Washup-flotation process for stacked bauxite

A bauxite and ore washing technology, applied in flotation, solid separation, wet separation, etc., can solve problems such as clogged screens, and achieve the effects of saving water, increasing production capacity and alkali consumption, and reducing cultivated land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

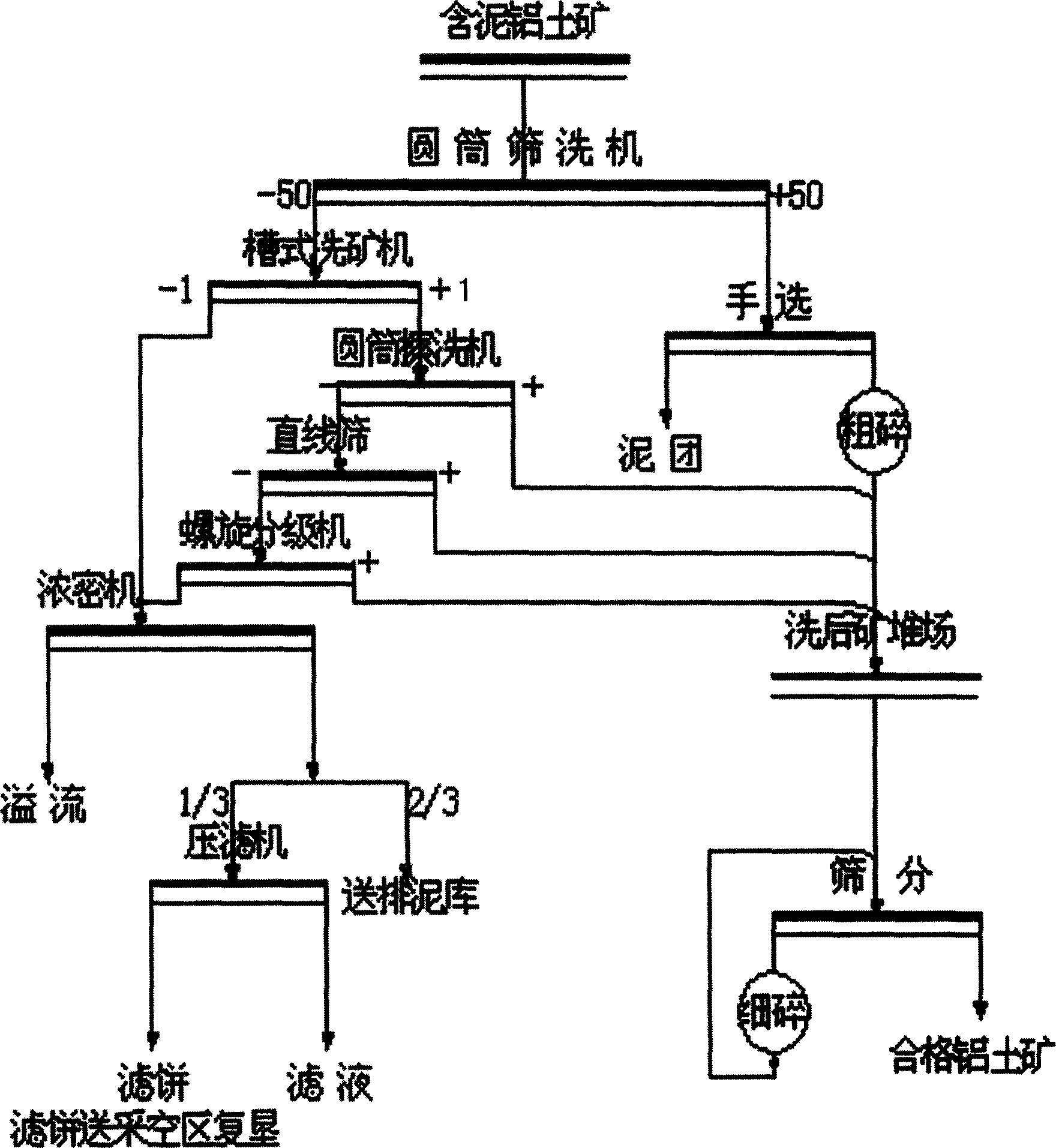

Image

Examples

Embodiment 1

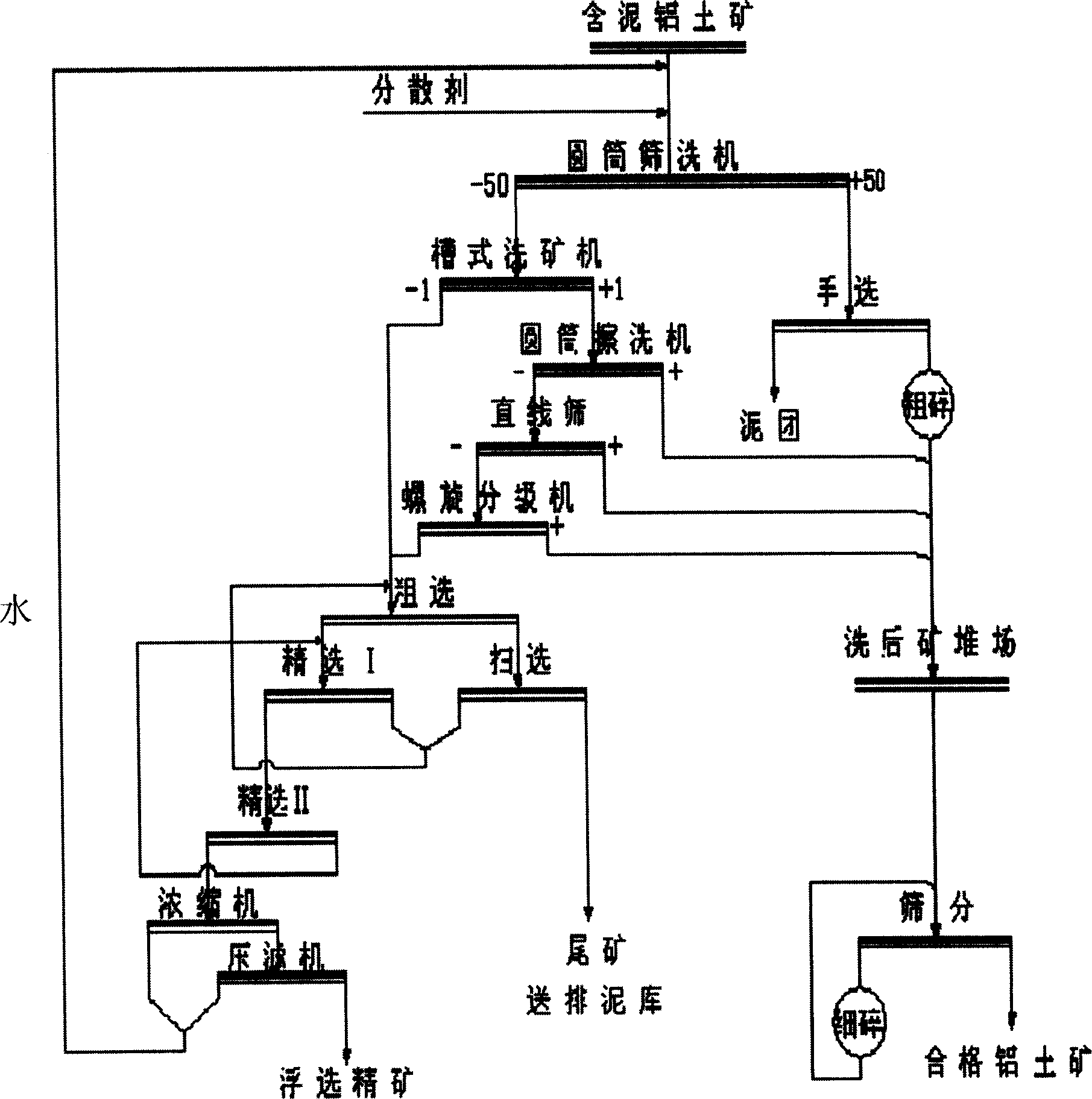

[0034] figure 2 It is a flow chart of embodiment 1 of heaped bauxite washing-flotation process of the present invention. On the basis of not changing the original equipment, the technique of this embodiment includes the following stages:

[0035] Feed the mud-containing bauxite into the drum screen washing machine, and at the same time add the dispersant sodium carbonate or sodium hydroxide into the drum screen washing machine, and wash with water is the first stage;

[0036] After washing, the ore with a particle size greater than or equal to 50mm is hand-selected to obtain the washed concentrate, which specifically includes hand-selected, coarse crushing, ore stockpiling after washing, and fine crushing and screening to obtain qualified bauxite; the ore with a particle size of less than 50mm passes through the tank The ore washing machine is the second stage;

[0037] Through the ore washing of the trough type ore washing machine, the ore with a particle size greater than...

Embodiment 2

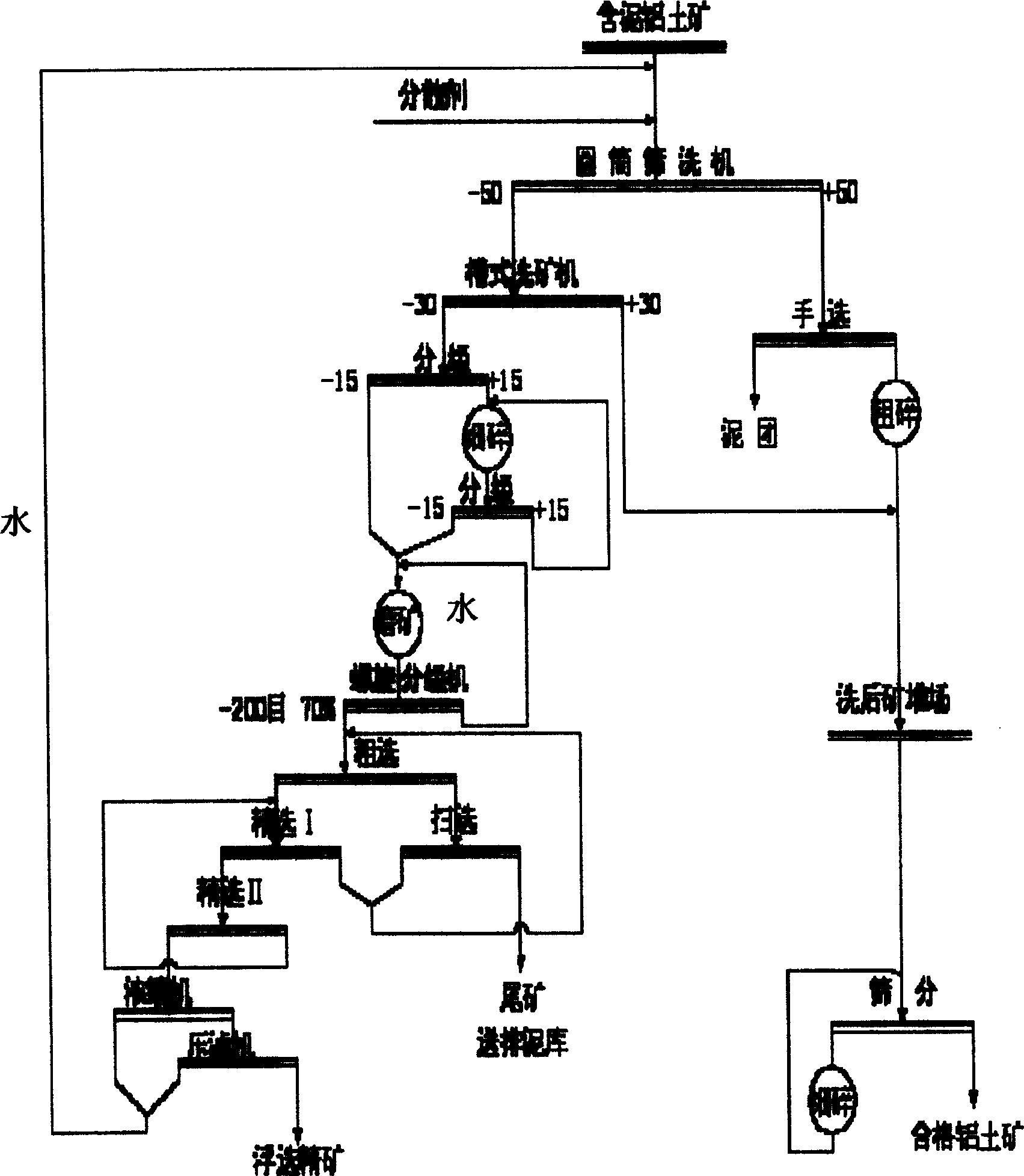

[0043] image 3 It is the flow chart of the second embodiment of the stacked bauxite washing-flotation process of the present invention.

[0044] This embodiment is set for the grade measurement results of ores with a particle size greater than 50mm and below. For ores with a particle size greater than or equal to 50mm, the A / S is up to 13.86 and for ores with a particle size of 30-50mm, the A / S is as high as 15 or more, while 10- The A / S of 30mm-sized ore dropped rapidly to 6.58; the A / S of 10mm to 1mm-sized ore dropped to 3.89.

[0045] For this reason, this embodiment proposes that the particle size of ore washing and flotation should be 30 mm. That is to adjust the screen of the trough washing machine to 30mm. The technique of the present embodiment comprises the following stages:

[0046] Feed the mud-containing bauxite into the drum screen washing machine, and at the same time add the dispersant sodium carbonate or sodium hydroxide into the drum screen washing machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com