Film-like composite structure and method of manufacture thereof

A structure and film-like technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, instruments, etc., can solve problems such as failure to obtain film structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

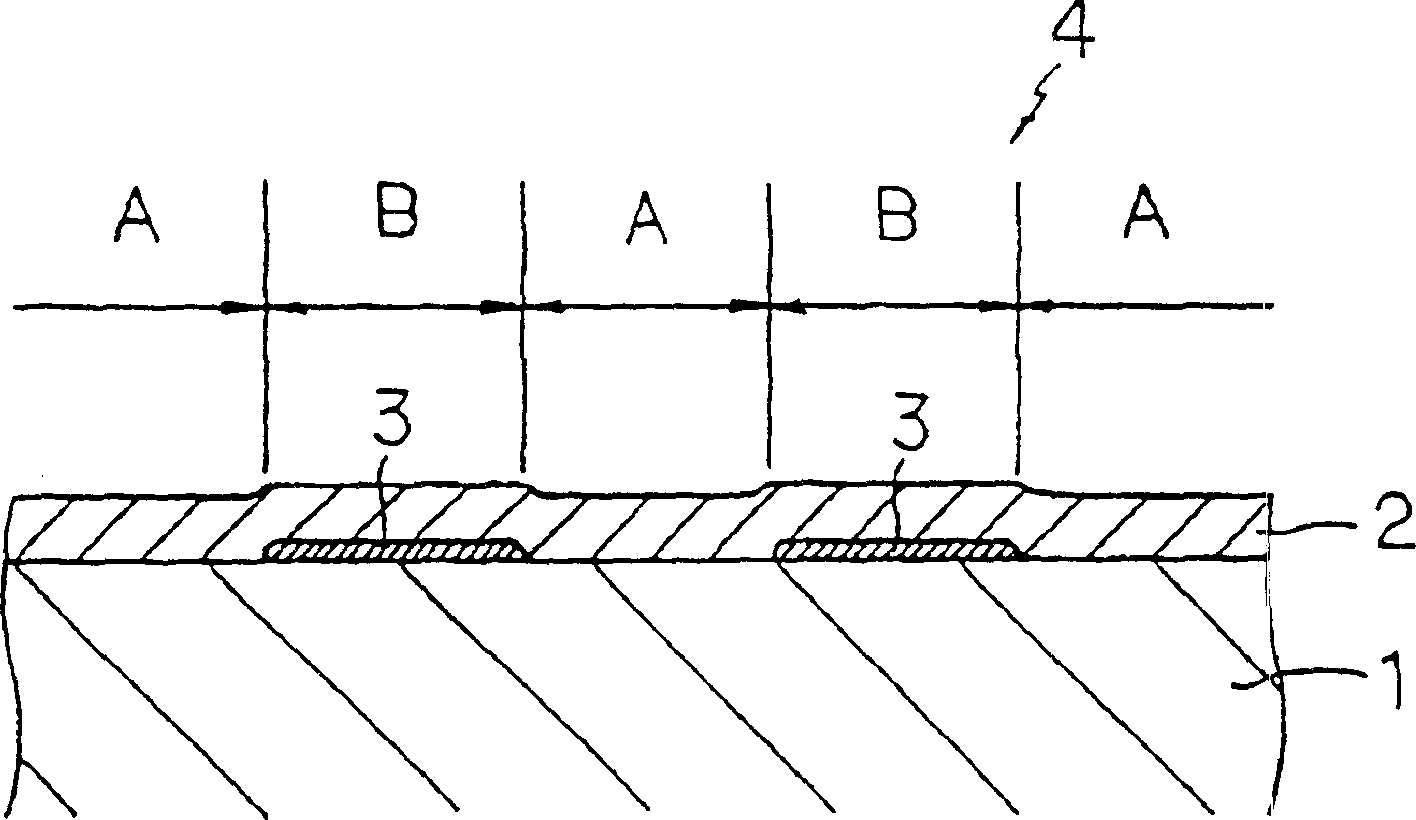

[0067] First, using a Si(111)·(7×7) substrate as the semiconductor layer 1, the size of the platform on the surface of the Si substrate is controlled to about 50nm. On the surface of a clean Si(111)·(7×7) substrate having such a mesa, first, an Au film with a thickness of 1 nm was formed by the MBE method while controlling the substrate temperature to 303K. Next, while controlling the substrate temperature to 303K, an Ag film with a thickness of 10 nm was formed by the MBE method. Here, an Au film is formed as the intermediate layer 3 , and an Ag film formed thereon serves as the metal layer 2 .

[0068] When performing STM observation and BEEM observation of such a composite film, it was confirmed that the Au film exists as an island on the platform, the region where Ag forms the interface with the Si substrate and the presence of an Au intermediate layer and the Au formation A region coexisting at the interface with the Si substrate. It was confirmed from the BEEM images ...

Embodiment 2

[0071] Using a Si(111)·(7×7) substrate as the semiconductor layer 1, on the surface of the cleaned Si(111)·(7×7) substrate, first, while controlling the substrate temperature to 973K, Formation of CaF as an insulator with a thickness of 1nm by the MBE method 2 membrane. The CaF 2 The membrane grows in bands from the steps. Secondly, the substrate temperature is controlled to 303K, and the CaF 2 The film was formed as an Au film with a thickness of 5.0 nm. Here, the CaF 2 A film is formed as the intermediate layer 3 , and the Au film formed thereon becomes the metal layer 2 .

[0072] When STM observation and BEEM observation of such a composite film were performed, it was confirmed that the region where the Au film forms a direct interface with the Si substrate and the band-shaped CaF with a thickness of 1 nm 2 A region where the film intervenes at the Au-Si interface coexists. It was confirmed from the BEEM spectra of these regions that the Schottky barrier heights are...

Embodiment 3

[0074] A Si(111)·(7×7) substrate was used as the semiconductor layer 1, and the size of the mesa on the surface of the Si substrate was controlled to about 50 nm by oxidation treatment in the atmosphere and heat treatment in ultra-high vacuum. On the surface of a clean Si(111)·(7×7) substrate with such a platform, first, while controlling the substrate temperature to 773K, a CaF as an insulator with a thickness of 1 nm was formed by the MBE method. 2 membrane. Secondly, the substrate temperature is controlled to 303K, and the CaF 2 The film was formed as an Au film with a thickness of 5.0 nm. Here, the CaF 2 A film is formed as the intermediate layer 3 , and the Au film formed thereon becomes the metal layer 2 .

[0075] When performing STM observation and BEEM observation of such a composite film, it was confirmed that the CaF 2 The membrane exists as islands on the platform with a thickness of 1 nm of CaF 2 A region where the film intervenes at the Au-Si interface and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com