Ultrahigh-stability oxygen reduction catalyst for room-temperature hydrogen fuel cell

A fuel cell, stable technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of high cost of platinum, no decline in ORR electrocatalyst activity, slow electrocatalyst kinetics, etc., and achieve a simple, mild and excellent synthesis method The effect of catalytic performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

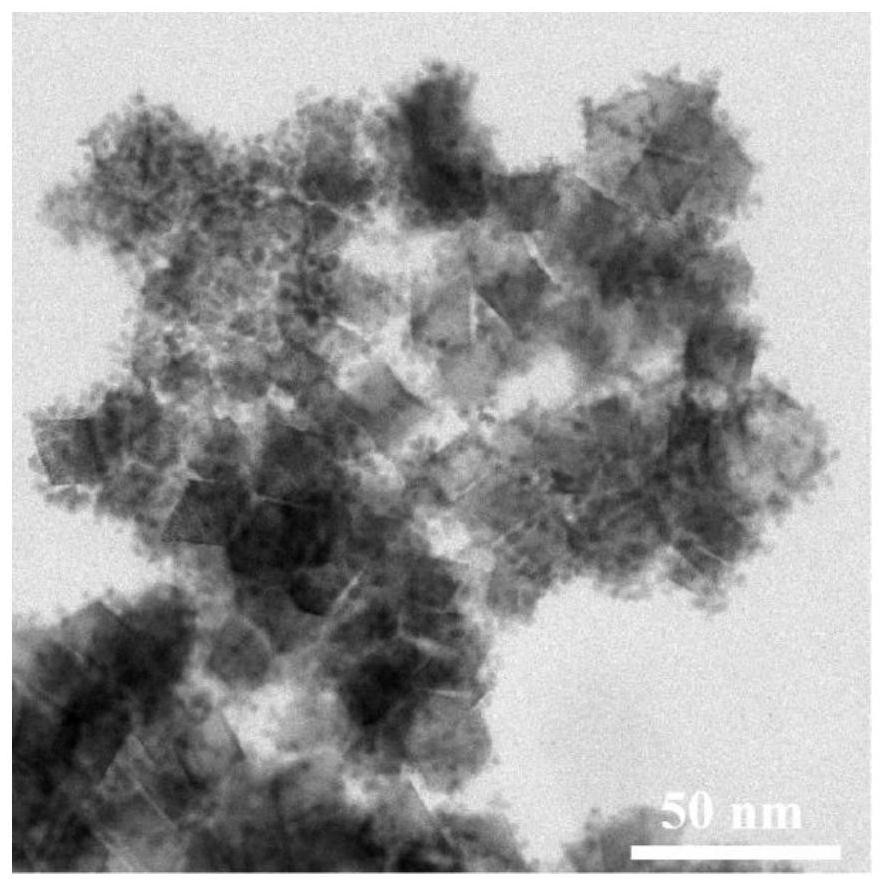

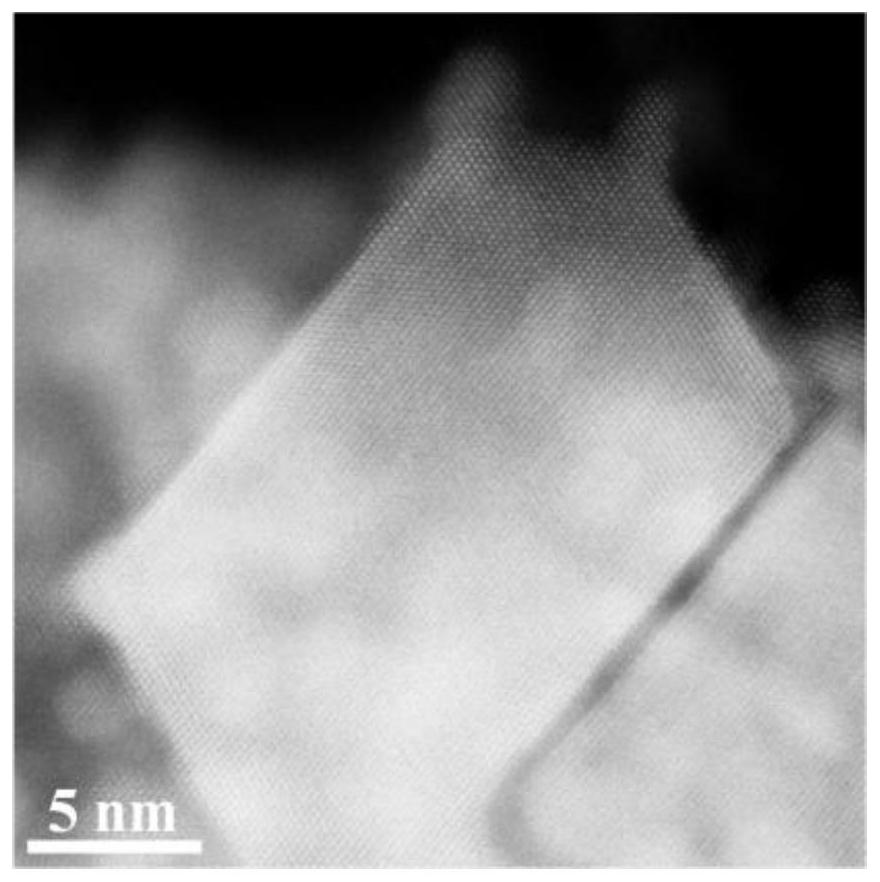

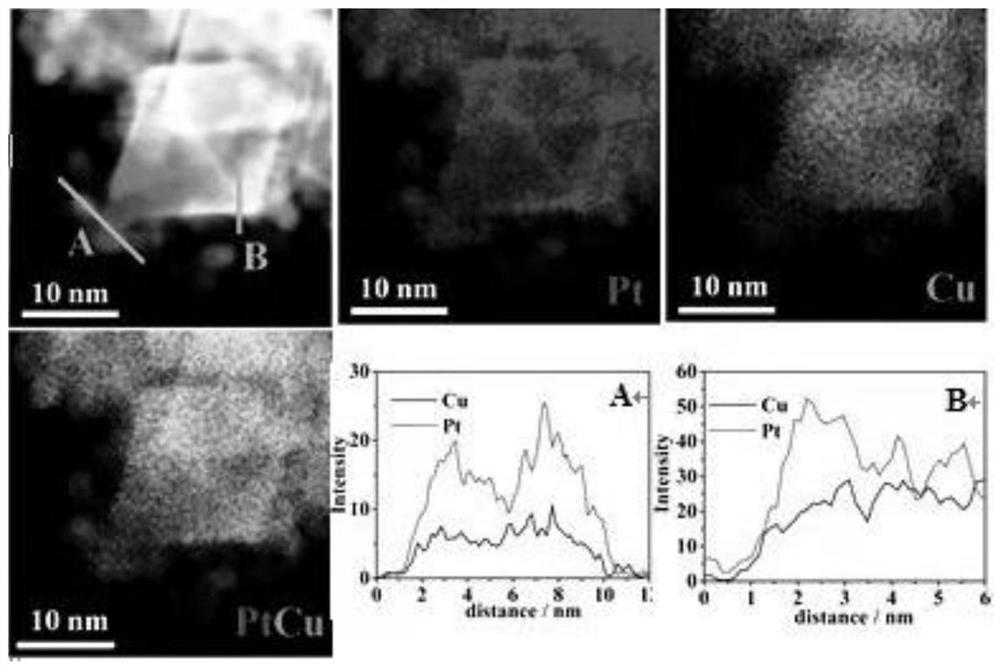

Method used

Image

Examples

Embodiment 1

[0019] (1) Synthesize PtCu octahedral alloy and store in water;

[0020] (2) take by weighing 20mg ascorbic acid and 20mg polyvinylpyrrolidone in the three-necked flask, and add the PtCu octahedral alloy (0.02mmol) gained in step (1), add 5mL ultrapure water, stir at room temperature;

[0021] (3) adding 9uL of chloroplatinic acid (0.1M) to the mixed solution in step (2), and reacting in an oil bath at 100° C. for 2 hours;

[0022] (4) The product obtained in step (3) is cooled, washed, and centrifuged to obtain a PtCu alloy, and the sample is dispersed and stored in ethanol.

Embodiment 2

[0024] (1) Synthesize PtCu octahedral alloy and store in water;

[0025] (2) take by weighing 20mg ascorbic acid and 20mg polyvinylpyrrolidone in the three-necked flask, and add the PtCu octahedral alloy (0.02mmol) gained in step (1), add 5mL ultrapure water, stir at room temperature;

[0026] (3) 12.5uL of chloroplatinic acid (0.1M) was added to the mixed solution in step (2), and the reaction was carried out in an oil bath at 100° C. for 2 hours;

[0027] (4) The product obtained in step (3) is cooled, washed, and centrifuged to obtain a PtCu alloy, and the sample is dispersed and stored in ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com