A method for color retention and degreasing of wood

A technology for wood and color retention, applied in the direction of wood impregnation, wood treatment, impregnated wood, etc., can solve the problems of hindering the application of pine solid wood products, dull luster, low degreasing rate, etc., to improve degreasing effect, avoid easy blackening, improve The effect of degreasing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

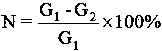

Examples

example 1

[0022] Soak the wood to be degreased in water for 2 hours, take it out, spray and freeze it with liquid nitrogen for 2 minutes, put the frozen wood in an oven, and dry it at 110°C for 30 minutes to obtain dry wood; put the dry wood into a blasting tank, Use a booster pump to pressurize the blasting tank until the pressure in the blasting tank reaches 0.8 MPa, keep the pressure for 3 minutes, open the exhaust valve of the blasting tank to reduce the pressure in the blasting tank to normal pressure instantly, and take out the wood, which is the pre-treatment process. Wood processing: Weigh the tea bran and put it into a ball mill jar, add zirconia ball milling beads into the ball mill jar according to the mass ratio of the ball to material at 20:1, grind for 30 minutes to obtain tea bran powder, and then mix the tea bran with a mass ratio of 1:10. Mix the bran powder and water, heat and boil for 2 hours to obtain the cooking solution; use a centrifuge to centrifuge the cooking so...

example 2

[0024] Soak the wood to be degreased in water for 1 hour, take it out, spray and freeze it with liquid nitrogen for 1 minute, put the frozen wood in an oven, and dry it at 105°C for 20 minutes to obtain dry wood; put the dry wood into a blasting tank, Use a booster pump to pressurize the blasting tank until the pressure in the blasting tank reaches 0.5 MPa, keep the pressure for 2 minutes, open the exhaust valve of the blasting tank to reduce the pressure in the blasting tank to normal pressure instantly, and take out the wood, which is the pre-treatment process. Wood processing: Weigh the tea bran and put it into a ball mill jar, add zirconia ball milling beads into the ball mill jar at a mass ratio of 20:1 to the ball mill, grind for 20 minutes to obtain tea bran powder, and then grind the tea bran at a mass ratio of 1:10. Mix the bran powder and water, heat and boil for 1 hour to obtain the cooking solution; use a centrifuge to centrifuge the cooking solution at a speed of 2...

example 3

[0026]Soak the wood to be degreased in water for 1 hour, take it out, spray and freeze it with liquid nitrogen for 1 minute, put the frozen wood in an oven, and dry it at 107°C for 25 minutes to obtain dry wood; put the dry wood into a blasting tank, Use a booster pump to pressurize the blasting tank until the pressure in the blasting tank reaches 0.7 MPa, keep the pressure for 3 minutes, open the exhaust valve of the blasting tank to reduce the pressure in the blasting tank to normal pressure instantly, and take out the wood, which is the pre-preparation process. Wood processing: Weigh the tea bran and put it into a ball mill jar, add zirconia ball milling beads into the ball mill jar at a mass ratio of 20:1 to the ball mill, grind for 25 minutes to obtain tea bran powder, and then grind the tea bran at a mass ratio of 1:10. Mix the bran powder and water, heat and boil for 1 hour to obtain the cooking solution; use a centrifuge to centrifuge the cooking solution at 2500r / min f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com