Cathode-ray tube

A technology of cathode ray tube and shadow mask, applied in the frame field of color cathode ray tube, can solve the problems of color impurity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

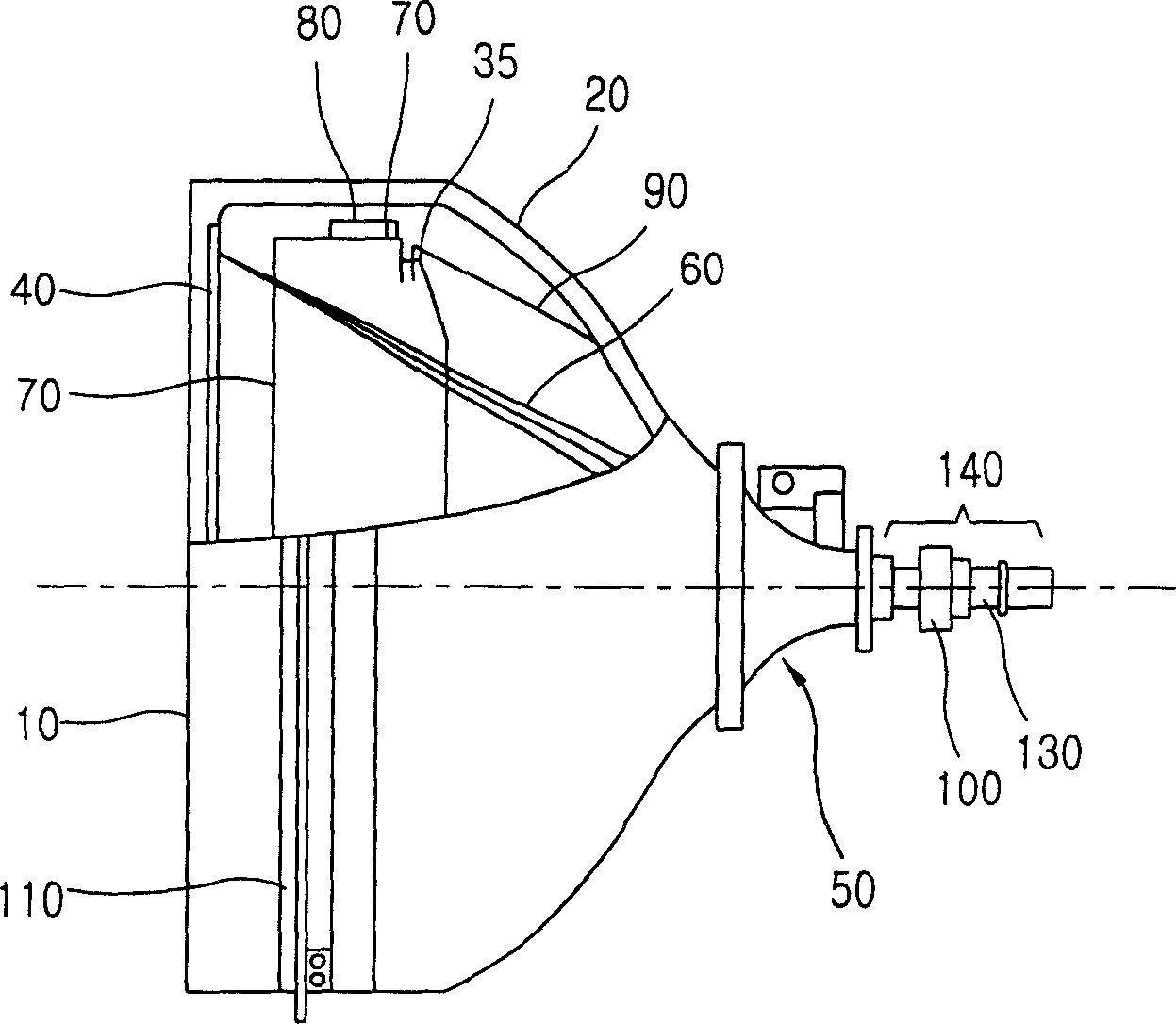

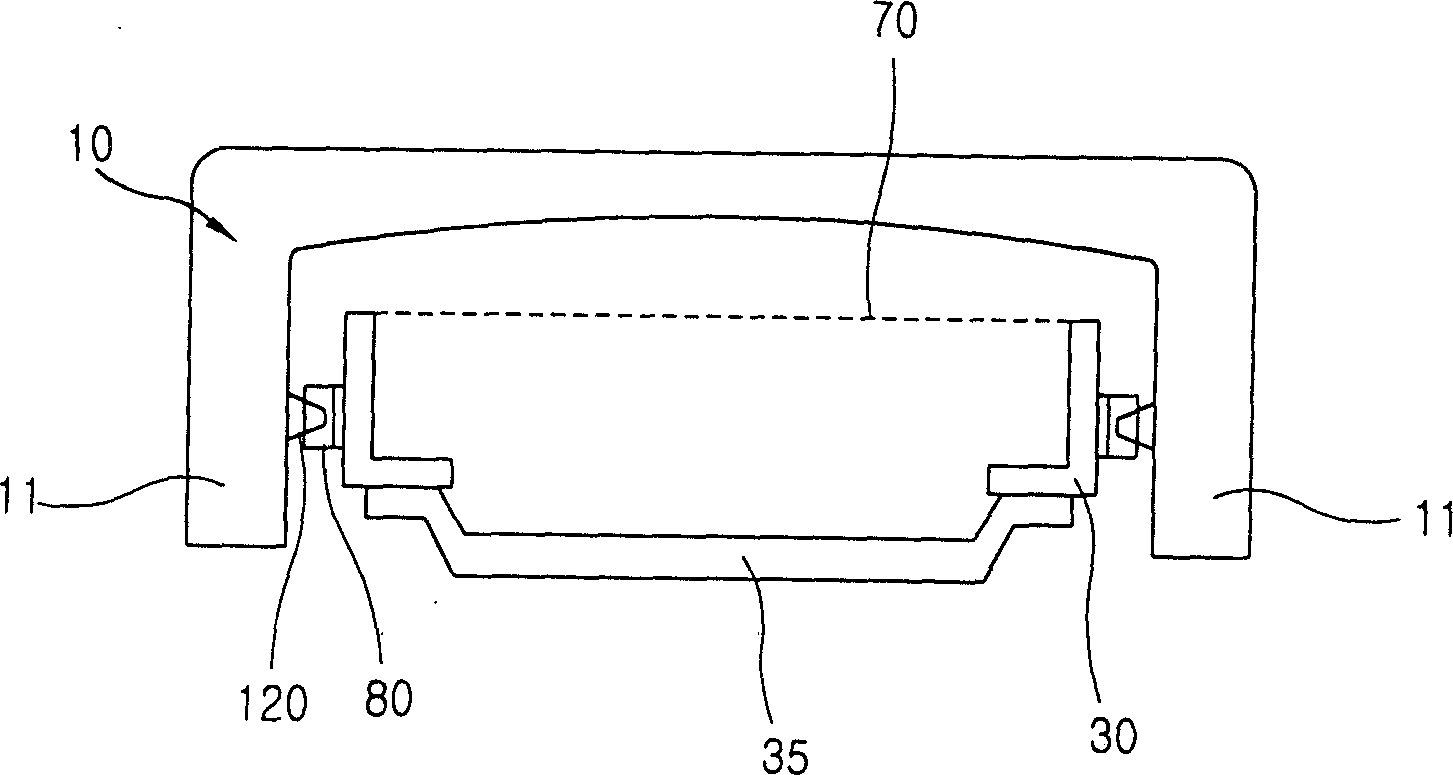

[0052] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0053] Those parts that are the same as those of the conventional art will be assigned the same reference numerals, and explanations about them will be omitted.

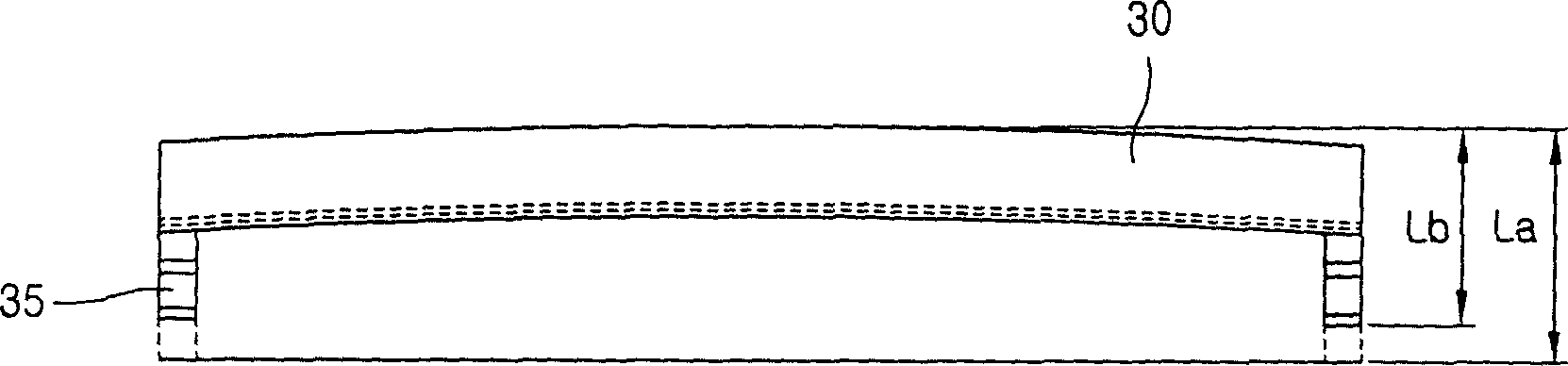

[0054] The present invention relates to a CRT capable of increasing the amount of compression without additional heat treatment for increasing the strength of the frame material, utilizing the frame by setting the range of the deflection length before and after mounting the shadow mask to the shadow mask assembly The material's own elasticity applies a tension to the mask, thereby increasing the tensor applied to the mask.

[0055] According to the present invention Figure 3A , 3B and 3C, before the shadow mask 70 is installed into the shadow mask assembly, the minimum distance between the extension plane of the upper surface of the main frame 30 and the extension plane of the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com