Method for heat treatment of train wheel with improved turning ability

A heat treatment method and processing performance technology, applied in heat treatment furnaces, heat treatment equipment, wheels characterized by rail running parts, etc., can solve the problems of reduced labor productivity in machining, poor turning performance of wheels, and increased turning difficulty. Achieve the effect of reducing the maximum contact stress, improving turning performance and reducing tool loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The wheel components used in the following preferred modes and comparative samples are: C: 0.62, Si: 0.29, Mn: 0.74, P: 0.018, S: 0.003, and the rest: trace amount.

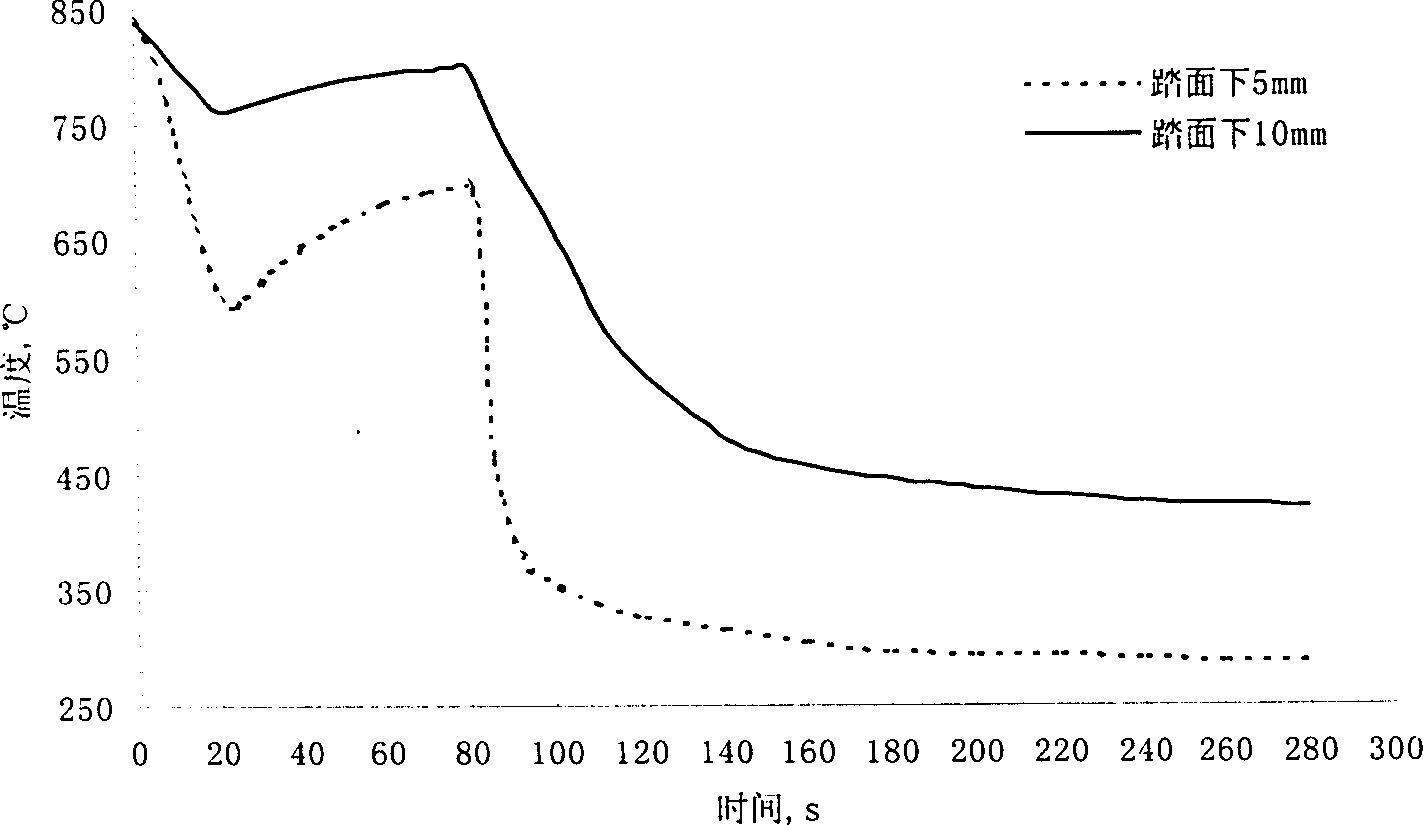

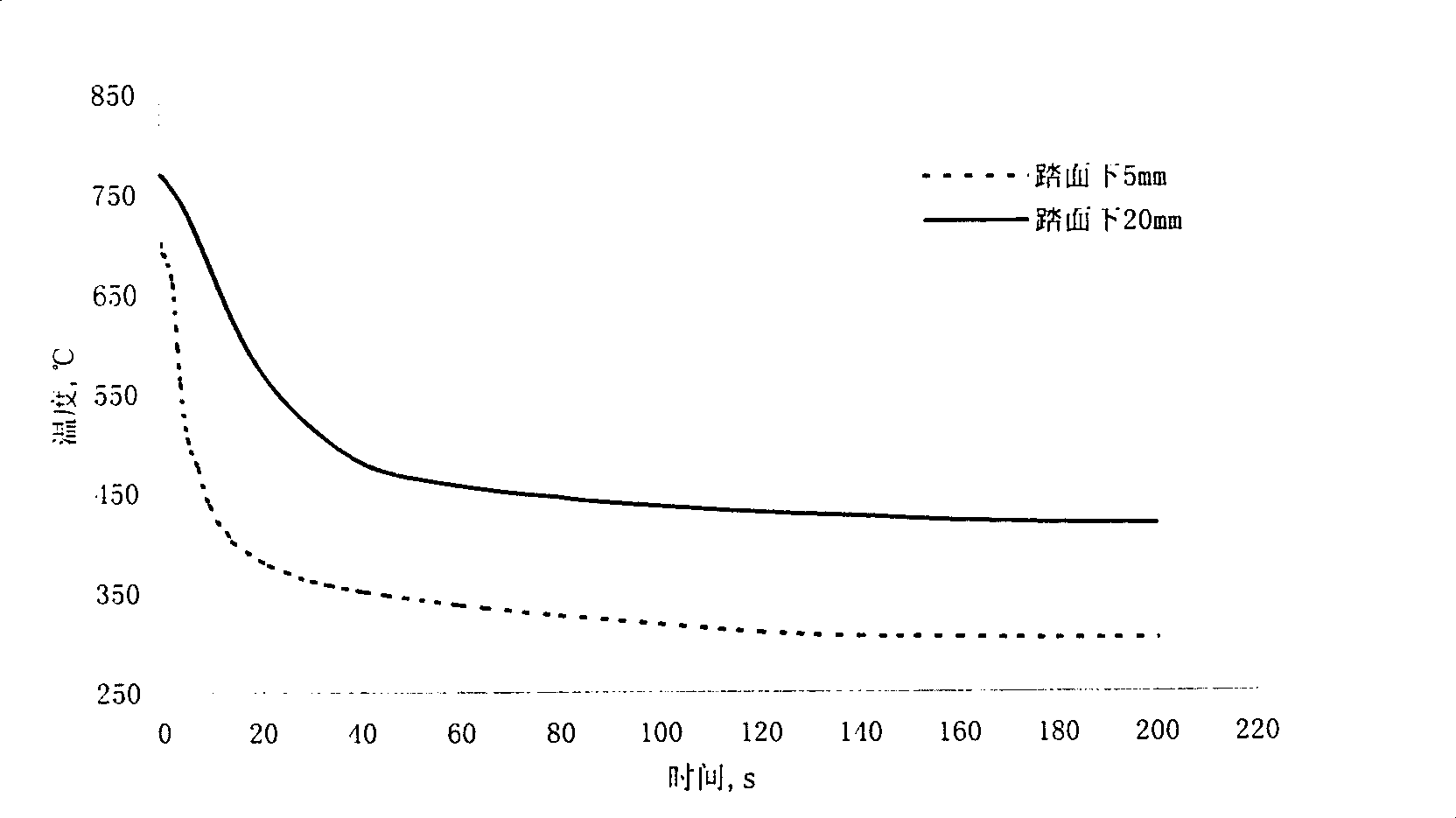

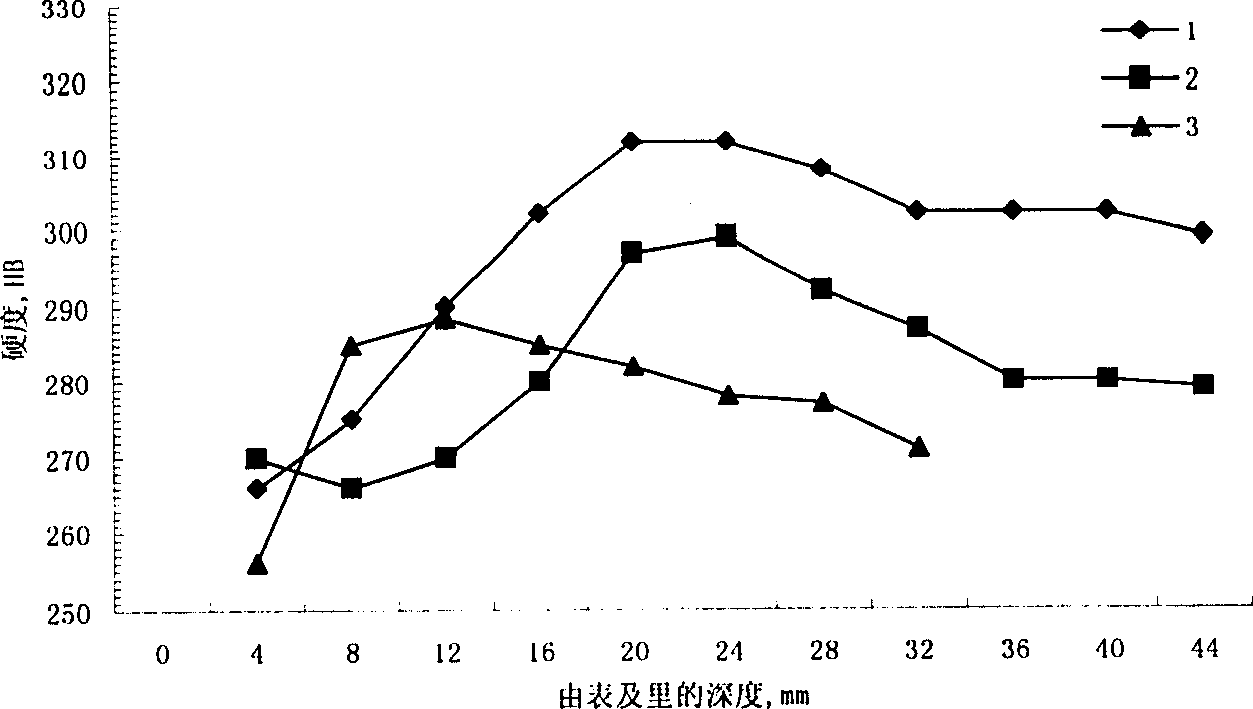

[0013] Preferred way 1: Place the train wheels in a high-temperature state maintained in the austenite region in a horizontal quenching table. During the rotation of the wheel, the tread is cooled by spraying water for 20-25 seconds. The temperature measured by the thermocouple embedded 5mm below the tread is cooled to a certain temperature range below the austenite transformation temperature of the steel. The exact Said to be 595-610 ℃, stop spraying water, at this time the surface temperature of the tread is between 550-565 ℃, and a layer of 5-8mm thick pearlite structure is formed on the surface of the wheel tread. After the water spraying is stopped, the wheel is left to stand for 60-70 seconds to use the heat conduction in the high-temperature zone inside the rim to make the surface temperature rise a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com