Method of fast extracting containers for realizing medium vacuum or microvac inside container and its combination machine set

A high-vacuum, high-vacuum technology, applied in the direction of machines/engines, liquid variable displacement machines, mechanical equipment, etc., to achieve the effects of portability, high efficiency, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

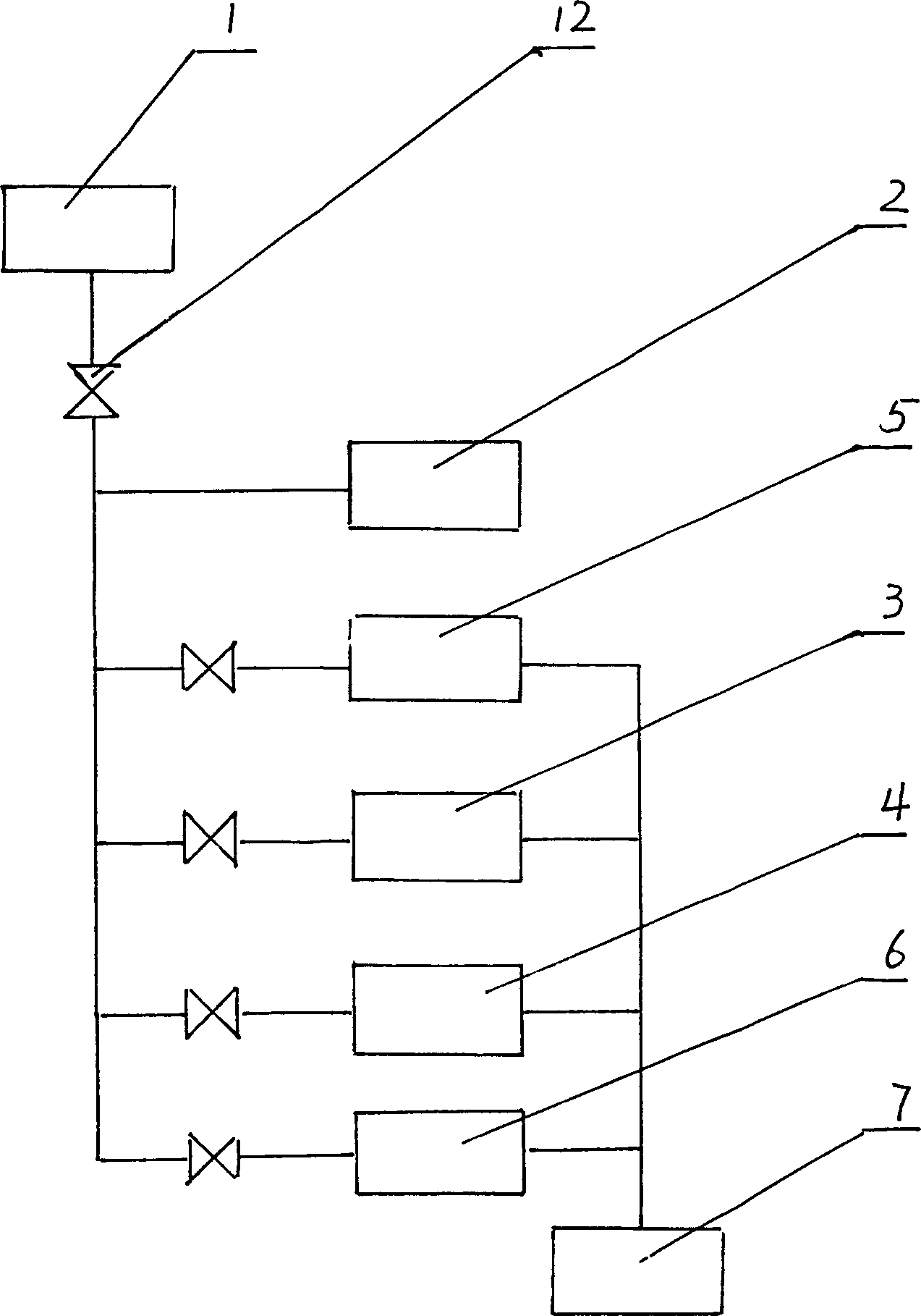

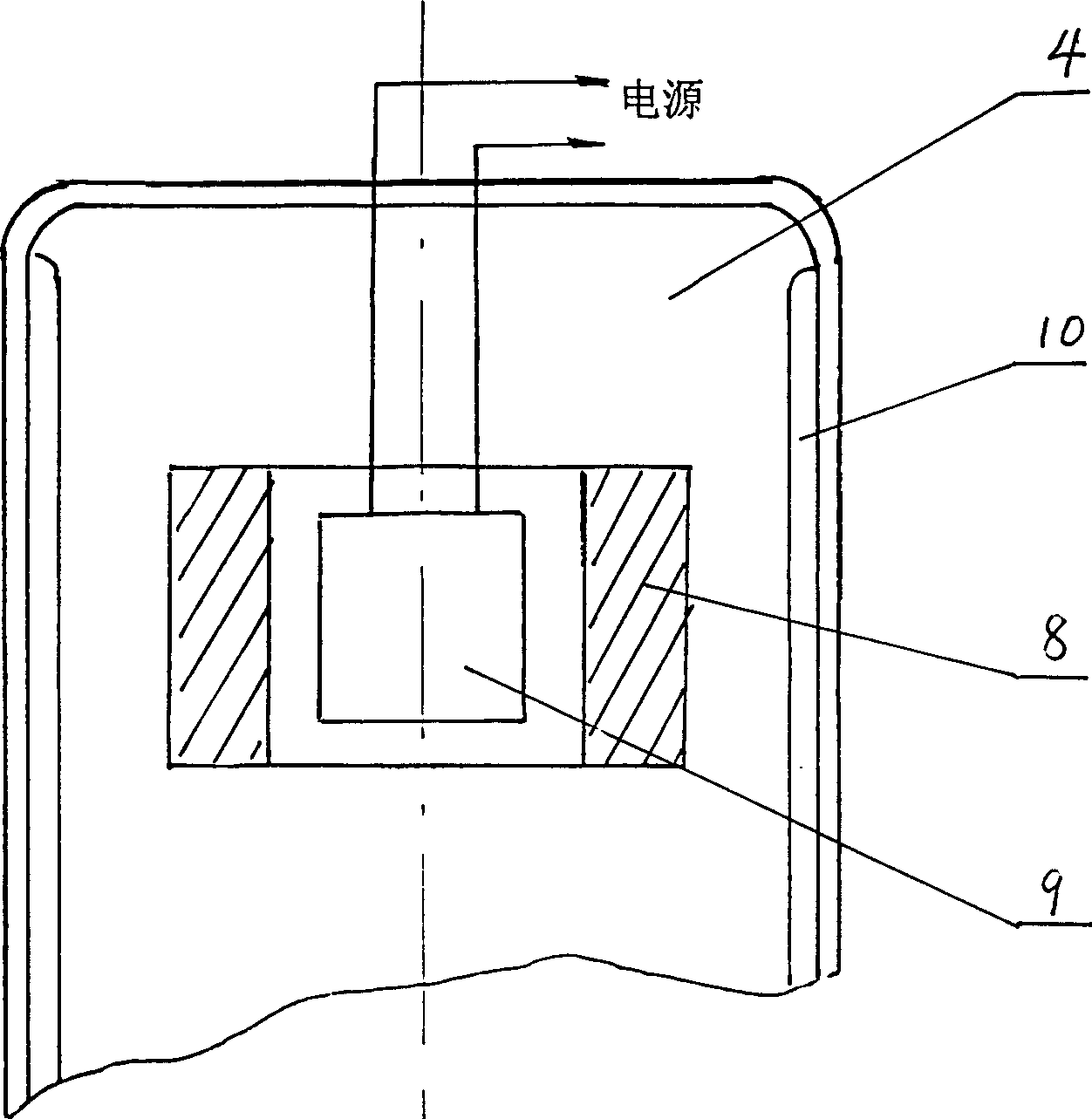

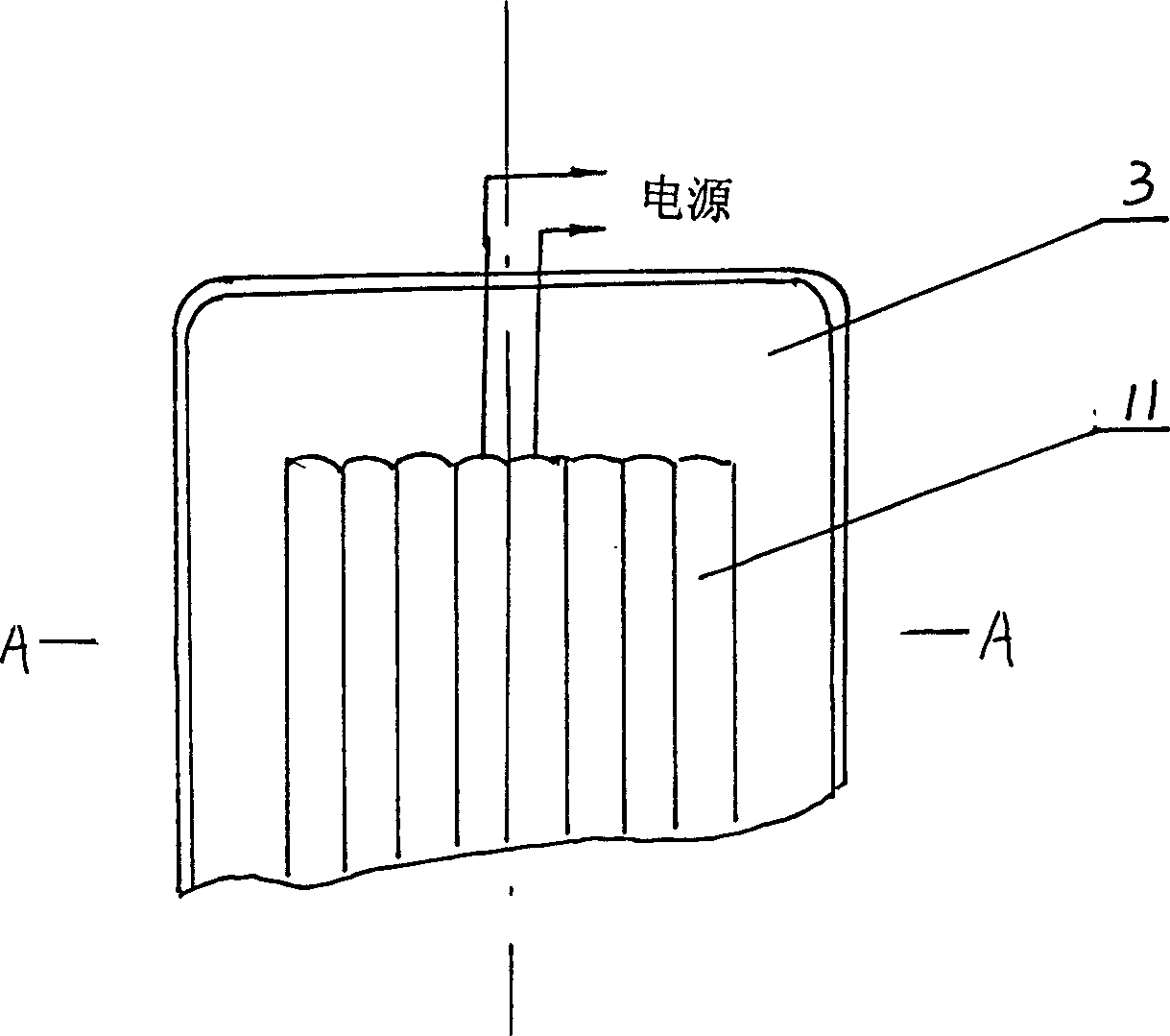

[0014] Depend on figure 1 It can be seen that the combined unit involved in the present invention includes: a vacuum degree measuring device 2, an auxiliary extraction suction chamber 3, a main extraction suction chamber 4, and also includes a degassing unit 5 and a vacuum pump 6; 12 is connected with the cavity interface 1 that needs to be vacuumed. During specific implementation, each independent unit can be installed on the same frame, and can also be assembled by pipelines. If each independent unit is installed on the same frame, the vacuum pump 6 can be selected as a small vacuum pump to provide energy for each independent unit. Power supply 7 can choose to use dry battery pack or accumulator pack.

[0015] The method for realizing the high vacuum degree in the cavity involved in the present invention is realized by the above-mentioned combination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com