Hydraulic driver of internal combustion engine

An internal combustion engine and hydraulic technology, applied in valve devices, machines/engines, mechanical equipment, etc., can solve the problems of complex transmission, poor manufacturability, and high cost, and achieve the effects of flexible installation parts, easy electronic control, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

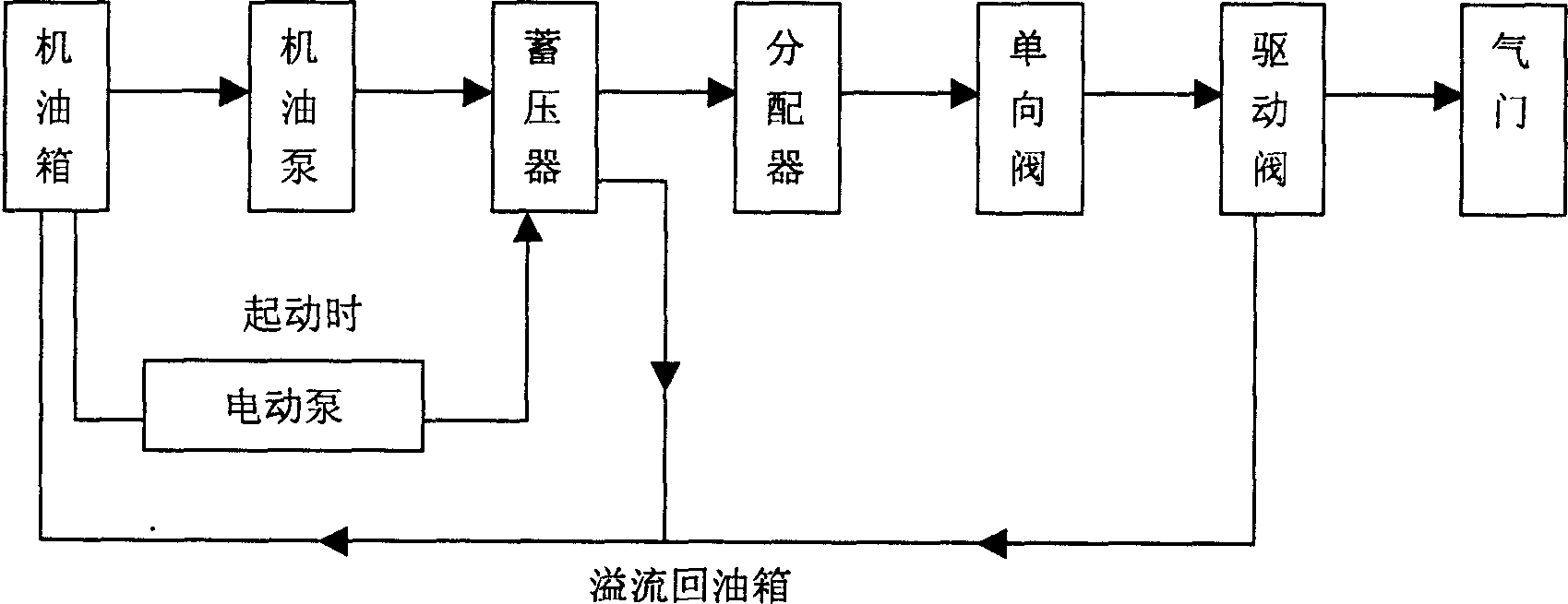

[0011] Such as figure 1 Shown, the specific work process of the present invention is: 1. machine oil is sent into pressure accumulator by electric pump (when starting) or machine oil pump (during normal operation); Through the mechanically driven timing distributor, the high-pressure oil is sent to the driving valve corresponding to a certain cylinder valve at a certain time, and lasts for a certain time; 3. Under the action of oil pressure, the driving valve overcomes the force of the spring and the force of the valve Under the pressure of the gas, the valve is driven according to a certain rule, so as to realize the opening and closing of the valve on time. A one-way valve is installed between the distributor and the drive valve to avoid backflow of high-pressure oil, excessive pressure loss and reduce system action hysteresis. The oil overflowing from the pressure accumulator, drive valve, etc. will flow back to the oil tank by itself.

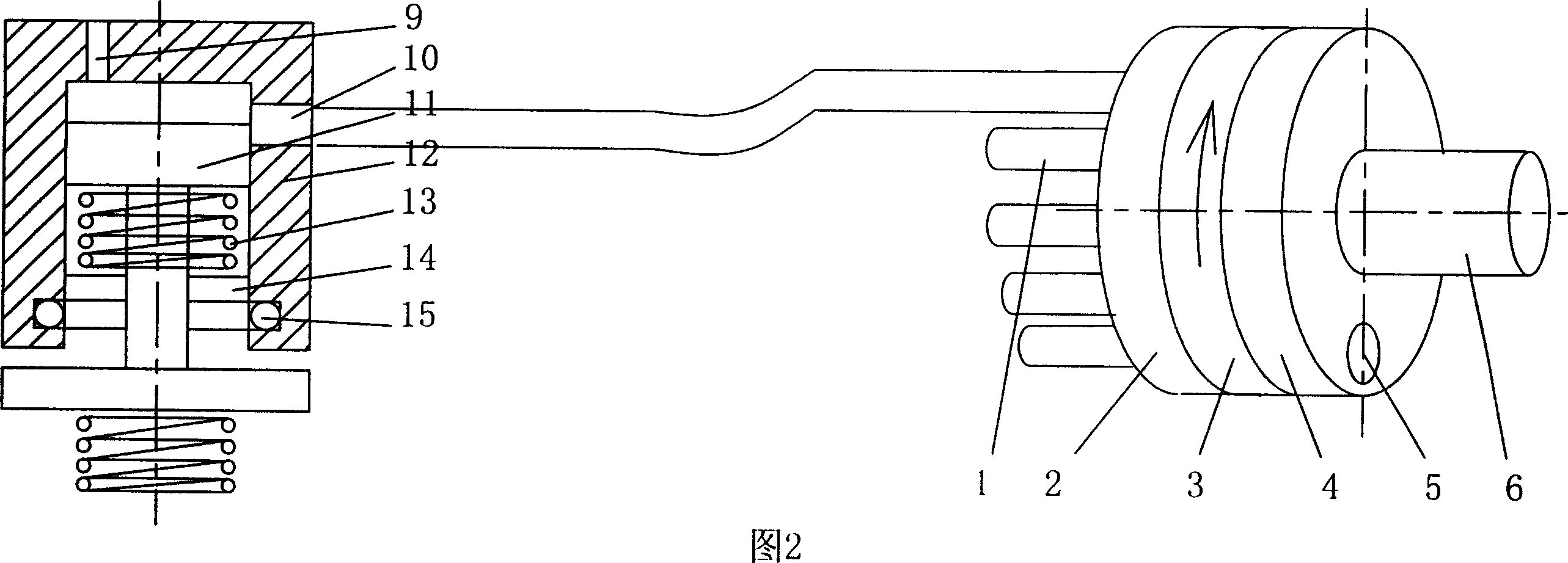

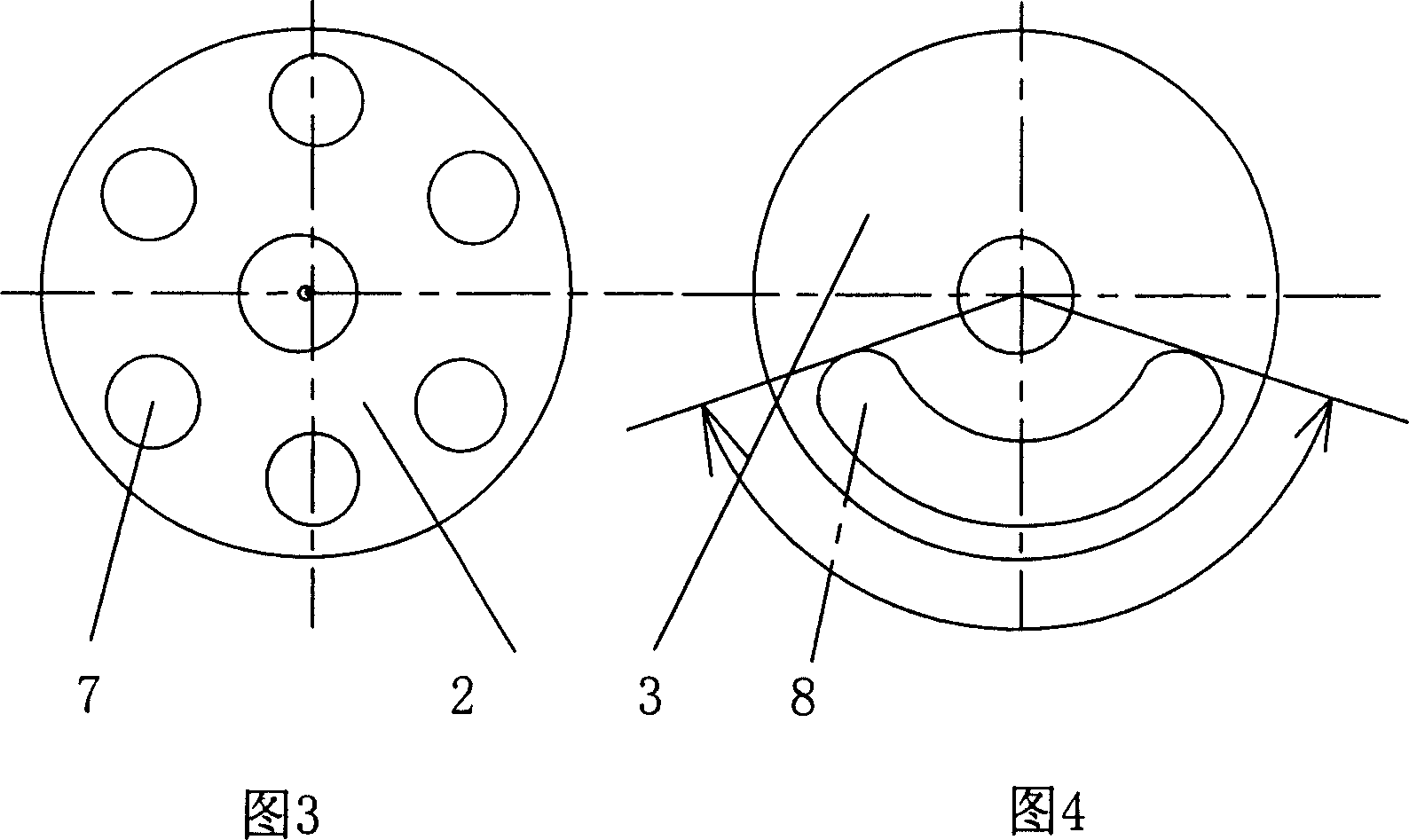

[0012] Shown in Fig. 2, 3, 4 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com