Improved planed thin bamboo and productive method thereof

A production method and slicing technology, which are applied in the manufacture of thin wood chips, wood processing appliances, manufacturing tools, etc., can solve the problems of tearing, easy gnawing, and large thickness deviation of thin bamboo chips, so as to achieve uniform thickness and easy planing. Cut and wear less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1. The production method of this example sliced thin bamboo chip is:

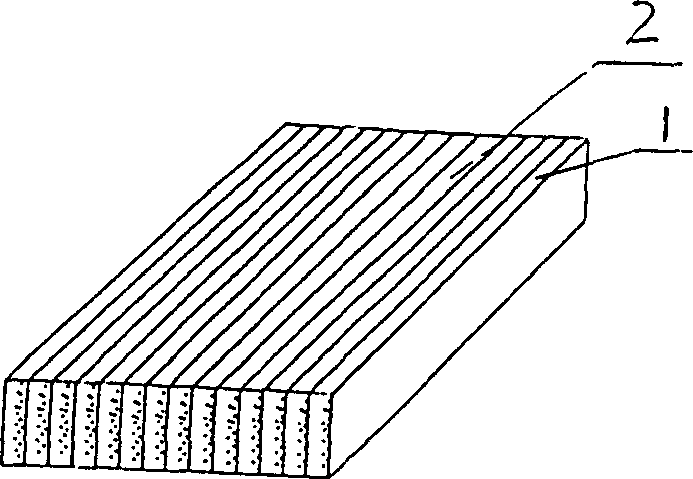

[0020] 1) Make bamboo blocks. First select the pretreated natural color bamboo piece 1, which is 1950mm long, 17.5mm wide, and 6mm thick; figure 1 .

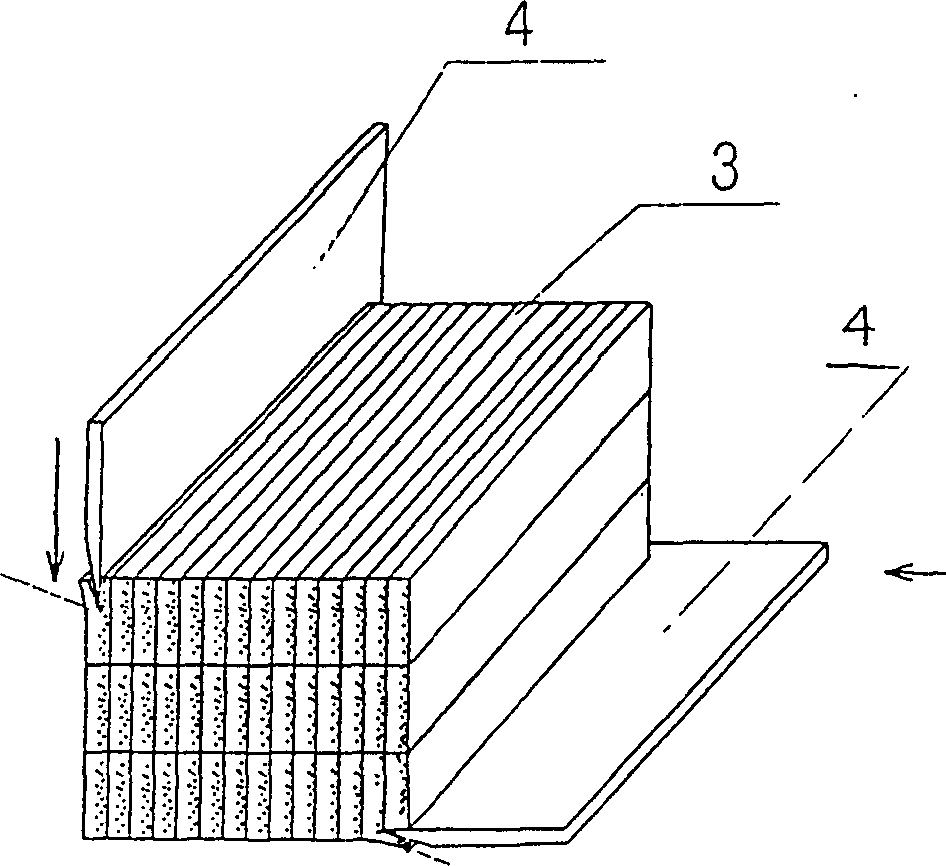

[0021] 2) Bamboo making method: Put the bamboo block 2 into a sealed container, soak it in water under pressure until the water content is about 55%; blow dry or dry it until there is no obvious water mark, and the surface appears light white, then apply glue and pressurize the layer Accumulate into bamboo square 3.

[0022] 3) Soften the bamboo square: immerse the bamboo square 3 in warm water at about 60°C for 36 hours to soften.

[0023] 4) Slicing: see figure 2 , adjust the angle α between the blade of planing cutter 4 and the direction of bamboo fiber to be 0° (i.e. parallel) to carry out planing, get wet planing thin bamboo slices, get width after drying and be 160mm, thickness is the natural color thin bamboo slices of 0.6mm 5. ...

Embodiment 2

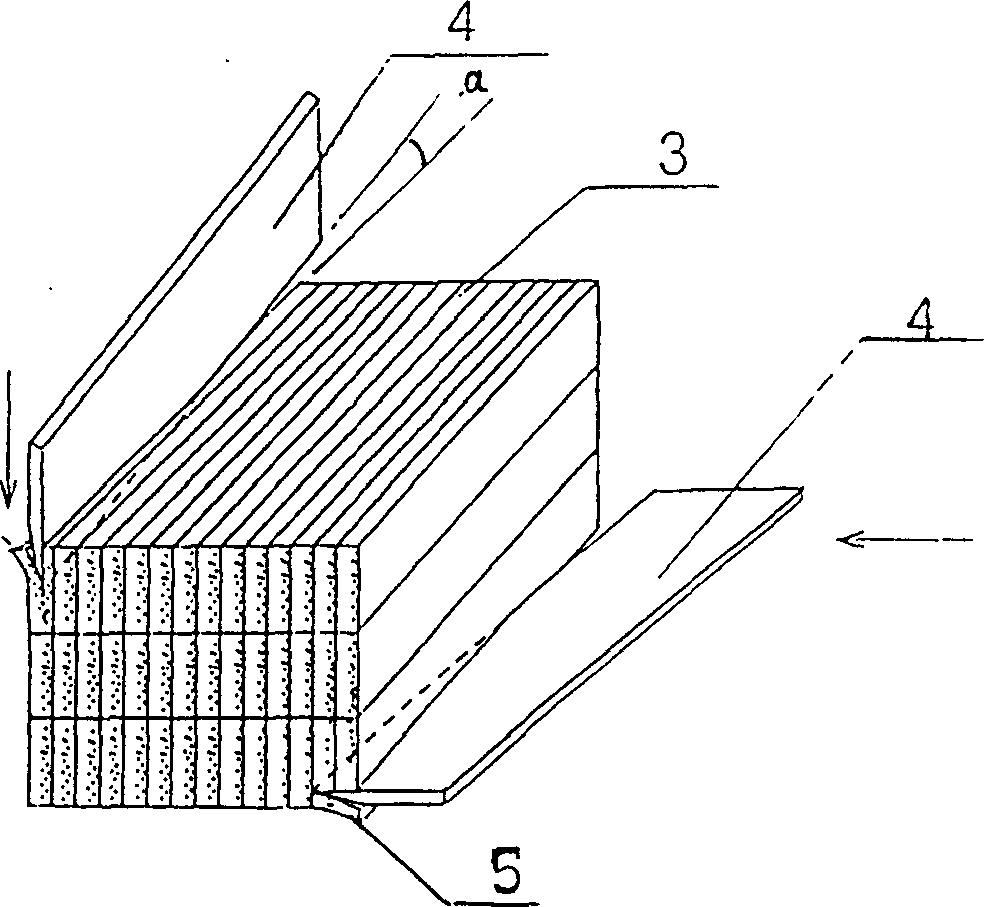

[0024] Example 2. The production method of sliced thin bamboo slices in this example is different from Example 1: choose pretreated carbonized bamboo slices; soak in water under pressure until the moisture content is about 25%; immerse the bamboo square in warm water at about 70°C for 24 hours to soften ; The blade of planing cutter and bamboo fiber direction included angle α are 15 ° and carry out planing (see image 3 ), to obtain a width of 500mm and a thickness of 0.3mm carbonized thin bamboo product. The rest are the same as Example 1.

Embodiment 3

[0025] Example 3. The difference between the production method of sliced thin bamboo slices in this example and example 1 is: select pretreated natural color bamboo slices and carbonized bamboo slices, and combine them into integrated bamboo pieces according to needs; pressurize and soak until the moisture content is about 80%; Bamboo is immersed in warm water at about 35°C to soften for 72 hours; the angle α between the blade of the cutting tool and the bamboo fiber direction is 45° for planing, and the thin bamboo with a width of 105mm and a thickness of 1.0mm is obtained. product. The rest are the same as Example 1.

[0026] See Figure 4 , This example sliced thin bamboo chip 5 is coated with adhesive layer 6 and non-woven fabric layer 7, makes it difficult for cracking, strength increases, is convenient to process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com