Garbage compost scattering device

A technology of garbage composting and rotating pipes, which is applied in the directions of loading/unloading, transportation and packaging, biological organic part treatment, etc., can solve the problems of uneven fertilizer distribution, unbalanced nutrition, and high intermediate stacking, so as to avoid unbalanced compost nutrition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

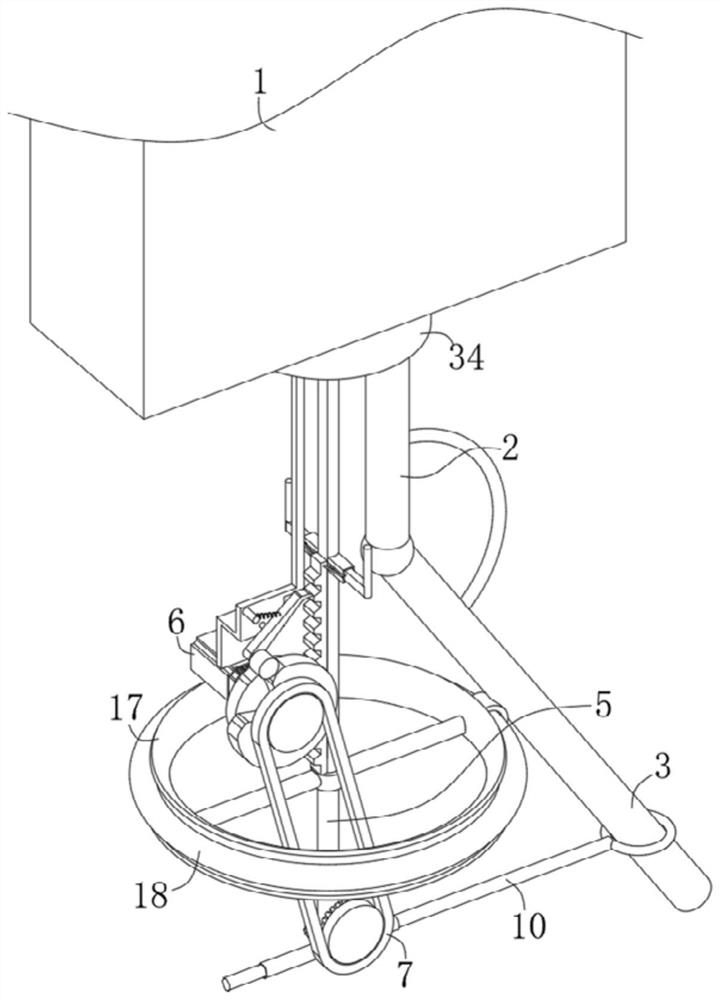

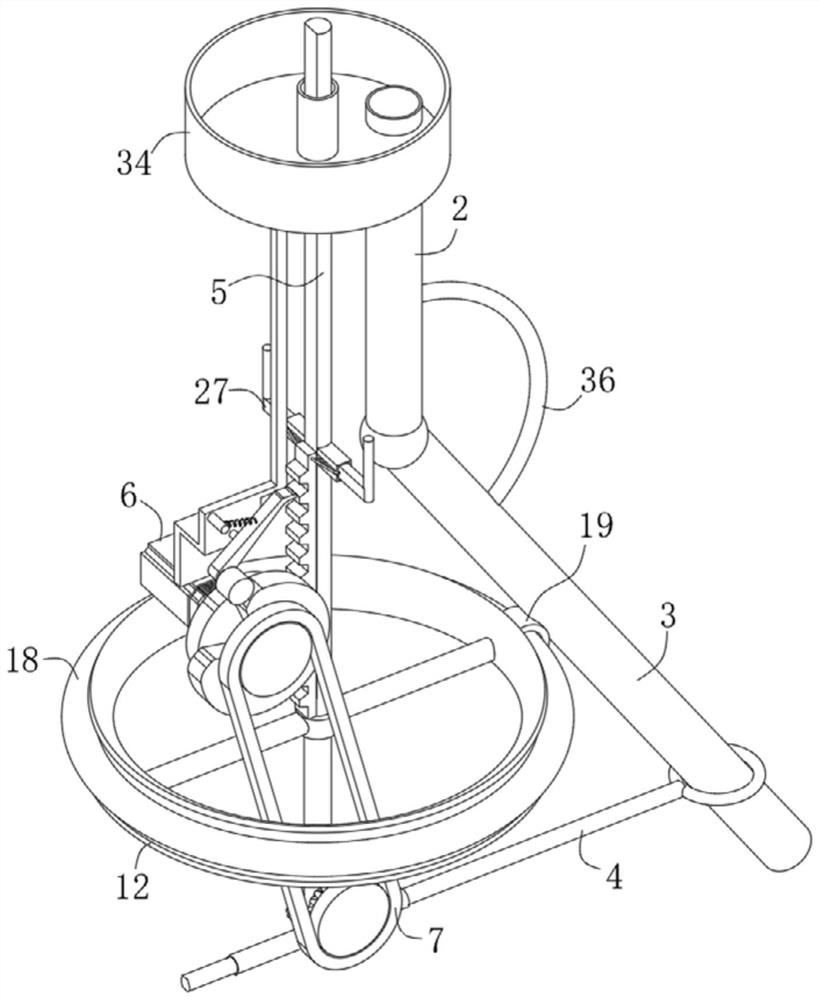

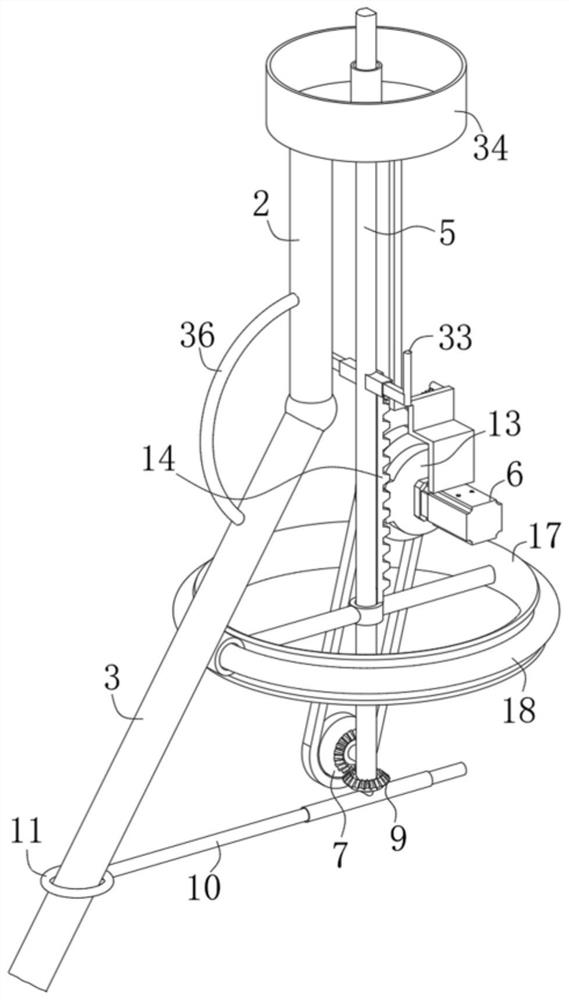

[0025] see Figure 1-Figure 3 , a garbage compost spreading device in the figure, including a body 1, the bottom of the body 1 is connected with a communication pipe 2 with softness, and the end of the communication pipe 2 is connected with a rotating pipe 3; It also includes a rotating assembly 4 for The rotating assembly 4 that drives the rotating pipe 3 to rotate in a circular motion is provided on the rotating pipe 3 ;

[0026] see Figure 4-Figure 6 , the rotating assembly 4 in the figure includes a fixed rod 5 connected and fixed with the body 1, the outer surface of the fixed rod 5 is fixedly connected with a servo motor 6 through a connecting plate, the output shaft of the servo motor 6 is fixedly connected with a transmission belt 7, and another rotation of the conveyor belt is fixed. The wheel is fixedly connected with a first bevel gear 8 that is rotatably connected to the fixed rod 5, the first bevel gear 8 is meshed with a second bevel gear 9 that is rotatably co...

Embodiment 2

[0032] see Figure 1-Figure 3 , a garbage compost spreading device in the figure, including a body 1, the bottom of the body 1 is connected with a communication pipe 2 with softness, and the end of the communication pipe 2 is connected with a rotating pipe 3; It also includes a rotating assembly 4 for The rotating assembly 4 that drives the rotating pipe 3 to rotate in a circular motion is provided on the rotating pipe 3 ;

[0033] see Figure 4-Figure 6, the rotating assembly 4 in the figure includes a fixed rod 5 connected and fixed with the body 1, the outer surface of the fixed rod 5 is fixedly connected with a servo motor 6 through a connecting plate, the output shaft of the servo motor 6 is fixedly connected with a transmission belt 7, and another rotation of the conveyor belt is fixed. The wheel is fixedly connected with a first bevel gear 8 that is rotatably connected to the fixed rod 5, the first bevel gear 8 is meshed with a second bevel gear 9 that is rotatably con...

Embodiment 3

[0038] see Figure 1-Figure 3 , a garbage compost spreading device in the figure, including a body 1, the bottom of the body 1 is connected with a communication pipe 2 with softness, and the end of the communication pipe 2 is connected with a rotating pipe 3; It also includes a rotating assembly 4 for The rotating assembly 4 that drives the rotating pipe 3 to rotate in a circular motion is provided on the rotating pipe 3 ;

[0039] see Figure 4-Figure 6 , the rotating assembly 4 in the figure includes a fixed rod 5 connected and fixed with the body 1, the outer surface of the fixed rod 5 is fixedly connected with a servo motor 6 through a connecting plate, the output shaft of the servo motor 6 is fixedly connected with a transmission belt 7, and another rotation of the conveyor belt is fixed. The wheel is fixedly connected with a first bevel gear 8 that is rotatably connected to the fixed rod 5, the first bevel gear 8 is meshed with a second bevel gear 9 that is rotatably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com