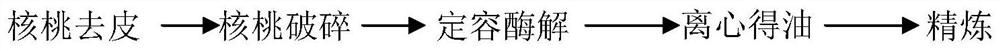

Method for preparing walnut oil by aqueous enzymatic method

A technology of walnut oil and water enzymatic method, which is applied in the directions of fat oil/fat production, fat oil/fat refining, and recovery of fatty substances, etc., can solve the problems of low oil yield and many steps, and achieves improved degreasing rate, good crushing effect, The effect of reducing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

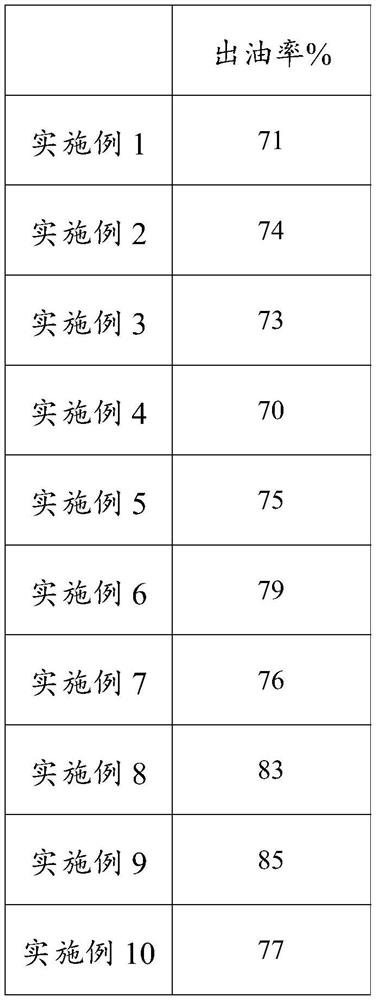

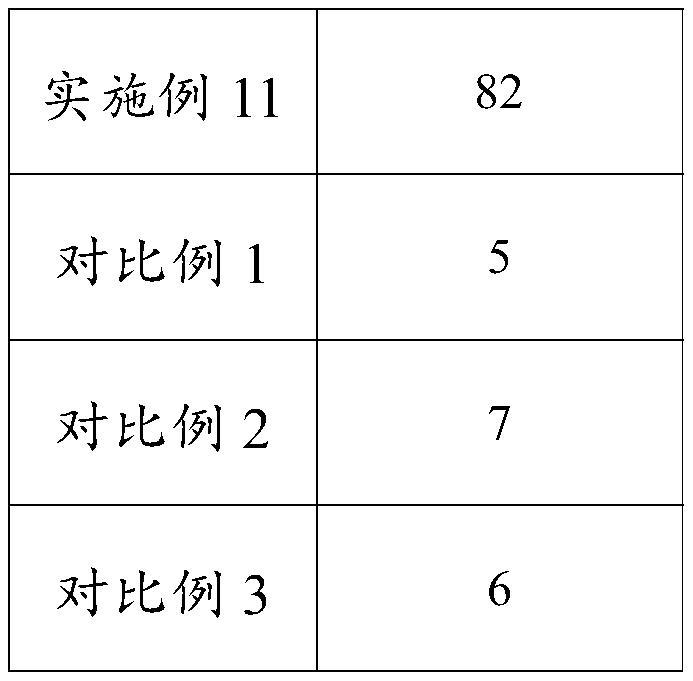

Examples

Embodiment 1

[0049] The present embodiment provides a method for preparing walnut oil by water enzymatic method, and the specific steps are as follows:

[0050] Step 1: Choose 500g of walnut kernels with full particles, no mildew, no oily smell, no pests, and no impurities.

[0051] Step 2: prepare an alkaline aqueous solution with a mass concentration of 4‰, add walnut kernels after boiling, time for 25 minutes, rinse the alkali-boiled walnut kernels with water, and after rinsing, the obtained peeled walnut kernels have a moisture content of 20%.

[0052] Step 3: Using a colloid mill to crush the pretreated walnut kernels without adding water, and the particle size of the walnut kernels after crushing does not exceed 900 μm.

[0053] Step 4: Add water to the crushed walnut kernels to prepare walnut pulp, and the mass ratio of walnut kernels to water is 1:3.

[0054] Step 5: heating the walnut pulp to 50°C, adding alkaline protease, stirring and mixing, the amount of alkaline protease add...

Embodiment 2

[0057] The present embodiment provides a method for preparing walnut oil by water enzymatic method, and the specific steps are as follows:

[0058] Step 1: Choose 500g of walnut kernels with full particles, no mildew, no oily smell, no pests, and no impurities.

[0059] Step 2: prepare an alkaline aqueous solution with a mass concentration of 4‰, add walnut kernels after boiling, time for 25 minutes, rinse the alkali-boiled walnut kernels with water, and after rinsing, the obtained peeled walnut kernels have a moisture content of 20%.

[0060] Step 3: Using a colloid mill to crush the pretreated walnut kernels without adding water, and the particle size of the walnut kernels after crushing does not exceed 900 μm.

[0061] Step 4: Add water to the crushed walnut kernels to prepare walnut pulp, and the mass ratio of walnut kernels to water is 1:3.

[0062] Step 5: Heat the walnut pulp to 50°C, add papain, stir and mix, and the amount of papain added is 3‰ of the mass of the wal...

Embodiment 3

[0065] The present embodiment provides a method for preparing walnut oil by water enzymatic method, and the specific steps are as follows:

[0066] Step 1: Choose 500g of walnut kernels with full particles, no mildew, no oily smell, no pests, and no impurities.

[0067] Step 2: prepare an alkaline aqueous solution with a mass concentration of 4‰, add walnut kernels after boiling, time for 25 minutes, rinse the alkali-boiled walnut kernels with water, and after rinsing, the obtained peeled walnut kernels have a moisture content of 20%.

[0068] Step 3: Using a colloid mill to crush the pretreated walnut kernels without adding water, and the particle size of the walnut kernels after crushing does not exceed 900 μm.

[0069] Step 4: Add water to the crushed walnut kernels to prepare walnut pulp, and the mass ratio of walnut kernels to water is 1:3.

[0070] Step 5: heating the walnut pulp to 50°C, adding neutral protease, stirring and mixing, the amount of neutral protease added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com