Solid luminous device packaged radiating member and its making method

A light-emitting device and manufacturing method technology, applied in semiconductor/solid-state device components, electric solid-state devices, cooling/ventilation/heating transformation, etc., can solve the problems of optical design heat dissipation, high labor-intensive, bulky packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

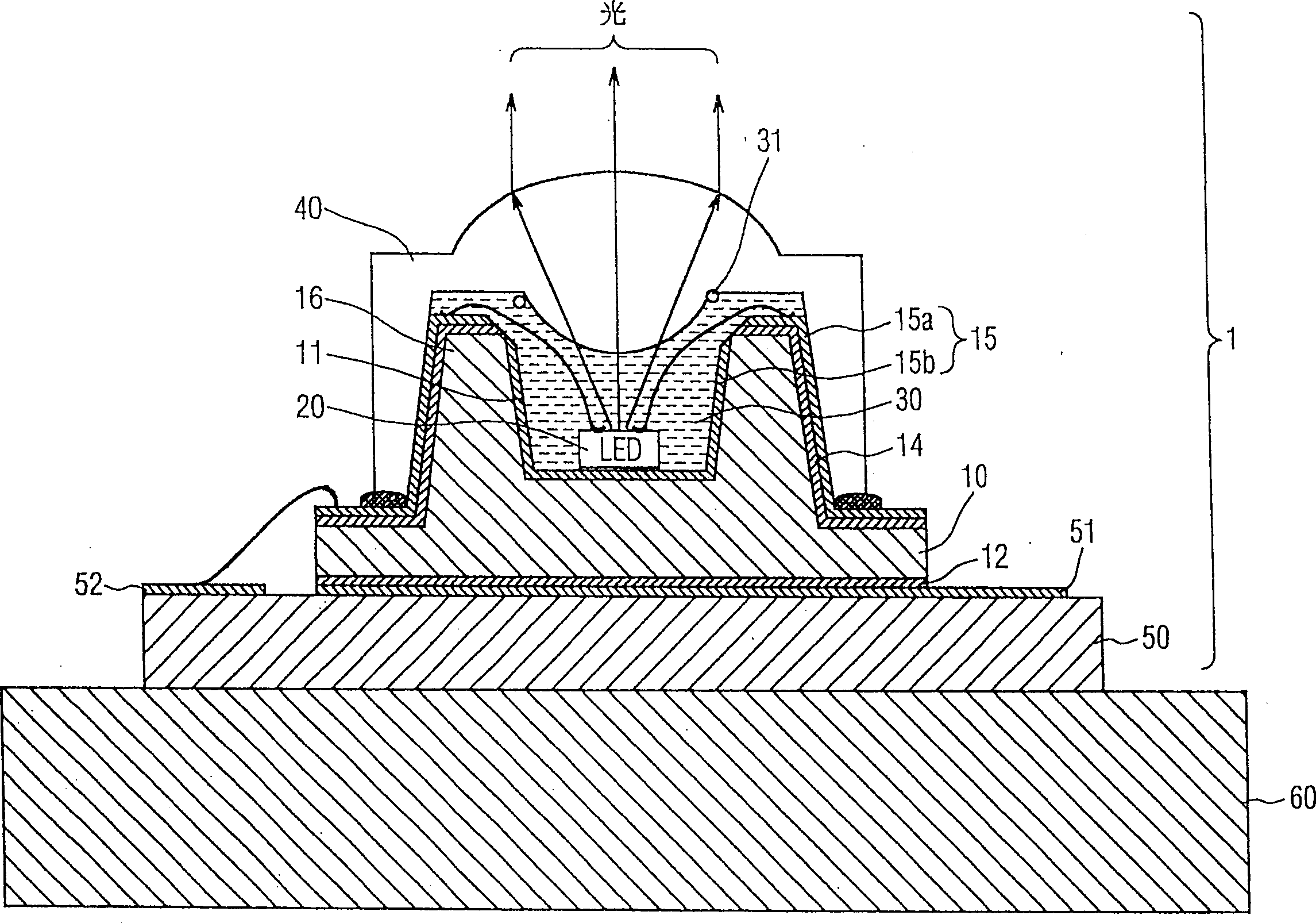

[0023] In the following description of the preferred embodiments, reference is made to figure 1 , illustrating a solid-state light emitting device package 1 with a heat dissipation member according to a first embodiment of the present invention.

[0024] The solid state light emitting device package 1 includes a metal substrate 10 , at least one LED chip 20 , an electrically insulating cooling liquid 30 , a transparent cover 40 , and a printed circuit board (PCB) 50 .

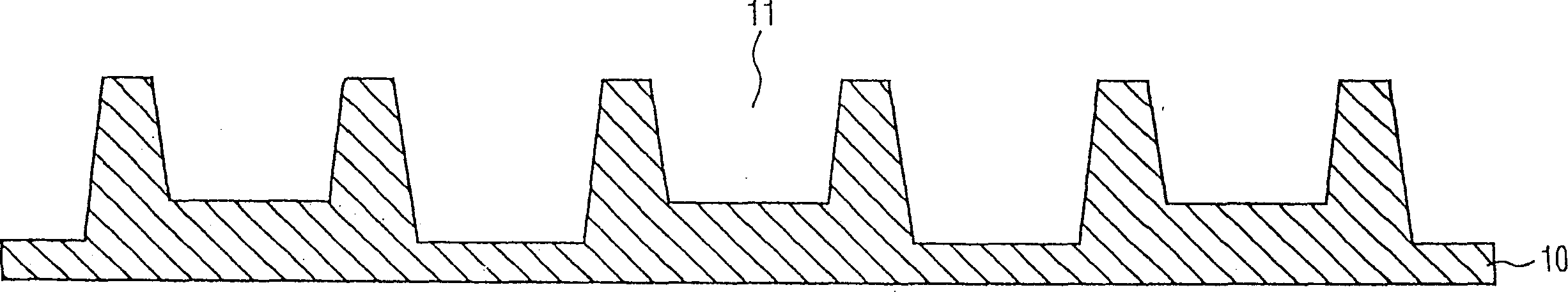

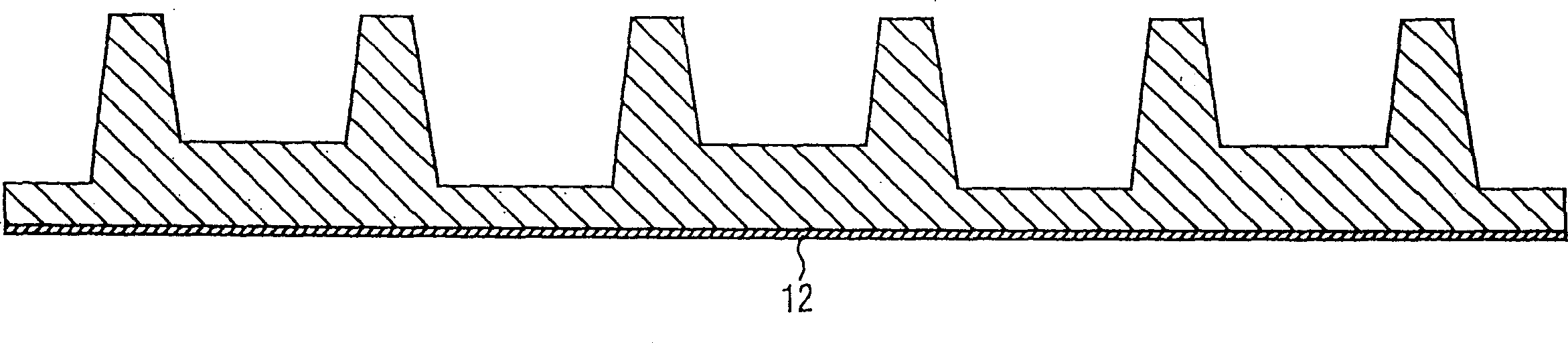

[0025] The metal substrate 10, which is preferably made of a material having excellent thermal conductivity such as aluminum, copper, etc., is formed with an upstanding wall portion 16 on one surface thereof, so that the surface of the metal substrate 10 will be formed as a cup-shaped portion 11. . Moreover, on the other surface of the metal substrate 10 opposite to the cup-shaped portion 11, there is a metal solder layer 12 such as copper, silver, or gold for connecting to the electrode 51 of the PCB 50, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com