Method for producing R-Fe-B permanent magnet, and lubricating agent and release agent for use in shaping same

A technology of molding and lubricants, applied in the direction of magnetic objects, metal processing equipment, magnetic materials, etc., can solve the problems of poor productivity, difficult to remove binders and molding strength, reduction of magnet performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Electrolytic iron with a purity of 99.9%, an iron-boron alloy containing 19.8% by weight of B, and Nd and Dy with a purity of 99.7% or higher are used as starting alloys. They are mixed at high frequency and then melted. They were cast into a mold with a water-cooled casting mold to obtain a billet with a composition of 14.5at%Nd-0.5at%Dy-78.8at%Fe-6.2at%B.

[0065] Then the above-mentioned billet was crushed by a hammer mill, and further crushed under the protection of a hydrogen atmosphere to obtain crushed powder with an average particle size of 40 μm. The obtained crushed powder passes at 6kG / mm 2 Under the condition of gas pressure and using inert gas (nitrogen), it is pulverized by a jet mill to obtain fine powder with an average particle diameter of 3 μm.

[0066] Methyl caproate lubricant (boiling point: 150°C, effective ingredient: 10%, Paresu Kagaku Co., Ltd., Magrupu PS-A-21) and methyl caprylate lubricant (boiling point: 150°C, effective ingredient: 10%, Paresu ...

Embodiment 2

[0074] Electrolytic iron with a purity of 99.9%, an iron-boron alloy containing 19.89% by weight of B, and Nd and Dy with a purity of 99.7% or higher are used as starting alloys. They are mixed and melted at high frequency, and then they are cast into a mold with a water-cooled casting mold to obtain a composition of 13.4at%Nd-2.6at%Dy-77.8at%Fe-6.2at%B Blank.

[0075] Then the above-mentioned billet was crushed by a hammer mill, and further dissociated under the protection of a hydrogen atmosphere to obtain crushed powder with an average particle size of 40 μm. The obtained crushed powder passes at 6kg / mm 2 Under the condition of gas pressure and using inert gas (nitrogen), it is pulverized by a jet mill to obtain fine powder with an average particle diameter of 3 μm.

[0076] As a depolymerized polymer, a copolymer with a molecular weight of 550 composed of isobutylene and n-butene, and a low-viscosity mineral oil with a dynamic viscosity of 5 mm at 40°C 2 / s pure paraffinic min...

Embodiment 3

[0095] Electrolytic iron with a purity of 99.9%, an iron-boron alloy containing 19.8% by weight of B, and Nd and Dy with a purity of 99.7% or higher are used as starting alloys. They are mixed and melted under high frequency, and then cast into a mold with a water-cooled casting mold to obtain a billet with a composition of 13.4at%Nd-2.6at%Dy-77.8at%Fe-6.2at%B.

[0096] Then the above-mentioned billet was crushed with a hammer mill, and further crushed under the protection of a hydrogen atmosphere to obtain crushed powder with an average particle size of 40 μm. The obtained crushed powder passes at 6kg / mm 2 Under the condition of gas pressure and using nitrogen as an inert gas, it is pulverized by a jet mill to obtain a fine powder with an average particle size of 3 μm.

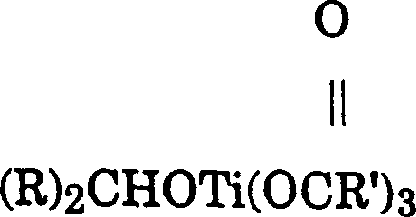

[0097] A mixture of various lubricants 1, 2 was added to the obtained fine R-Fe-B crushed powder and mixed, as shown in Table 10. Methyl caproate and methyl caprylate or Ti coupling agent (boiling point: 200°C or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com