Magnetic suspension motor for electric vehicle

An electric vehicle and maglev technology, applied in electric vehicles, vehicle parts, motors, etc., can solve the problems of accelerating battery power consumption, short vehicle continuous driving time, increasing vehicle weight burden, etc., to achieve less energy consumption and structural Scientific and reasonable design, ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

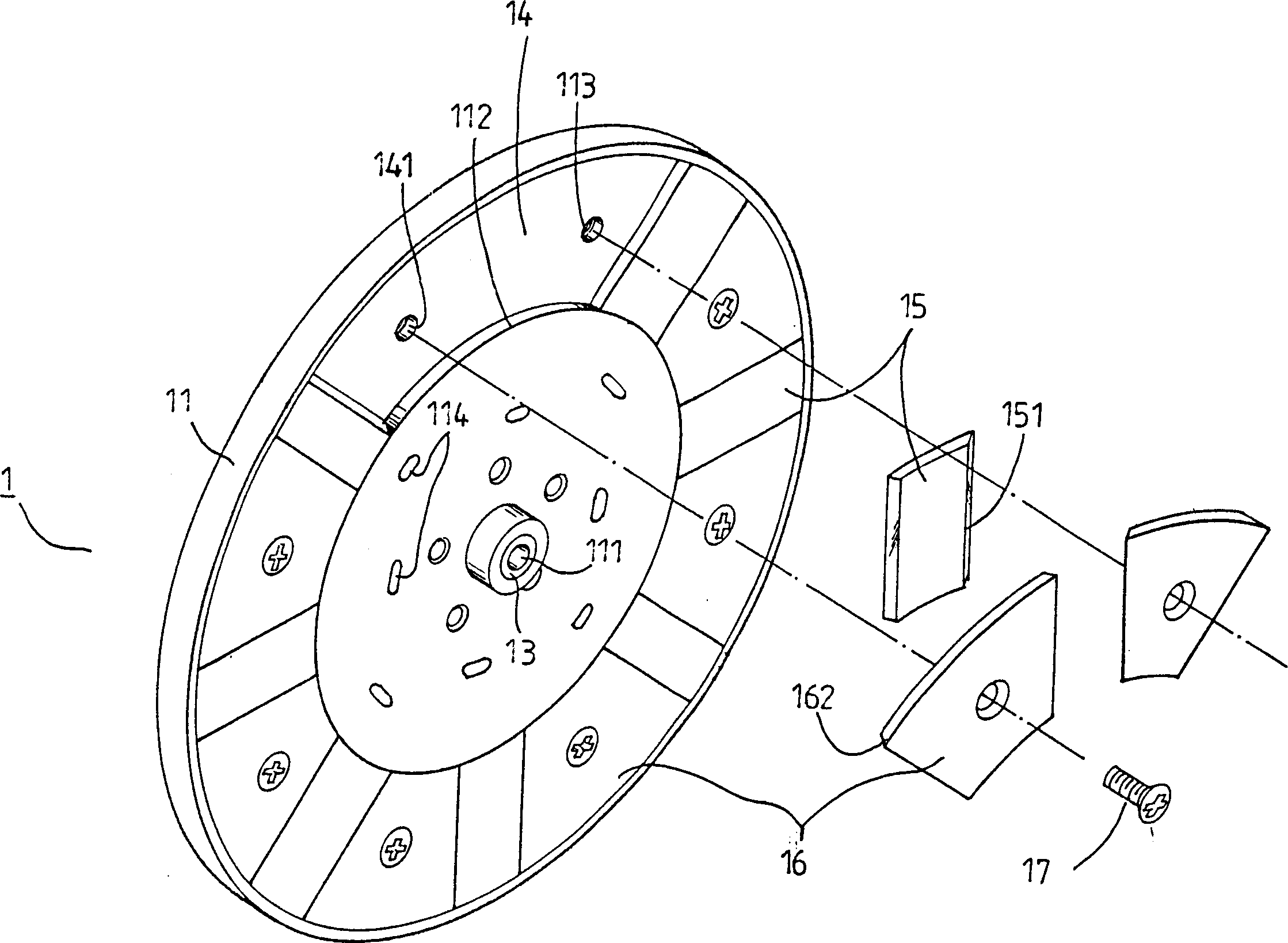

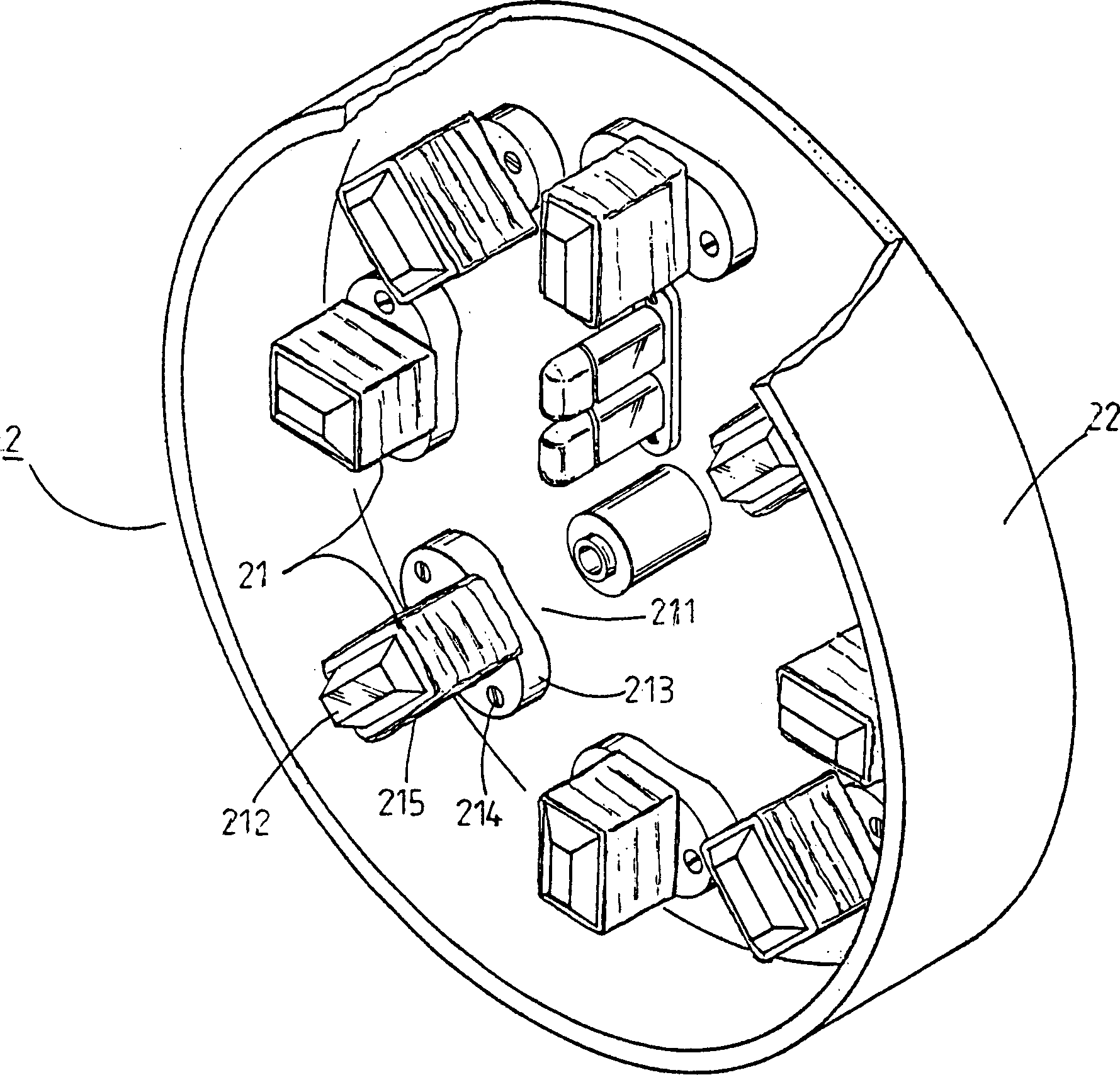

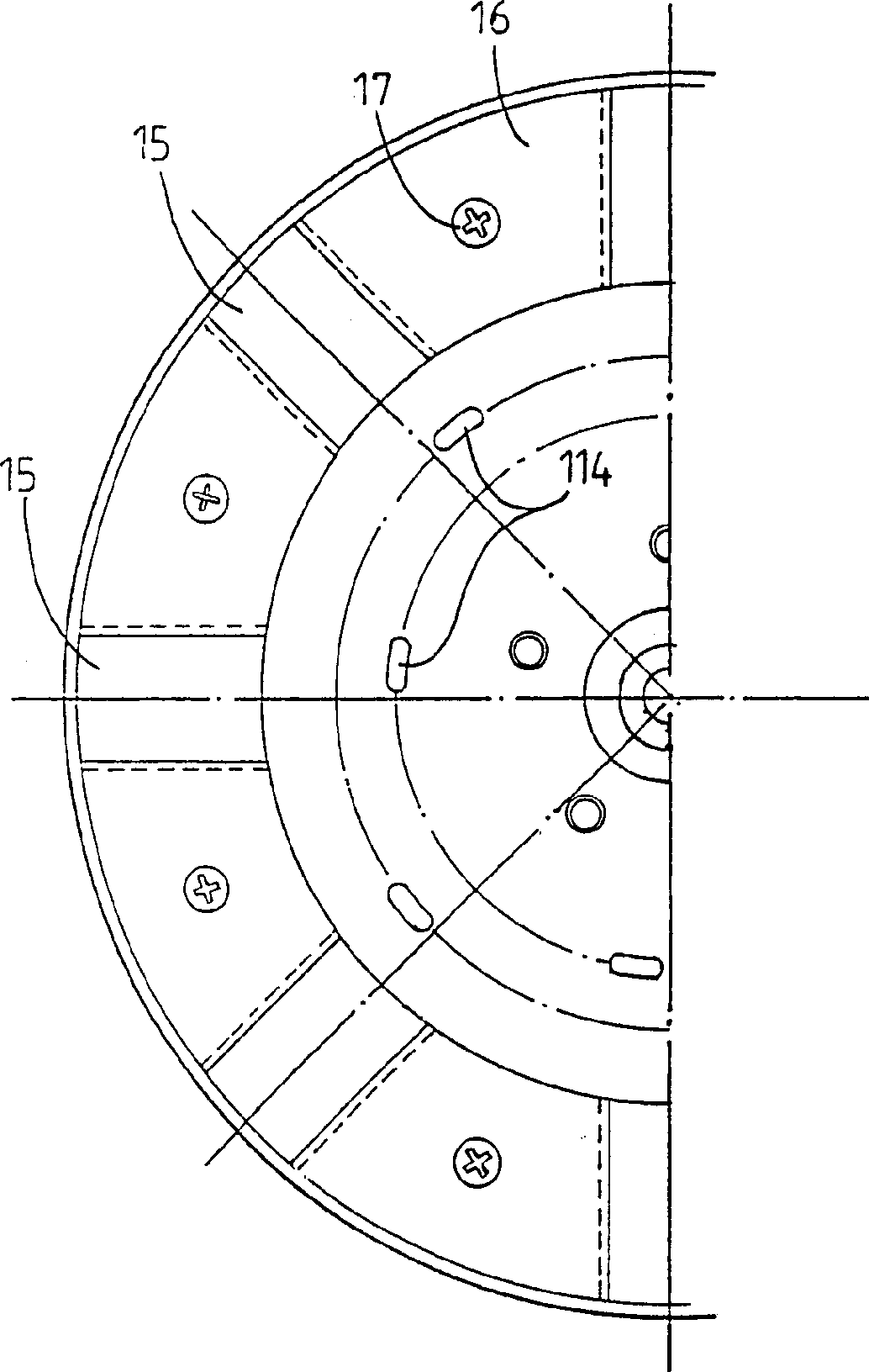

[0040] A magnetic levitation motor of an electric vehicle is provided with a rotor assembly 1, an electromagnetic pole set 2 and a loop control unit 3, wherein, refer to figure 1 , Figure 3a , Figure 3bAs shown, the rotor assembly 1 is a circular disc with more than one set of permanent magnets with corresponding angles. The perforated hole 111 is passed through, and a bearing 13 is provided on both sides of the perforated hole 111. The turntable 11 is chiseled with a circle of concave ring grooves 112 on the surface of the outer ring. The ring groove 112 has an appropriate depth and is provided with a magnetically conductive plate 14 The position of the corresponding angle of the magnetic guide plate 14 is provided with several perforations 141, and the perforations 141 become blind holes until the turntable body, and the blind hole part is provided with internal threads 113; the magnetic guide plate 14 is laid with more than one set of N poles and S poles The permanent m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com