U-shaped gas collection-parellel current combined sprue of proton exchange membrance fuel cell

A fuel cell and parallel flow technology, applied in fuel cell additives, fuel cell control, fuel cell components, etc., can solve the problems of increasing reaction gas diffusion resistance, reducing reaction gas concentration, etc., to reduce the degree of cathode submersion, The effect of improved reaction rate and excellent work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

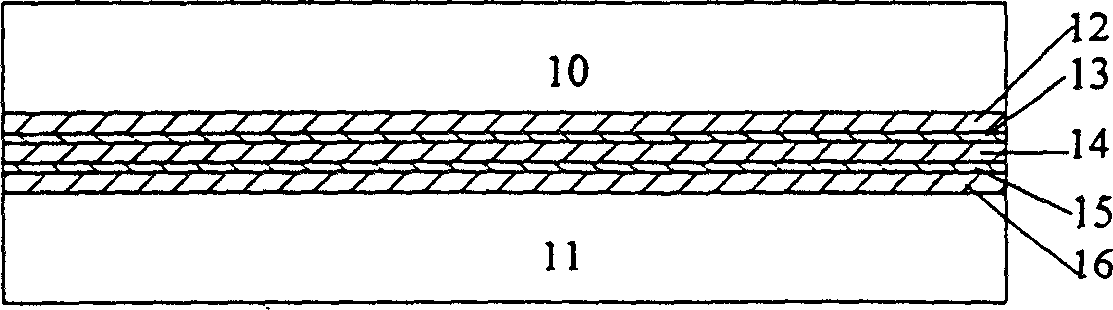

[0020] In order to better understand the technical solution of the present invention, further description will be made below in conjunction with the accompanying drawings.

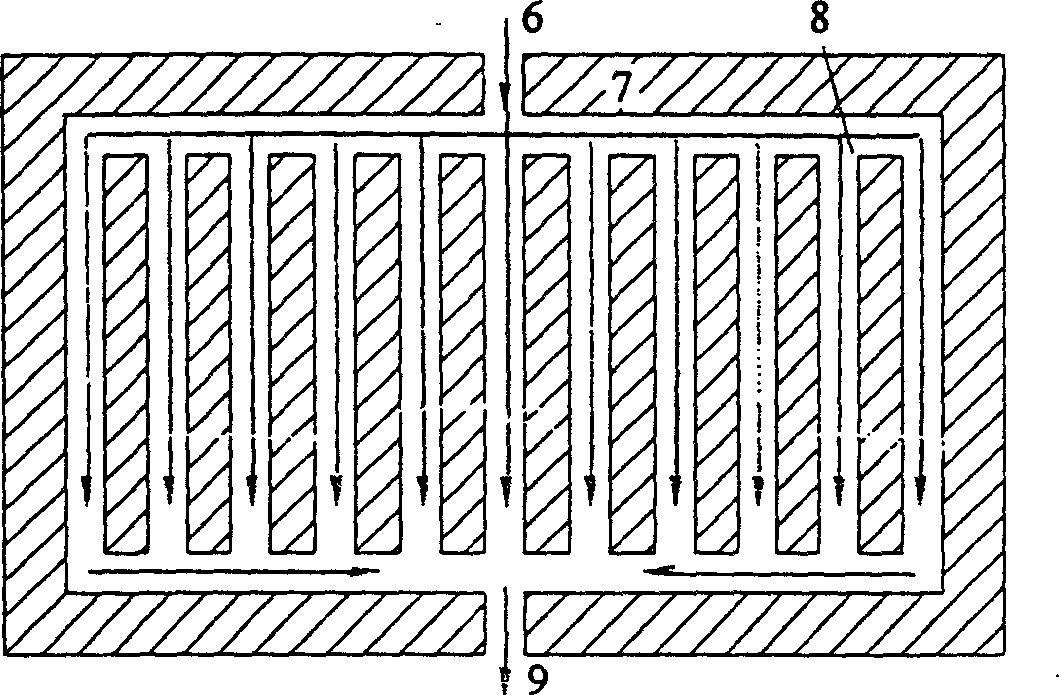

[0021] The U-shaped gas collection-parallel flow combined channel structure of the proton exchange membrane fuel cell provided by the present invention is as follows: image 3 shown. The so-called combined flow channel is to select different forms of flow channels according to the working characteristics of the fuel cell cathode and anode. The battery cathode of the present invention adopts a U-shaped flow channel 10, and the anode adopts a parallel flow channel 11, the cathode U-shaped flow channel 10 is above the battery, and the anode parallel flow channel 11 is below the battery.

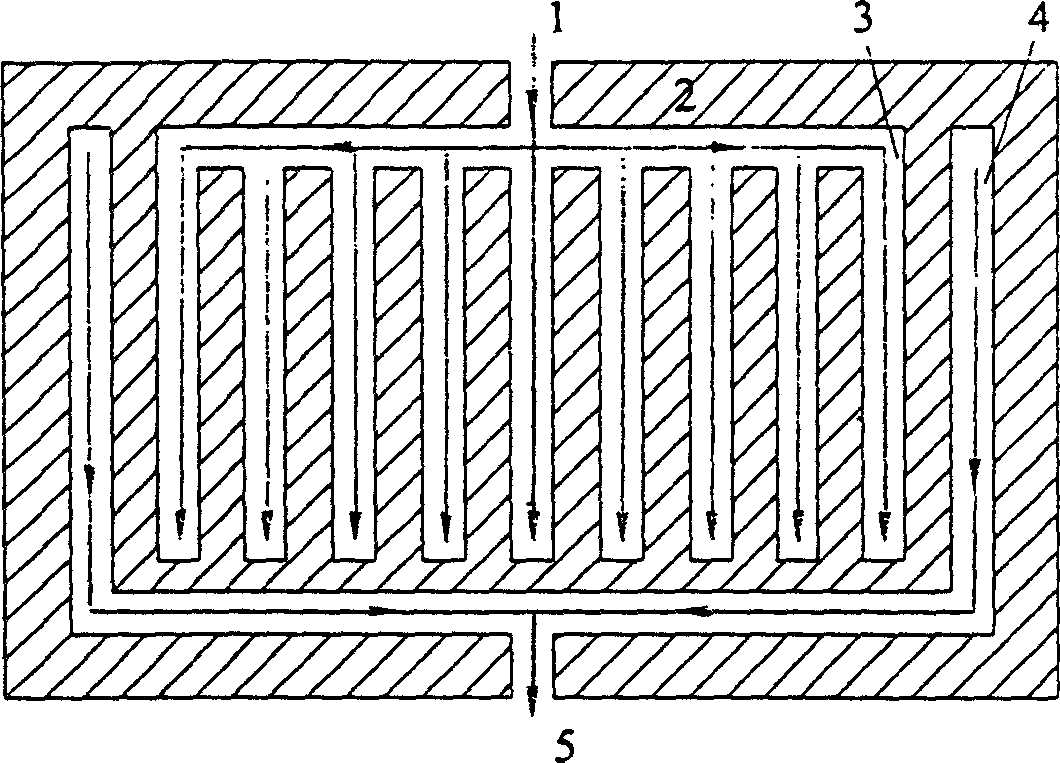

[0022] The structure of the cathode U-shaped flow collector 10 of the present invention is as follows: figure 1 As shown, it is divided into two parts, the parallel cathode air intake channel 3 and the cathode U-shaped exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com