External insulating layer of external wall of ultra high-rise building and its making method

A technology for building exterior walls and manufacturing methods, applied in the directions of thermal insulation, construction, building components, etc., can solve problems such as the height cannot be developed to a high level, the finish can only be painted with paint, and the joints are prone to cracks, etc., and achieves good energy-saving effect. The effect of good moisture resistance or water resistance and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

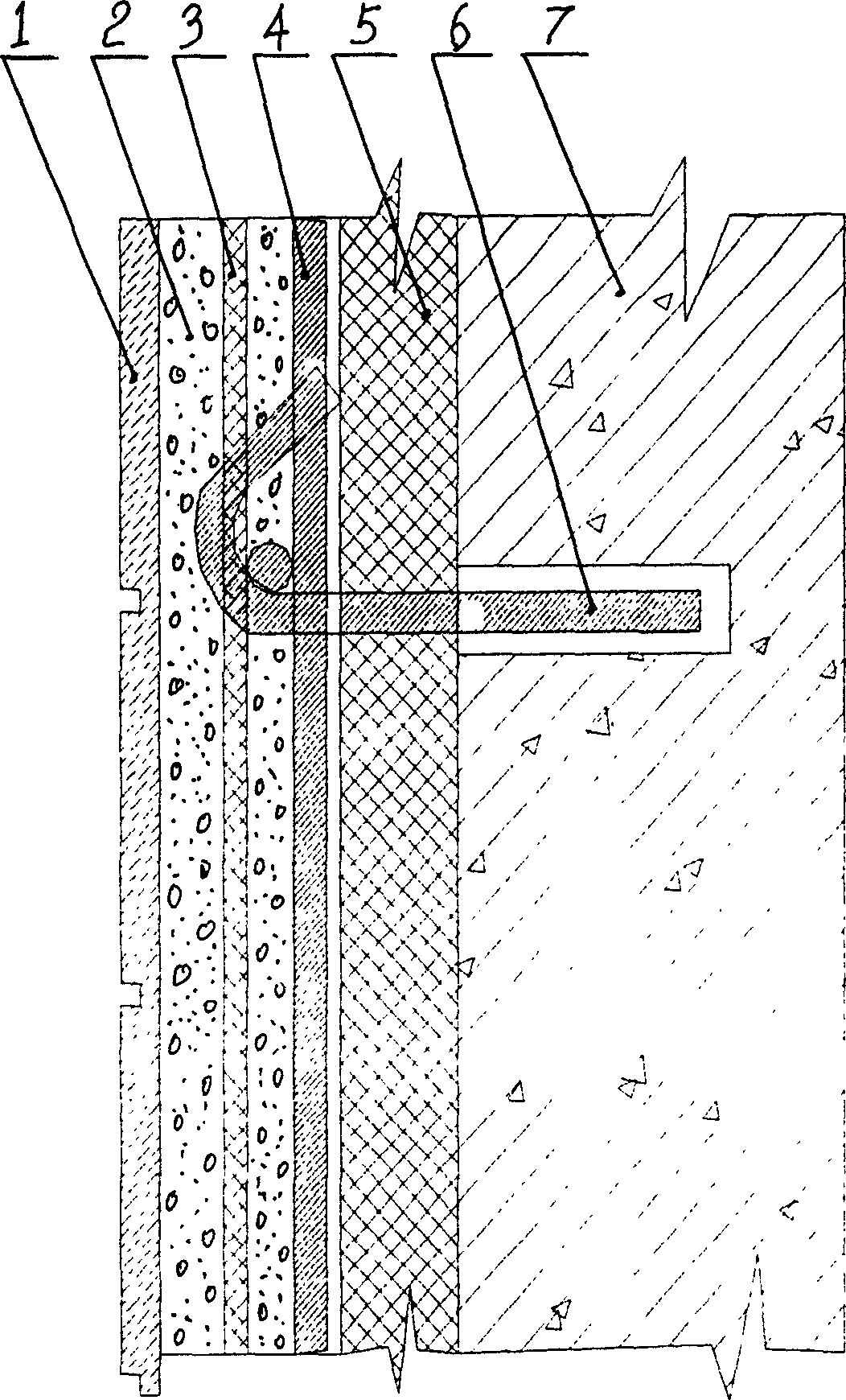

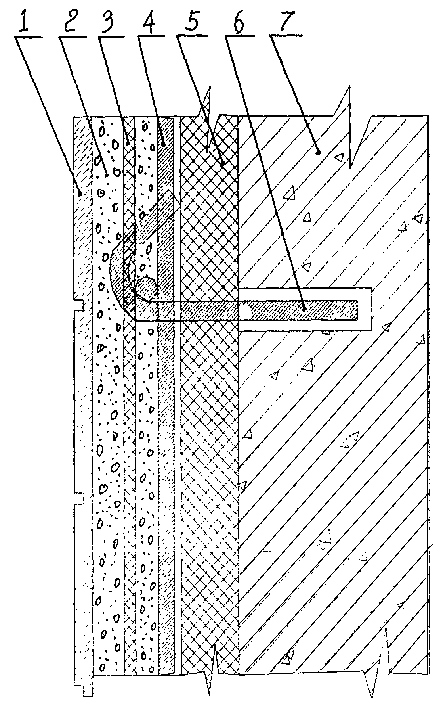

[0036] exist figure 1 Among them, the outer thermal insulation layer of the super high-rise building exterior wall of the present embodiment is made of decorative brick 1, concrete layer 2, steel mesh 3, steel mesh 4, polystyrene thermal insulation board 5, planting steel bar 6, polystyrene thermal insulation board 5 is An embodiment of the insulation board, the facing brick 1 is an embodiment of the facing layer. Make a hole on the concrete exterior wall 7 and insert the steel bar 6. The distance between a plant steel bar 6 on the concrete exterior wall 7 and an adjacent plant steel bar 6 in this embodiment is 400mm and is evenly distributed. On the concrete exterior wall 7, Yin and Yang The planting steel bars 6 at the corners are 60mm apart from the edge, and the planting steel bars 6 at the four sides of the window opening on the concrete exterior wall 7 are 60mm apart from the four sides of the window opening. A polystyrene insulation board 5 is installed on the external...

Embodiment 2

[0055] In the present embodiment, the distance between a planted steel bar 6 and an adjacent planted steel bar 6 on the concrete exterior wall 7 is 350 mm, the mesh of the steel mesh 4 is a square with a side length of 150 mm, and the mesh of the steel mesh 3 is a side with a length of The square of 20mm, other components and the coupling relationship of components are the same as in embodiment 1, and its manufacturing method is the same as in embodiment 1.

Embodiment 3

[0057] In this embodiment, the distance between a planted steel bar 6 and an adjacent planted steel bar 6 on the concrete exterior wall 7 is 450 mm, the mesh of the steel mesh 4 is a square with a side length of 250 mm, and the mesh of the steel mesh 3 is a side with a length of 250 mm. The square of 30mm, other components and the coupling relationship of components are the same as in embodiment 1, and its manufacturing method is the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com