Pressure sensor with electrostatic bonding and sealed capacitor cavity and its preparing process

A pressure sensor, electrostatic bonding technology, applied in the direction of fluid pressure measurement using capacitance changes, etc., can solve the problems of poor anti-interference ability of the sensor, unsatisfactory effect, large temperature influence, etc., and achieve good structural stability and versatility , The effect of the ideal zero pressure characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

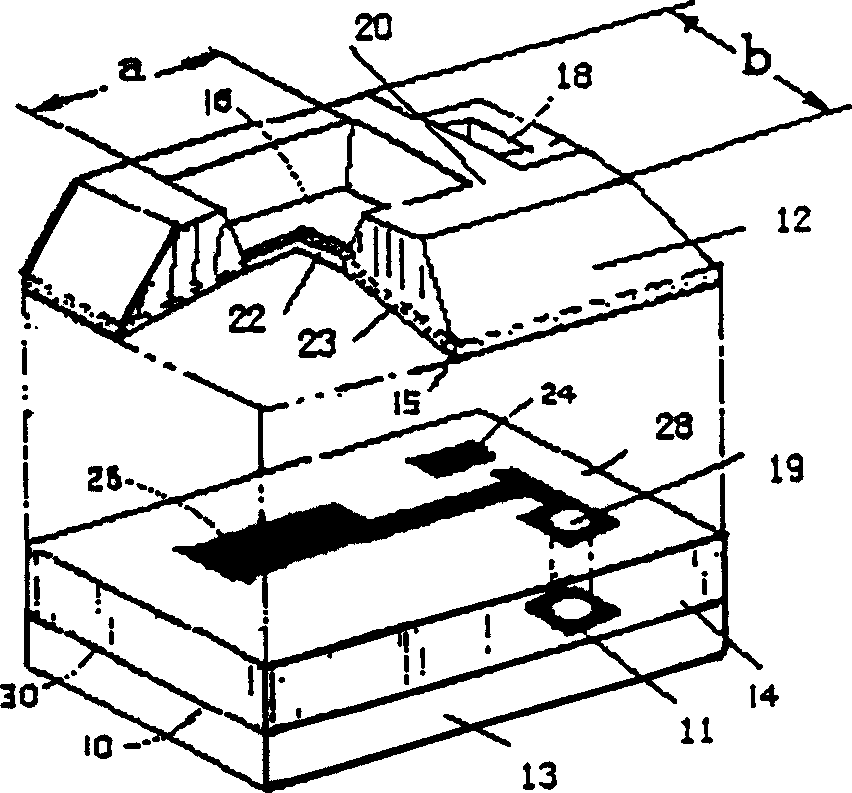

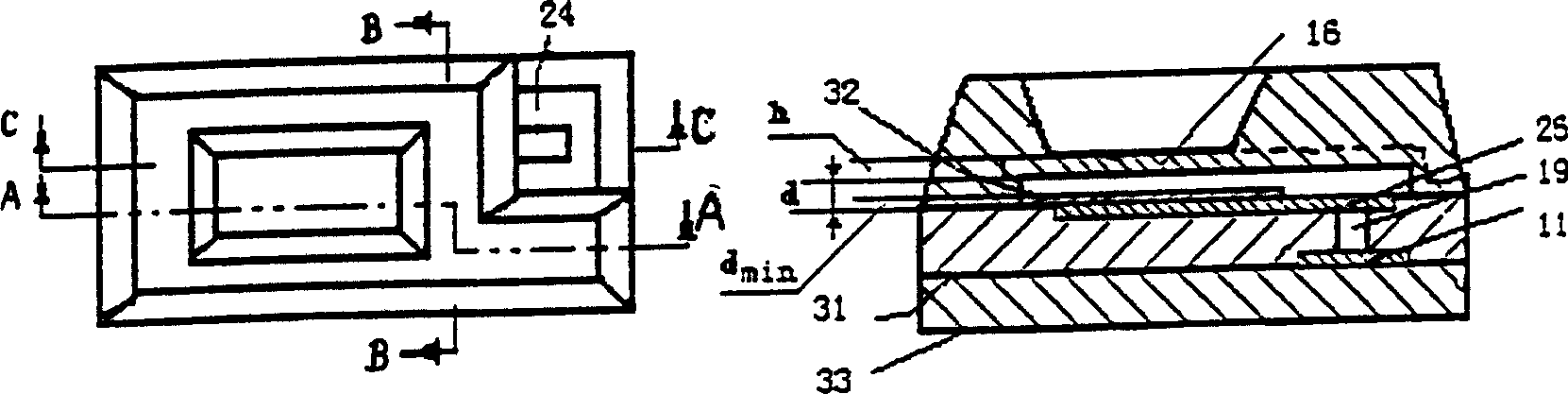

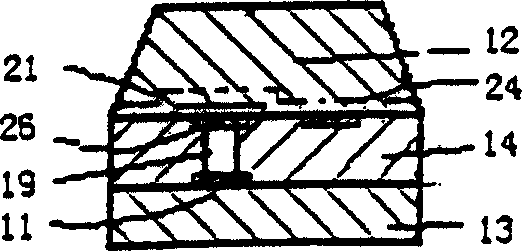

[0032] Such as figure 1 As shown, the pressure sensor of the electrostatically bonded sealed capacitor cavity is provided with one, an upper silicon chip 12 with a sensing film, the other is a glass substrate 14 with electrodes, and the third is a silicon chip (called a sealed silicon chip) used to seal the capacitor cavity. sheet) 13. There is a layer of P on the lower surface of the upper silicon wafer 12 + The diaphragm 15 formed by etching technology or PN junction chemical etching technology, the silicon diaphragm can be square or circular, and the pressure sensing diaphragm 16 is on this layer, which is a part of the diaphragm 15 . The sensory membrane 16 on the upper silicon wafer 12 is surrounded by a partition wall 20 . An opening 18 is also provided on the upper silicon wafer 12 . The pressure sensing membrane 16 is separated from the opening 18 by a partition wall 20 . The capacitor cavity 22 is made by photolithography and etching on the lower surface of the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Via hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com