Electric steel plate capable of relieving stress annealing and having high performance of solvent-resisting

A technology of stress relief annealing and solvent resistance, applied in the directions of inorganic material magnetism, thin material handling, transportation and packaging, etc., can solve the problems of weak adhesion, poor punching, weak coating, etc., to achieve stress relief annealing, Excellent solvent resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] On the surface of an electrical steel sheet with a thickness of 0.5 mm, apply a coating solution containing resin, silica, and alkali metals, with a part of Cl and S below the specified amount, by roll coating, and bake the sheet at a temperature of 150°C Let it cool, form the insulating coating shown in Table 1, and manufacture an electrical steel sheet with the insulating coating.

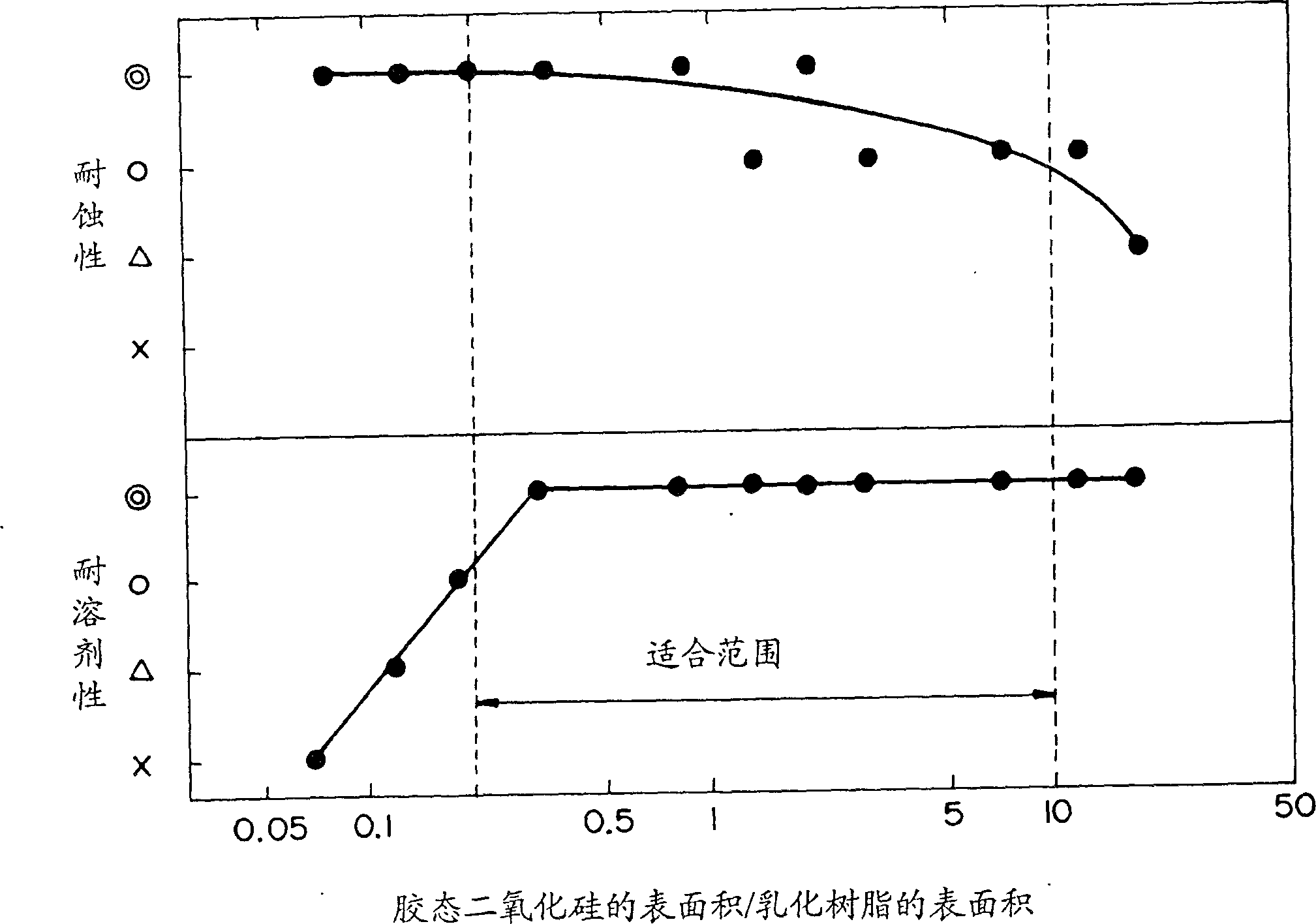

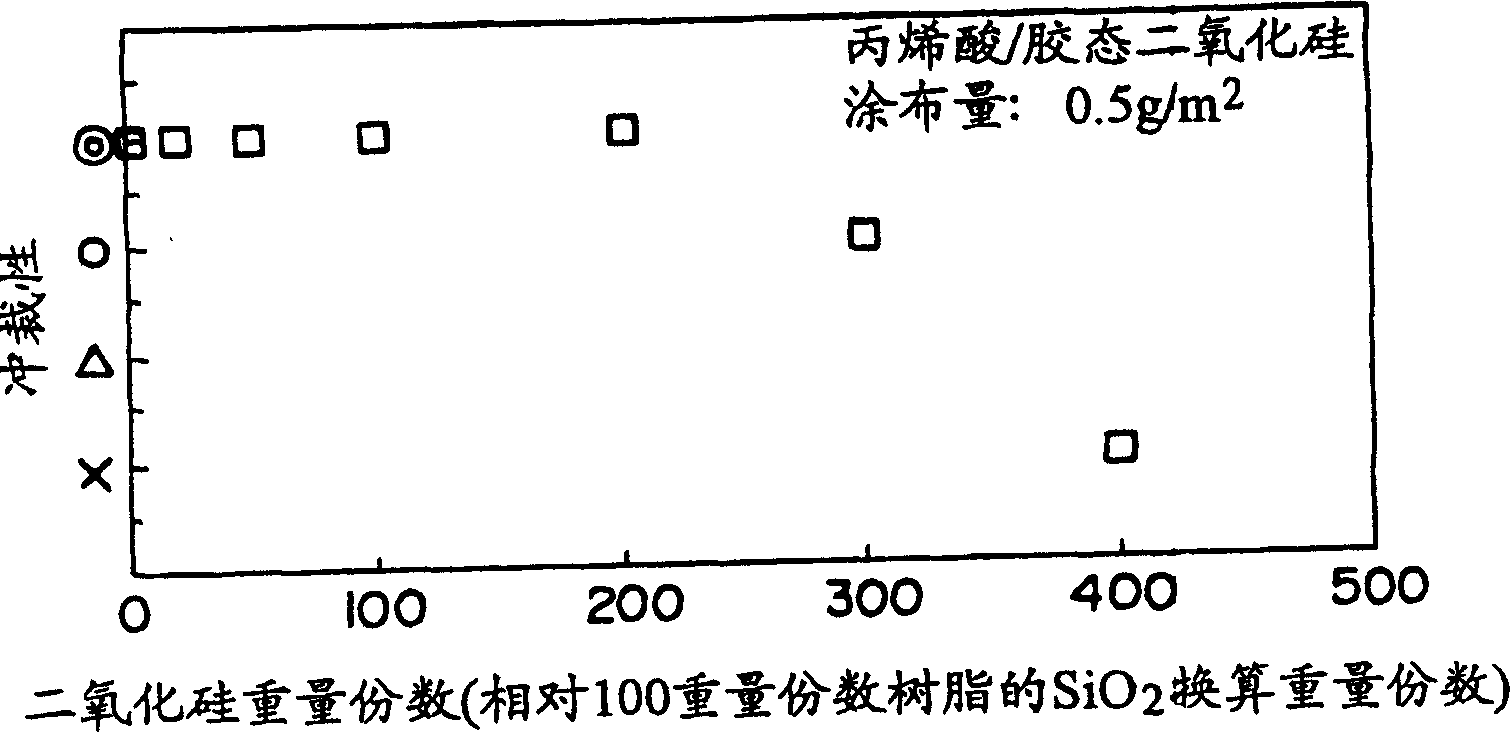

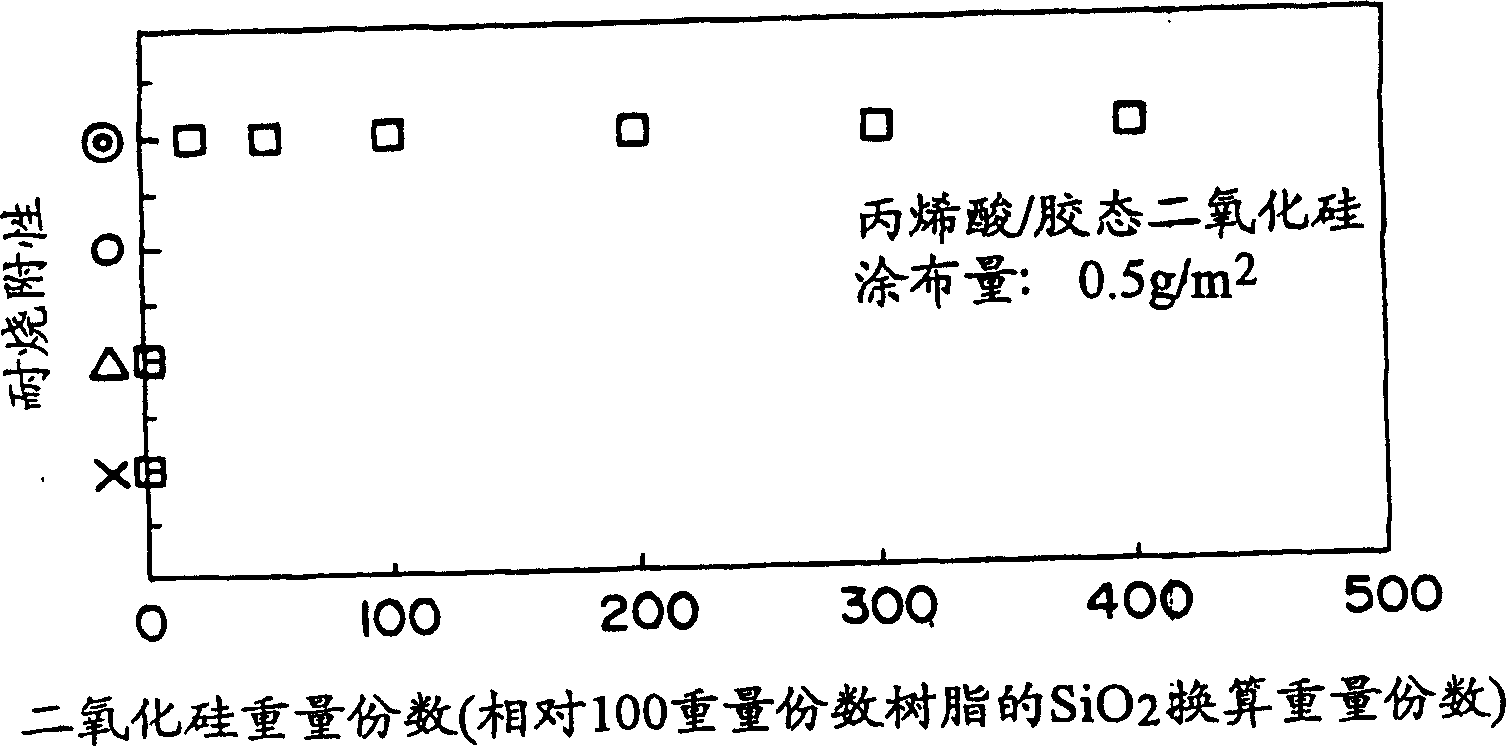

[0100] The obtained electrical steel sheet with an insulating coating was evaluated or measured for solvent resistance, punchability, corrosion resistance before and after stress relief annealing, adhesion, and seizure resistance by the following methods. The evaluation results of solvent resistance, product plate and annealed plate corrosion resistance are shown in Table 1, and further, the effect of silica weight on punchability, the effect of silica weight on seizure resistance, and the effect of coating amount on The influence of the coating adhesion of the product plate and the anneal...

Embodiment 2

[0139] The coatings described in Table 2 were formed on the surface of an electrical steel sheet having a thickness of 0.5 mm. Coating was performed using a roll coater, and after reaching a plate temperature of 150° C., baking and cooling were performed, and then subjected to various performance tests. Solvent resistance, punchability, adhesion (product board, annealed board), and seizure resistance were measured and evaluated in the same manner as in Example 1.

[0140] Membrane-forming

[0141] The coating appearance after baking at a plate temperature of 150° C. was visually observed and evaluated in accordance with the following criteria.

[0142] ◎: Shows a uniform appearance, no cracks and bubbles, no stickiness

[0143] ○: There are some cracks and bubbles

[0144] △: Many cracks and bubbles, some stickiness

[0145] ×: There are many cracks and air bubbles, and it is remarkably sticky

[0146] As is clear from Table 2, the examples of the present invention are al...

Embodiment 3

[0148] The coatings described in Table 3 were formed on the surface of an electrical steel sheet having a thickness of 0.5 mm. Coating was performed using a roll coater, and after reaching a plate temperature of 150° C., baking was performed and left to cool, each performance test was performed. In the same manner as in Examples 1 and 2, film forming properties, solvent resistance, punchability, adhesion (product sheet, annealed sheet), and seizure resistance were measured and evaluated.

[0149] It can be clearly seen from Table 3 that the examples of the present invention are all electrical steel sheets with insulating coatings excellent in solvent resistance, punchability, corrosion resistance before and after stress relief annealing, adhesion, and seizure resistance. In addition, the examples in the table are based on the improvement of only the focused performance, but they are also examples of further improvement of other various performances. Regarding other performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com