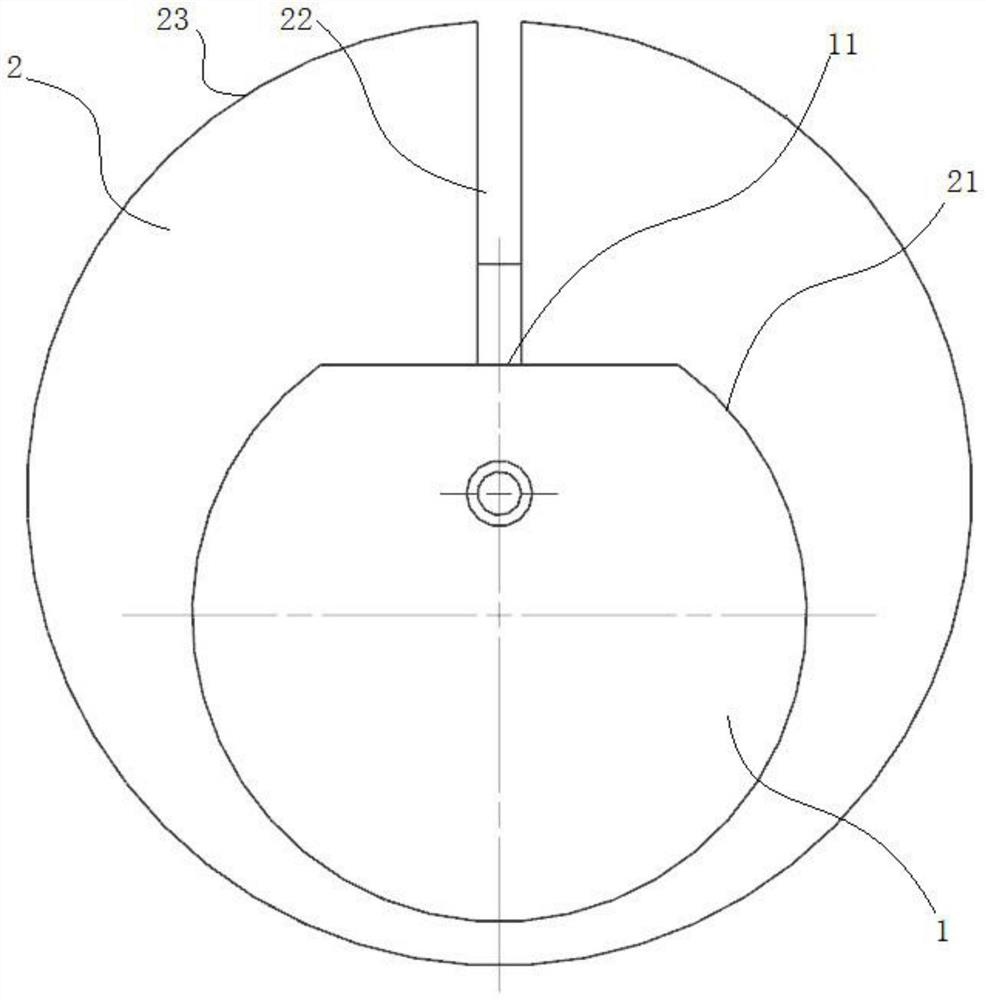

[0032] Step 2. Forming of the center hole: the hoof-shaped hole 21 of the hoof-shaped tooling body 2 is used to cooperate with the hoof-shaped table 11 of the bar 1, and the lathe clamp is clamped by clamping the outside of the hoof-shaped tooling body 2, and the hoof-shaped tooling body 2 is in the Under the deformation of the hoof-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com