Heating device for casting sand

A technology of heating device and foundry sand, which is applied in the field of sand heating device, can solve problems such as failure to meet process requirements, achieve sufficient heat exchange, high thermal efficiency, and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

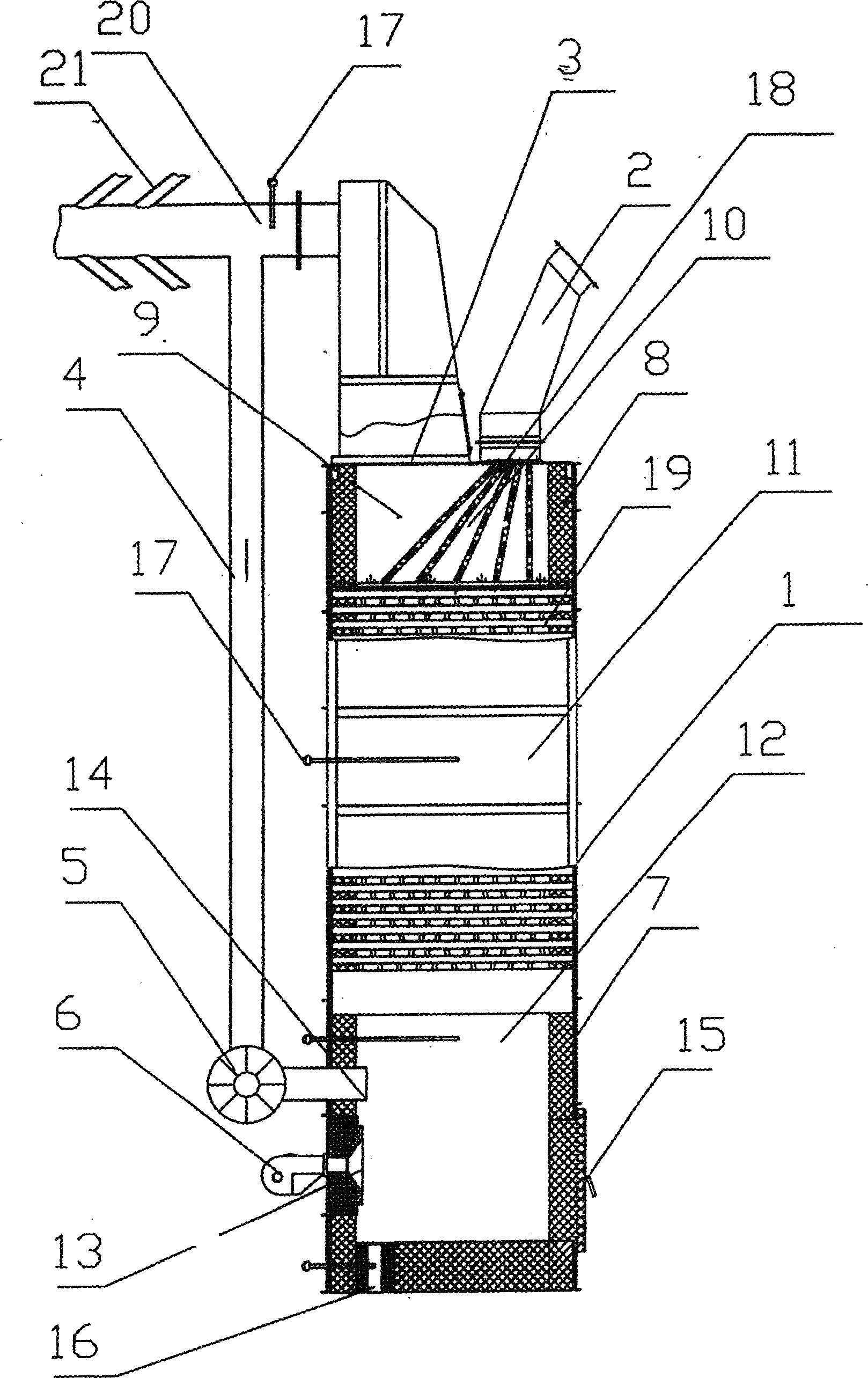

[0019] like figure 1 Shown, a kind of sand heating device for foundry, it has a vertical body of furnace 1, and its height is greater than its transverse size, and there is sand inlet 18, smoke exhaust and dust removal port 3 and the dust removal pipe 20 that is connected with it at the top, The sand inlet 18 has a sand inlet trough 2, and a cold air pipe 21 is provided on the dust removal pipe 20; the smoke return pipe 4 located outside the furnace body 1 is connected to the dust removal pipe 20 at one end, and the smoke return inlet 14 at the other end. 4 is provided with boiler induced draft fan 5. There is a combustion port 13 on the outer side of the lower section close to the body of heater 1, and a burner 6 is connected thereto. The furnace wall of body of furnace 1 is made up of steel plate skin, insulation layer 7 and innermost refractory brick 8. The internal structure is from top to bottom: sand separation chamber 9, there are many sand separation pipes 10 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com