Paper machine cover

A technology for drying wire and paper machine, applied in paper machine, paper machine, wet end of paper machine, etc., can solve the problems of paper quality loss and falling, and achieve the effect of improving detachment and early detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

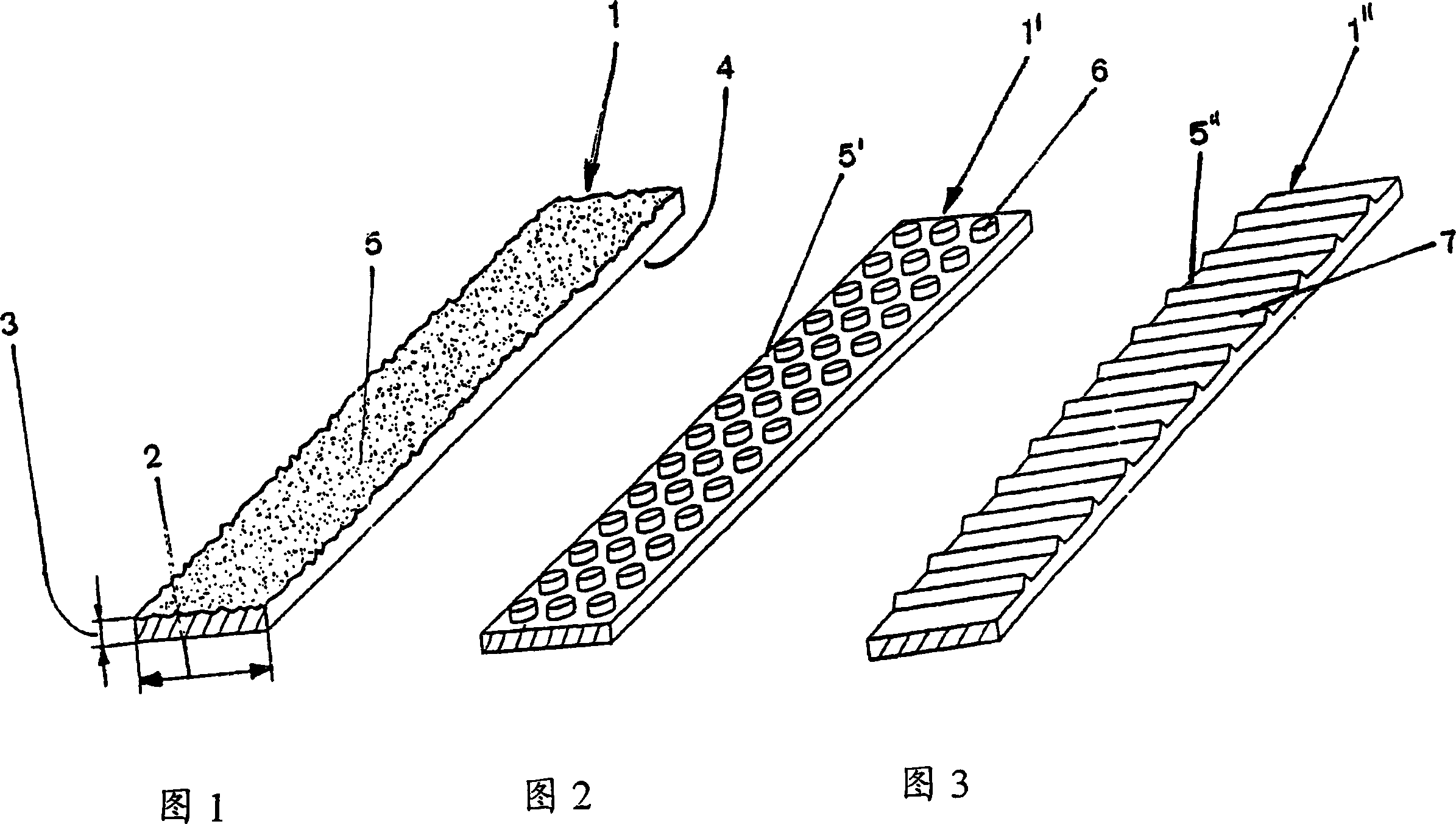

[0025] FIG. 1 is a perspective view of a section of flat strip 1 . The ratio of width 2 to thickness 3 of the flat strip is approximately 4:1. The flat belt 1 woven by the extrusion process is flat on one side (surface 4), while the web-contacting surface 5 formed when the belt 1 is formed into a woven drying wire has no texture. regular. This textured surface 5 has an average roughness of 5 μm to 100 μm. Such structures can be formed, for example, by embossing plastic that has not yet fully cured.

[0026] The flat strip 1' shown in FIG. 2 differs from that shown in FIG. 1 in that its surface 5' has a regular structure. The surface 5' has three rows of cylindrical elevations 6 extending parallel in the longitudinal direction. The elevations in the individual rows are equidistant from each other and likewise form rows of elevations in the transverse direction of the flat strip.

[0027] The elevations 6 can also be spherical or rounded in shape.

[0028] The surface 5 ″ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com