Process for preparing N-phenylamino acetonitrile

A technology of phenylaminoacetonitrile and production method, which is applied in chemical instruments and methods, preparation of carboxylic acid nitrile, preparation of organic compounds, etc., and can solve problems such as large amount of cooling capacity and steam, difficult treatment of cyanide-containing tail gas, and large investment in equipment , achieve the effect of good yield and quality, lower production cost and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

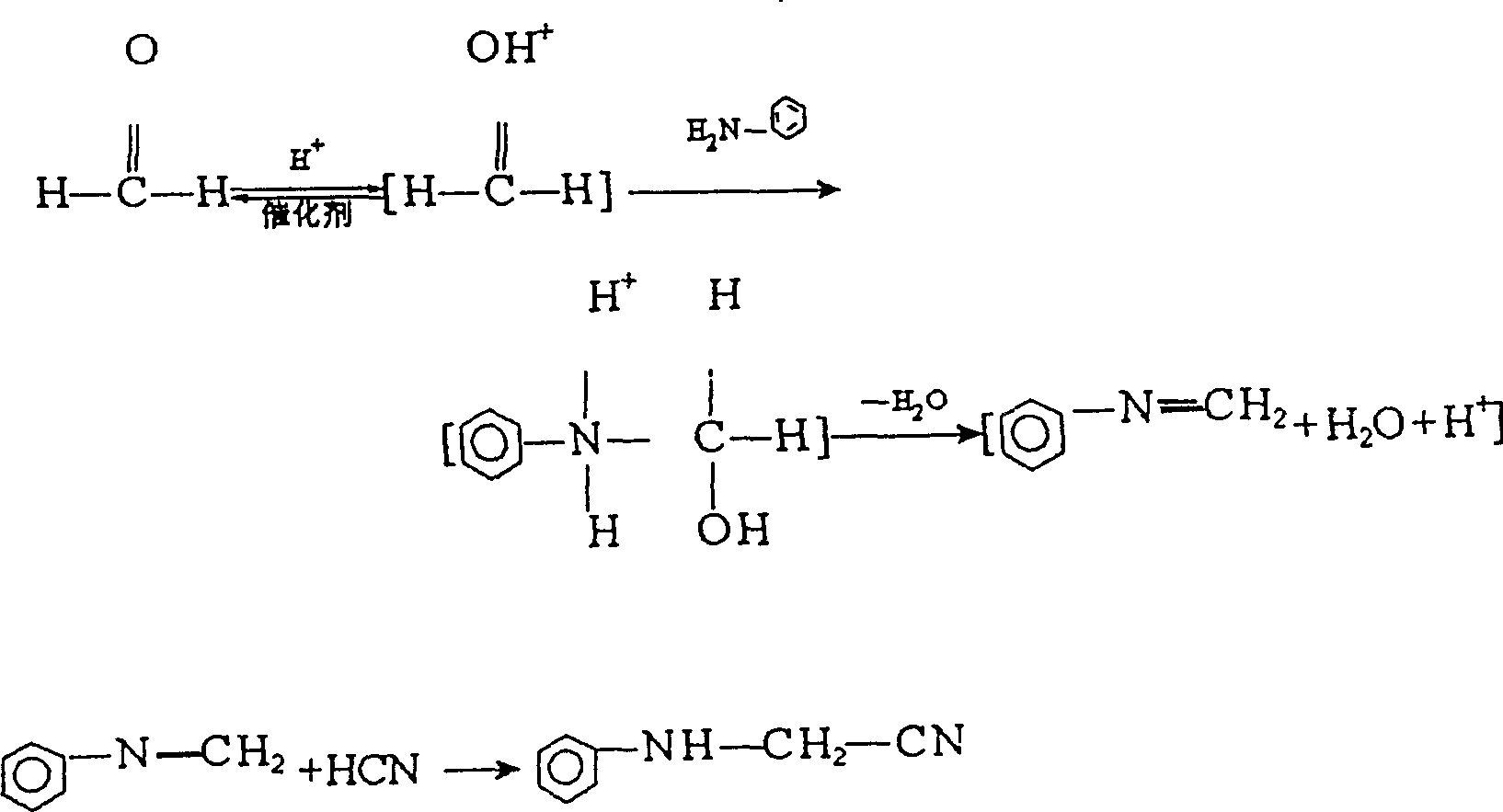

Method used

Image

Examples

Embodiment 1

[0025] Add 1500kg of aniline (industrial product) into the reaction kettle, under stirring, add 800kg of formaldehyde (industrial product) at 10-30°C, adjust the pH to 2-3 with sulfuric acid, and pass gas hydrocyanic acid (gas Hydrocyanic acid percentage concentration is 4~10%, all the other are air and inert gas), when formaldehyde is nearly consumed, then add 518kg formaldehyde, continue to pass into gas hydrocyanic acid simultaneously. At the end of the reaction, put the material into the extraction tank, extract it twice with water, and then put it into the crystallization tank. Add an appropriate amount of water to cool and stir to crystallize, and centrifuge to obtain 2049.2 kg of N-phenylaminoacetonitrile with a content of 98.5% and a yield of 95.2%.

[0026] Wastewater treatment: Combine the water phase, which contains a small amount of hydrocyanic acid, aniline and its derivatives, etc. Bubble air into the water phase to drive out most of the hydrocyanic acid and abs...

Embodiment 2

[0028] Add 1500kg of aniline into the reaction kettle, under stirring, add 1000kg of formaldehyde at 10-15°C, adjust the pH to 1.5-2.5 with phosphoric acid, and feed gaseous hydrocyanic acid at a constant speed at 85-90°C (the percentage concentration of gaseous hydrogencyanic acid is 10- 35%, the rest is air and inert gas), when the formaldehyde is nearly consumed, add 275kg formaldehyde, and continue to feed gaseous hydrocyanic acid at the same time. At the end of the reaction, put the material into the extraction tank, extract it twice with water, and then put it into the crystallization tank. Add an appropriate amount of water to cool and stir to crystallize, and centrifuge to obtain 2060.5 kg of N-phenylaminoacetonitrile with a content of 98.8% and a yield of 95.6%.

[0029] Waste water treatment is the same as embodiment 1.

Embodiment 3

[0031] Add 1500kg of aniline into the reaction kettle, under stirring, add 1250kg of formaldehyde at 50-60°C, adjust the pH to 1-3 with acetic acid, and feed gaseous hydrocyanic acid at a constant speed at 75-90°C (the percentage concentration of gaseous hydrocyanic acid is 35- 45%, the rest is air and inert gas), when the formaldehyde is nearly consumed, add 318kg formaldehyde, and continue to feed gaseous hydrocyanic acid simultaneously. At the end of the reaction, put the material into the extraction tank, extract it twice with water, and then put it into the crystallization tank. Add an appropriate amount of water to cool and stir to crystallize, and centrifuge to obtain 2075.3 kg of N-phenylaminoacetonitrile with a content of 99.6% and a yield of 96.5%.

[0032] Waste water treatment is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com