Image capture test device for damage process of pressure-bearing model and use method of image capture test device

A technology of image capture and test device, which can be used in measuring devices, using stable tension/pressure to test the strength of materials, reducing greenhouse gases, etc. To achieve the effect of convenient operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

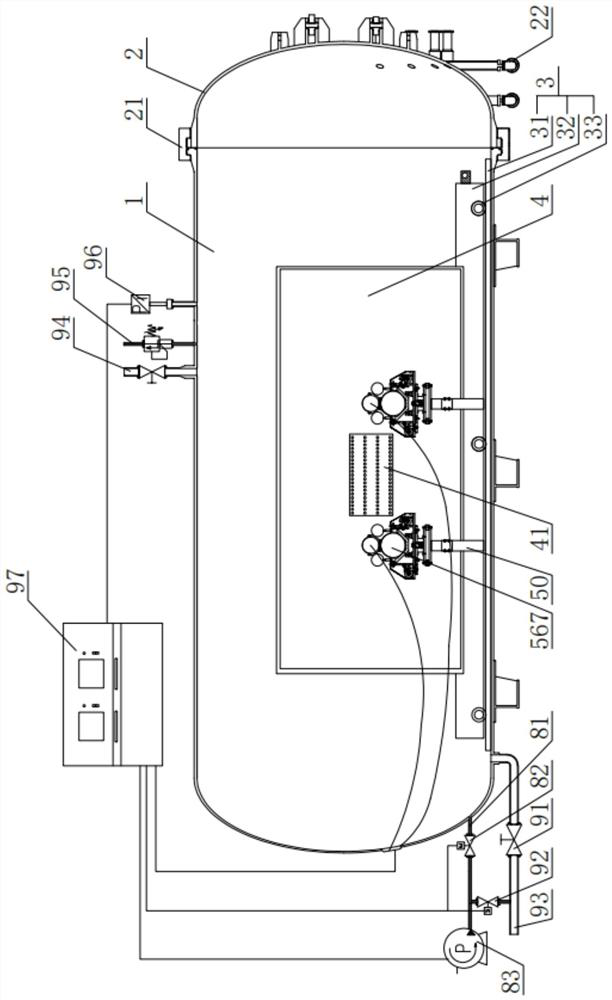

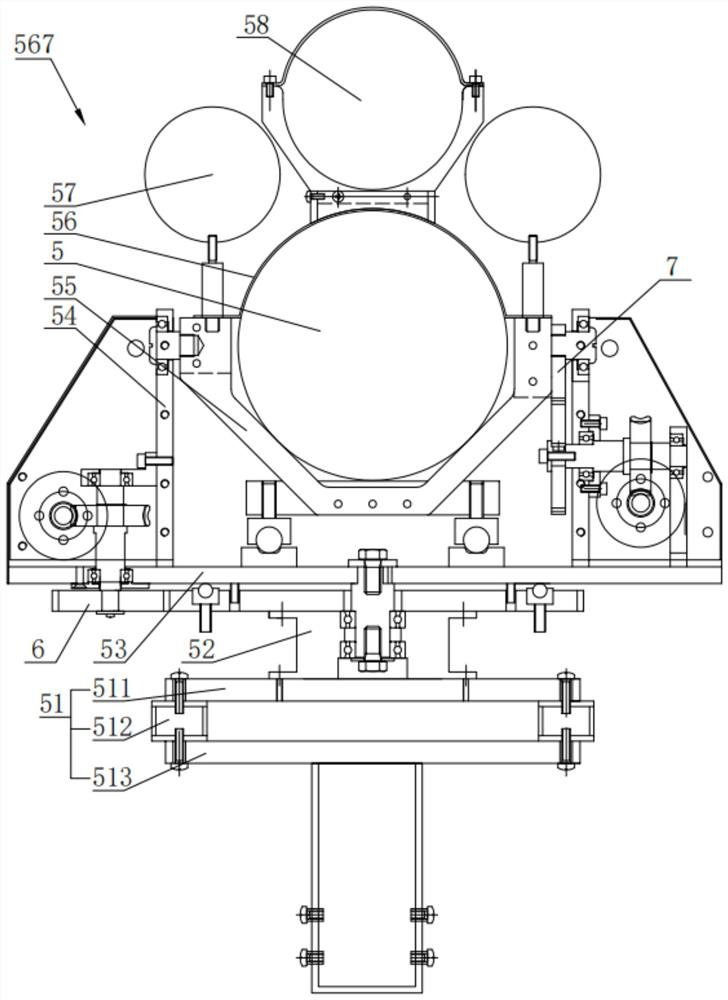

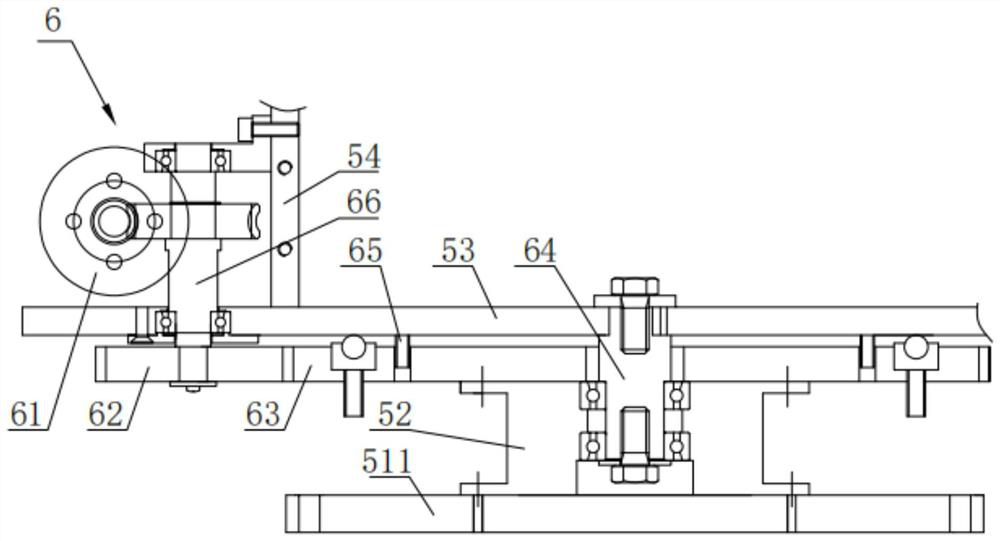

[0049] like figure 1 and figure 2 As shown in the figure, an image capture test device for the failure process of a pressure-bearing model in this embodiment includes a pressure chamber 1, and the open end of the pressure chamber 1 is equipped with a hatch cover 2 to form a closed space; There are more than two sets of image capture devices 567 fixed in the interior of the space facing the destruction area 41 of the test model 4, and the underwater high-speed camera 5 in the image capture device 567 is driven by the adjustment mechanism to adjust the position of the imaging field of view 500 relative to the destruction area 41; It also includes an injection and drainage system for injecting and draining water into the confined space outside the test model 4, and a pressurization system for pressurizing the confined space; a pressure sensor 96 for me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com