Process for preparing composite N-P-K fertilizer directly from urea solution

A compound fertilizer, NPK technology, applied in the field of direct preparation of NPK compound fertilizer from urea solution, can solve the problems of increasing equipment and energy consumption, complicating the production process, etc., to reduce the load, improve the appearance of particles, and simplify the production. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

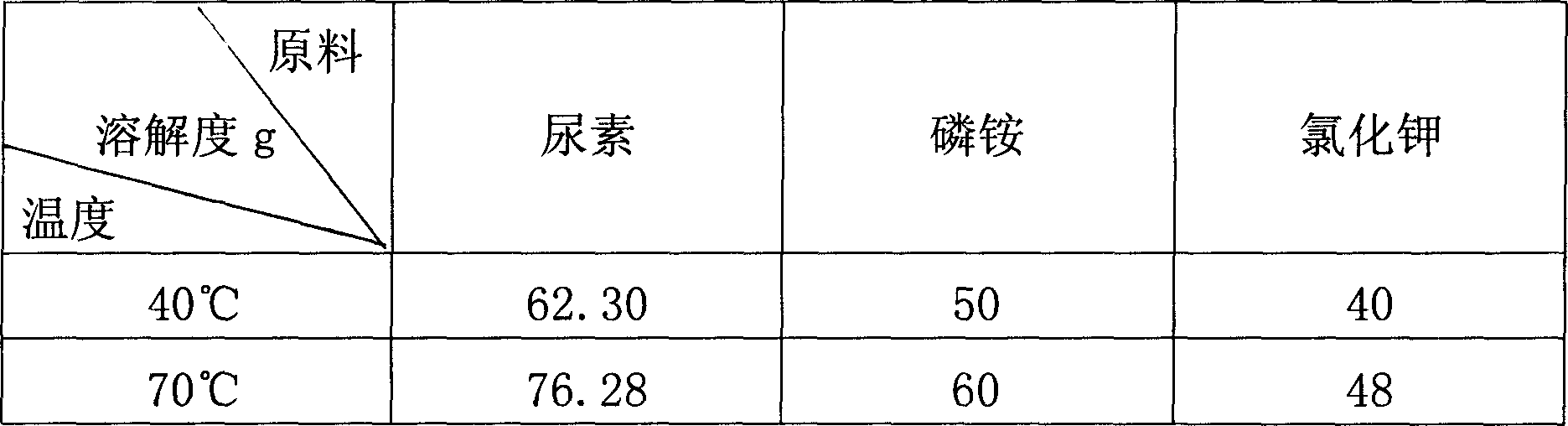

Method used

Image

Examples

Embodiment 1

[0031] Concentration is 95% by weight, temperature is 260 grams of urea solution of 123 ℃, pumps into in the drum granulator, powdery ammonium phosphate (containing N 11%, P 2 o 543%) 360 grams, potassium chloride (containing K 2 (260%) 250 grams, potter's clay 140 grams, through the granulation of about 6 minutes, 68.9 ℃ of temperature of granulated material, the moisture content when granulated material goes out granulator mouth is 1.97%, and 93% of balling rate. The granulated material is dried with hot air at a temperature of about 150°C, and the dried material is cooled and sieved to obtain a compound fertilizer with a particle size of 1-4.75mm. Fertilizer product analysis results: N 14.86%, P 2 o 5 15.05%, K 2 O 15.13%, total available nutrients (N+P 2 o 5 +K 2 O)=45.04%, the moisture content of the fertilizer is 0.95%, the strength is 29 Newtons, and the balling rate is 91.5%.

Embodiment 2

[0033] Concentration is 95% by weight, temperature is 400 grams of urea solution of 123 ℃, pumps into the drum granulator, powdery ammonium phosphate (containing N 11%, P 2 o 5 43%) 280 grams, potassium chloride (containing K 2 O 60%) 250 grams, 85 grams of bentonite, through about 12 minutes of granulation, the granulation material temperature was 71.2 ℃, and the moisture content when the granulation material went out of the granulator mouth was 2.05%, and the pelleting rate was 94%. The final material is dried with hot air at a temperature of about 150°C, and the dried material is cooled and sieved to obtain a compound fertilizer with a particle size of 1-4.75mm. Fertilizer product analysis results: N 20.10%, P 2 o 5 12.08%, K 2 O 15.25%, total available nutrients (N+P 2 o 5 +K 2 O)=47.43%, the moisture content of the fertilizer is 1.01%, the strength is 34 Newtons, and the pelleting rate is 92.0%.

Embodiment 3

[0035] Concentration is 70% by weight, temperature is 250 grams of urea solution of 80 ℃, squeezes in the drum granulator with pump, has calcium magnesium phosphate fertilizer (containing P 2 o 5 14%, H 2 O 1%) 500 grams, white fertilizer (containing P 2 o 5 30%, H 2 O 3%) 70 grams, potassium sulfate (containing K 2 O 50%, H 2 (01%) 160 grams, 80 grams of chicken manure that is dried and finely ground, through about 20 minutes of mixing and granulation, the material after granulation is dried with hot air at a temperature of 120~180° C., and the material after drying is cooled, After sieving, compound fertilizers with a particle size of 1-4.75mm are obtained. Fertilizer product analysis results: N 8.00%, P 2 o 5 9.05%, K 2 O 8.10%, total available nutrients (N+P 2 o 5 +K 2 O)=25.15%, the moisture content of the fertilizer is 2.49%, the strength is 15 Newtons, and the pelleting rate is over 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com