Microwave electrodeless discharging ultra violet ray disinfectant microwave oven

A technology of ultraviolet light and microwave oven, which is used in household stoves/stoves, electric heating fuels, household heating, etc., which can solve the problems of difficult cleaning, short life, and inability to withstand microwave ovens for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

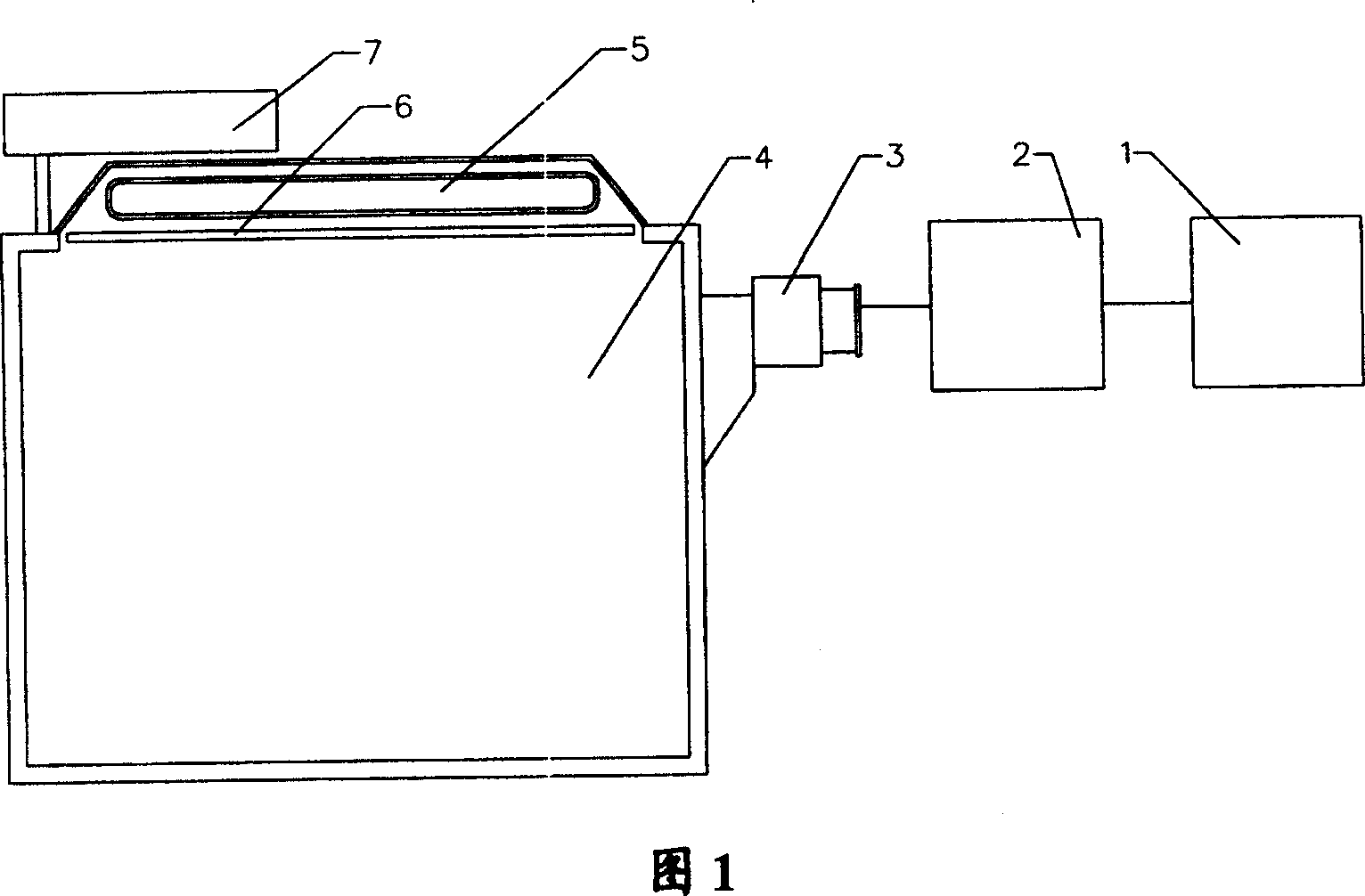

Embodiment 1

[0053] Open a closed groove 16 with a length of 200 mm, a width of 70 mm, and a depth of 40 mm in the center of the top surface of the inner wall of the cavity 4 of the 850W microwave oven, and install a 15 mm in diameter, 160 mm in length, electrodeless, filament-free, and power-free, which can emit 254nm ultraviolet light and prevent 185nm and 320-400nm ultraviolet light from escaping linear microwave electrodeless discharge ultraviolet lamp tube 5, the material of the lamp tube 5 shell 13 is high-purity quartz plus a little titanium metal, and the inner cavity 14 of the lamp tube 5 is filled Appropriate amount of neon gas and solid mercury, the mass of mercury is 500mg. A stainless steel shielding sheet 6 with a length of 205mm, a width of 75mm, and a thickness of 0.5mm is arranged below the closed groove 16 and is close to the closed groove 16. The shielding sheet 6 can completely cover the closed groove 16. The end of the shielding sheet 6 has a support rod to be connecte...

Embodiment 2

[0060] On the upper part of the left and right inner walls of the cavity 4 of the 1000W microwave oven, reserve a pair of parallel, equal height, and symmetrical brackets 18, and install a light-touch switch at the end of the bracket 18, and the light-touch switch is connected to the power attenuator 2 .

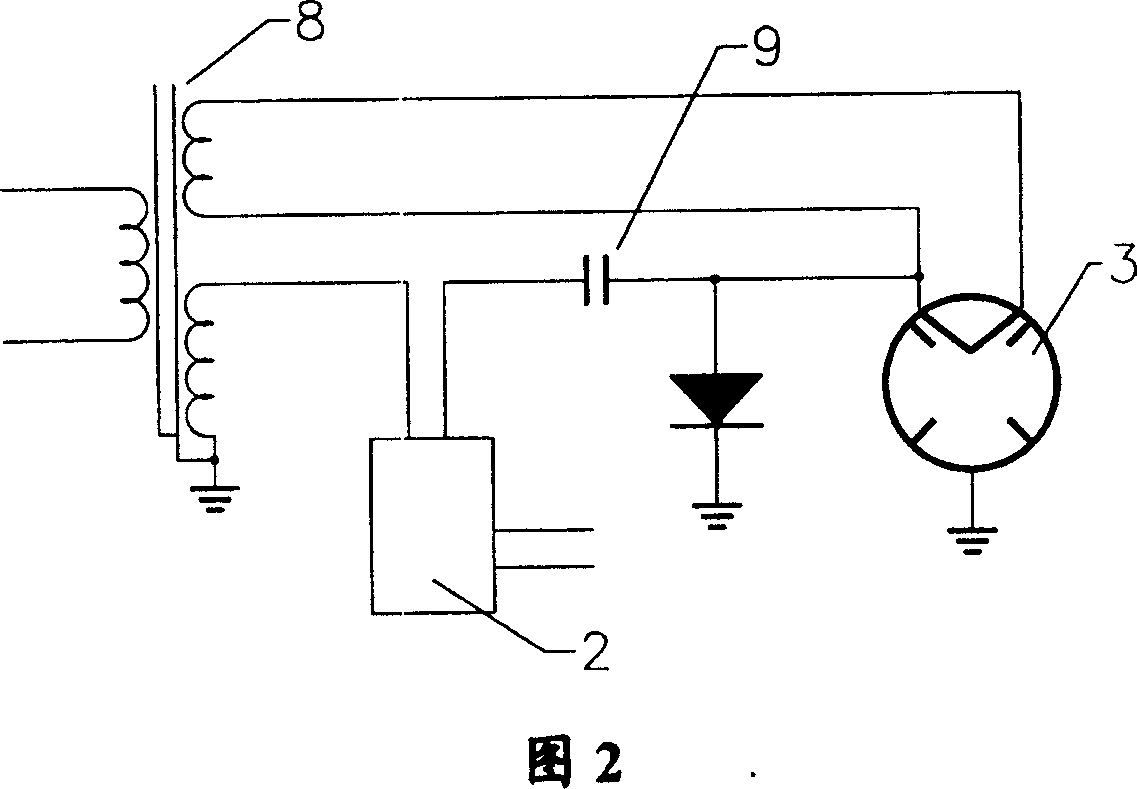

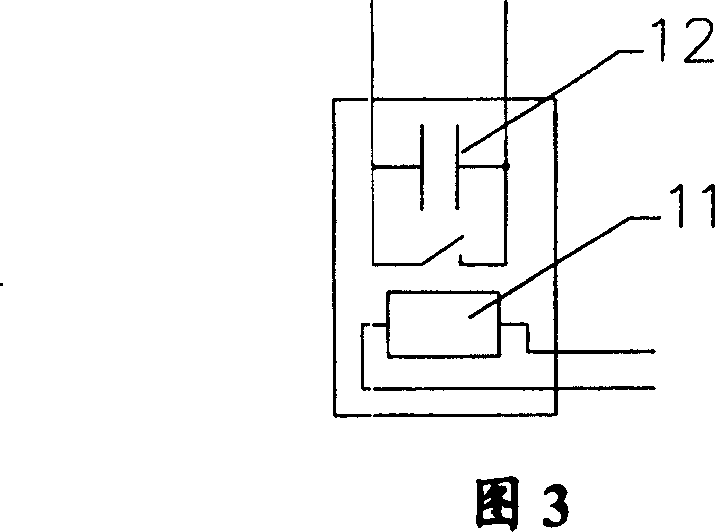

[0061] The power attenuator 2 is arranged in the electric control room 15 of the microwave oven. The power attenuator 2 is composed of a high-voltage relay 11 and a high-voltage capacitor 12 . The on-off switch of the high-voltage relay 11 is connected in parallel with the high-voltage capacitor 12 . The high voltage relay 11 of the power attenuator 2 is connected with the high voltage power supply 1 of the microwave oven. One end of the high-voltage capacitor 12 of the power attenuator 2 is connected to one winding of the high-voltage transformer 8 of the microwave oven, and the other end is connected to the magnetron 3 through the high-voltage capacitor 9 of the microwave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com