Pressure thermometering method during lyophilizing process

A pressure and freeze-drying technology, which is applied to thermometers, thermometers, measuring devices, etc. with physical/chemical changes, can solve problems such as being unable to represent, difficult to reflect temperature conditions, and unable to measure sublimation interface temperature in real time, and achieve rapid detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

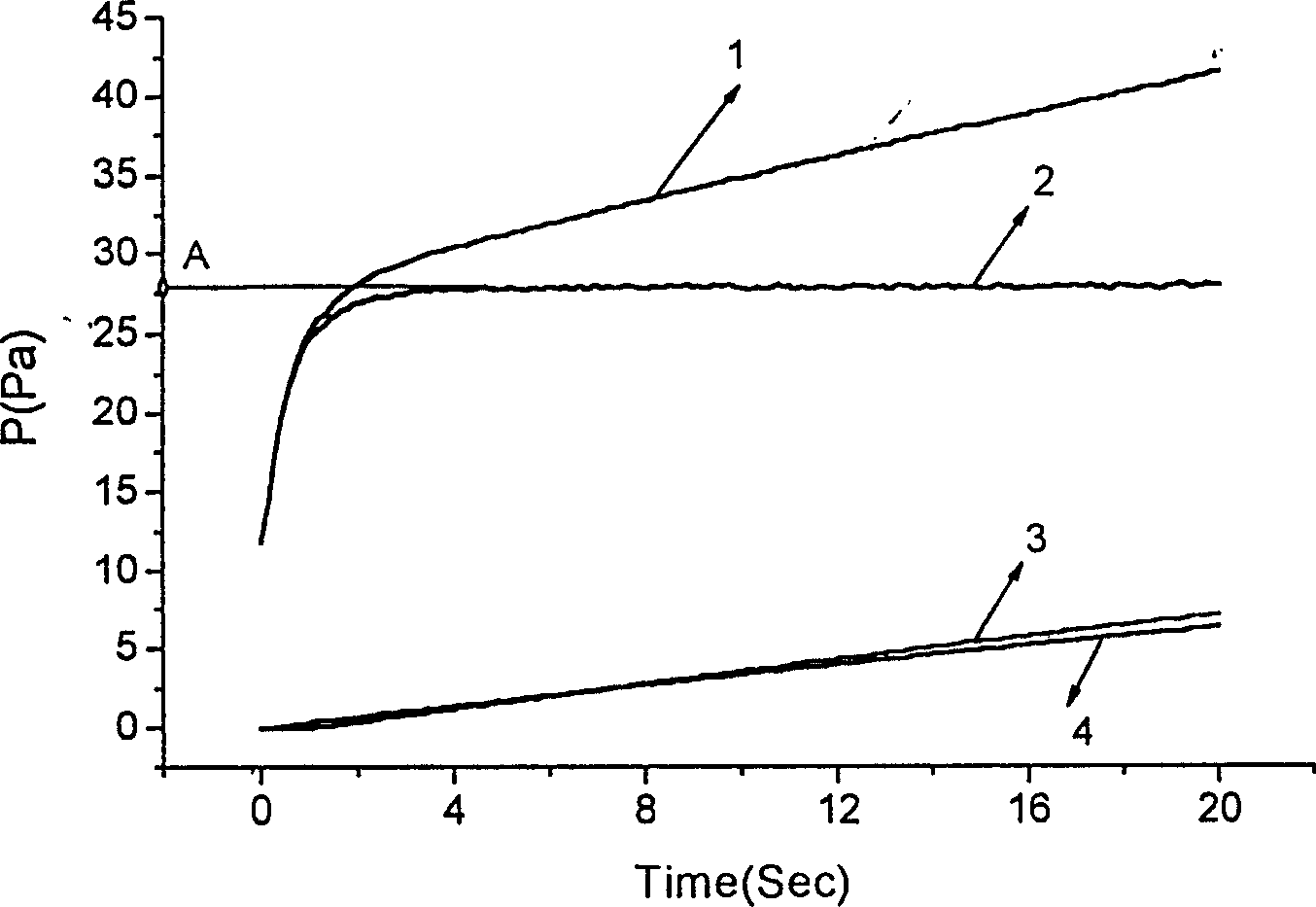

[0028] The basic principle and analysis method of pressure temperature measurement technology:

[0029] The pressure temperature measurement technology is based on the basic law that the temperature of ice crystals and its saturated vapor pressure are single-valued functions in an equilibrium state. During the sublimation drying process, the water vapor flow from the freeze-drying chamber to the cold trap is suddenly interrupted. A non-contact temperature measurement method to calculate the sublimation interface temperature based on the pressure rise in the room. figure 1 It shows the basic analysis method of pressure and temperature measurement technology. Line 1 in the figure is the pressure recovery curve of the freeze-drying chamber after the partition valve between the freeze-drying chamber and the cold trap is suddenly closed during the experiment. It can be imagined that after the middle septum valve is suddenly closed, if there is no leakage in the freeze-drying chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com