Sand dust environment-frictional wear dynamic test device

A technology of friction and wear and dynamic testing, applied in the direction of measuring devices, testing wear resistance, instruments, etc., can solve the problems of easy failure, easy equipment, time-consuming half an hour or even longer, and achieve low cost and equipment failure low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

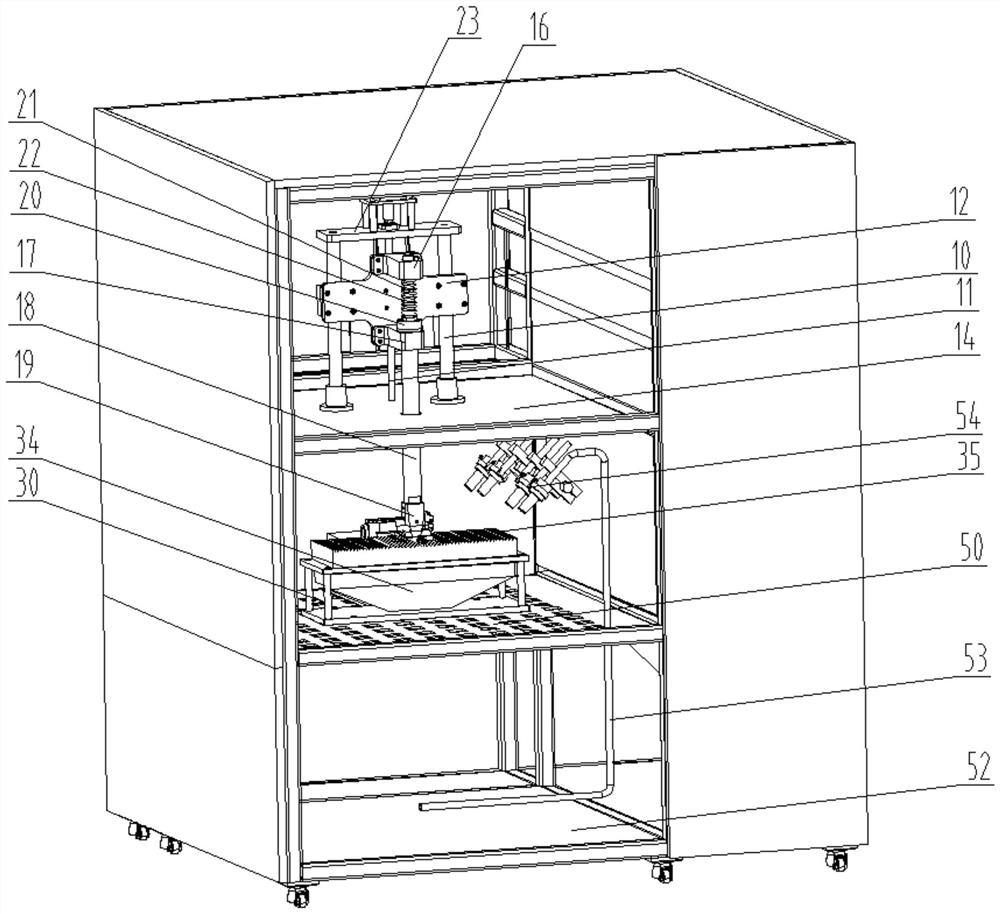

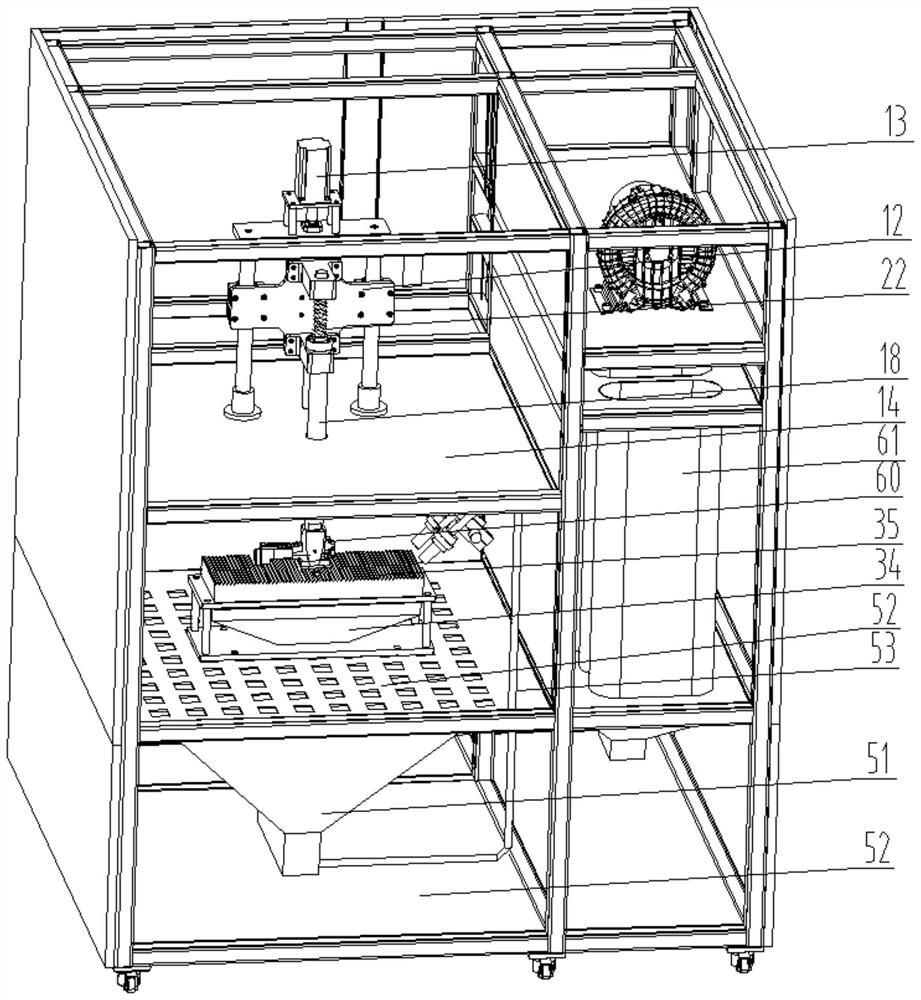

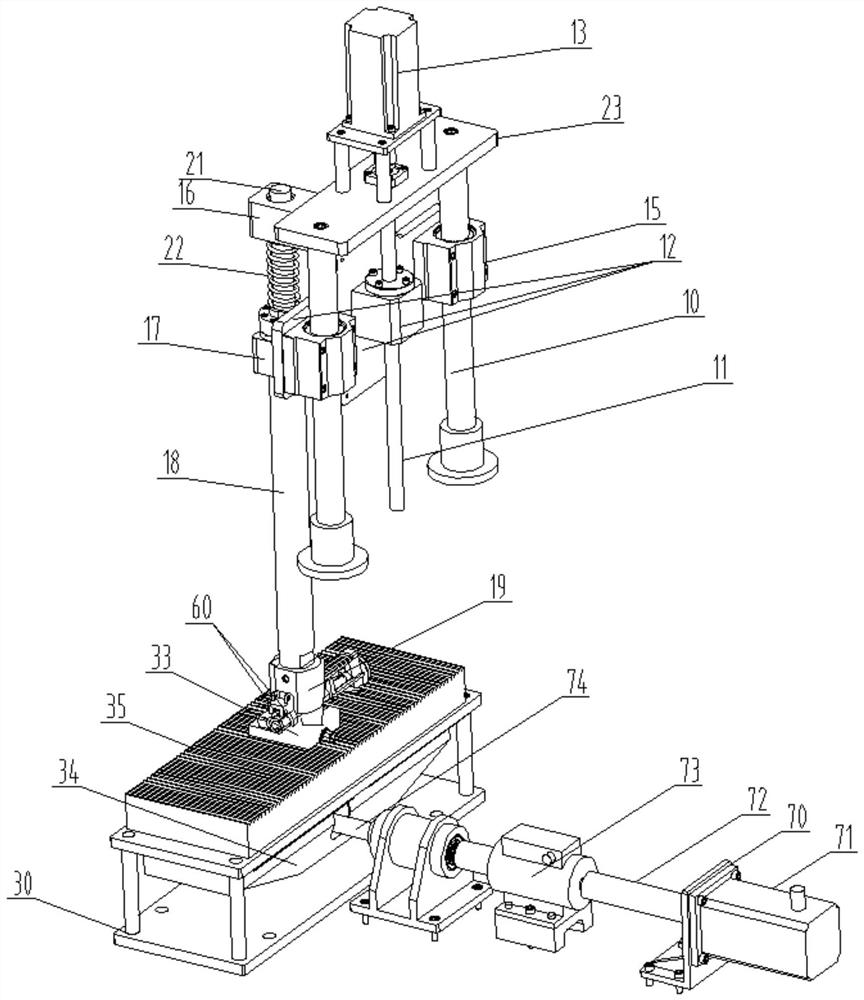

Embodiment 1

[0044] like Figure 1 to Figure 8 As shown, a sand-dust environment-friction and wear dynamic test device includes a box that can be completely closed, a power system and a sandblasting system arranged in the box, the power system is connected to a friction and wear component, and the upper part of the friction and wear component is connected to a loading system, There is a sand return system below the friction and wear components; the inner cavity of the box is divided into four independent closed spaces by a partition plate, the loading system is set in the upper space, the friction and wear components are set in the middle space, and the sand return system is set in the lower space , the dust collection system 61 is arranged in the side space, and the dust collection system 61 communicates with the central space. like Figure 8 As shown in the figure, the box is made by combining the library plate and the frame, the outside is the library plate, the inside is the frame, th...

Embodiment 2

[0060] A kind of sand and dust environment-friction and wear dynamic test device, with reference to embodiment 1, the main difference between it and embodiment 1 is embodied in software, specifically, the processor of the computer control device implements the following steps / functions when executing the program:

[0061] S1, control the servo motor 13 of the loading system to run in the forward direction, and control the servo motor 13 to stop when the loading force fed back by the pressure sensor 20 reaches the preset value;

[0062] S2, controlling the drive motor (ie the servo motor 71 ) of the power system to rotate at a preset rotational speed, thereby driving the sliding seat 32 and the lower clamp 33 to reciprocate at a preset frequency in the horizontal direction;

[0063] S3, control the servo motor 13 of the loading system to run alternately forward and reverse according to the preset frequency;

[0064] S4, control the sand blasting system and the dust collection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com