Aluminum alloy extruded bar and its preparation process

A preparation process and technology of aluminum alloy, applied in the field of aluminum alloy extruded bar and its preparation process, can solve the problems of easy sticking of knives and wrinkling, poor machinability of alloy, etc., and achieve the elimination of dendrite segregation and good turning performance. , the effect of good extrusion formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

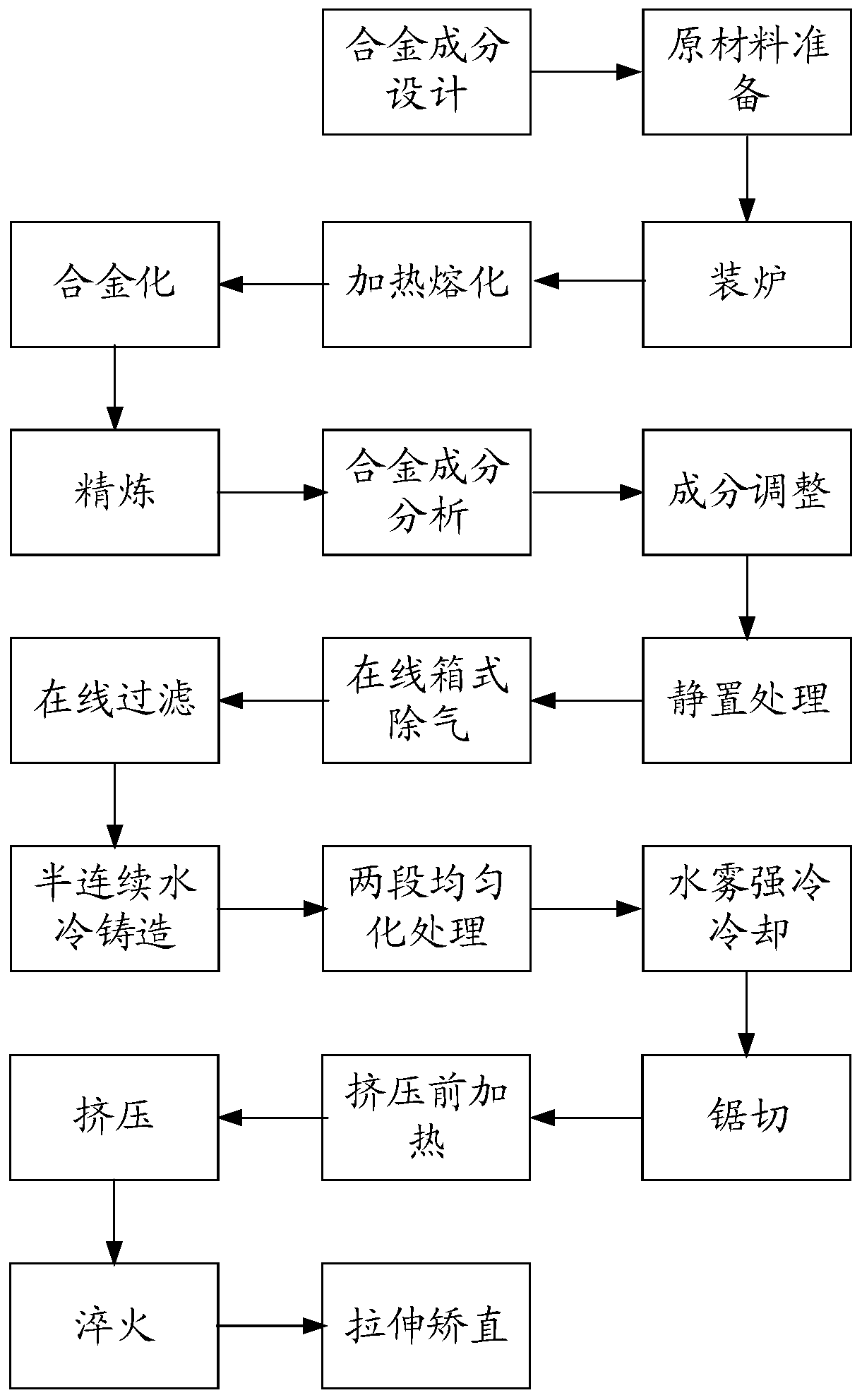

Method used

Image

Examples

Embodiment 1-4

[0042] The aluminum alloy extruded rod described in Examples 1-4 includes the components shown in Table 1 by mass percentage, and the content of other impurities is not more than 0.15%, and the balance is Al.

[0043] components Example 1 Example 2 Example 3 Example 4 Si 0.4 0.5 0.45 0.4 Fe 0.6 0.6 0.55 0.6 Cu 0.2 0.2 0.15 0.2 mn 1 1.2 1.1 1 Ti 0.03 0.05 0.02 0.03

[0044] Table 1

[0045] The raw materials for preparing the above-mentioned aluminum alloy extruded rods are as follows:

[0046] Aluminum ingots: Aluminum ingots with the brand name Al99.7 are used, and the mass percentage of Al in the aluminum ingots is more than 99.70%, which meets the standard GB / T 1196-2008 "Aluminum Ingots for Remelting";

[0047] Alloy additives (aluminum-silicon, aluminum-manganese, aluminum-iron, aluminum-copper): use AlSi12, AlMn13, AlFe20 and AlCu40 master alloys respectively, and the quality meets the YS / T282-2000 stand...

Embodiment 1

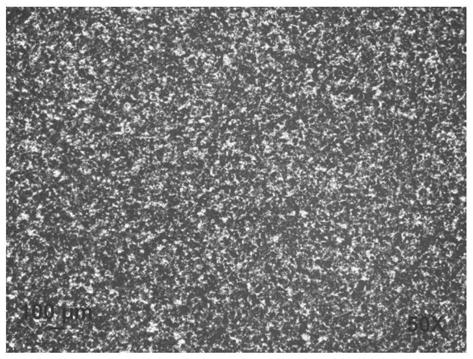

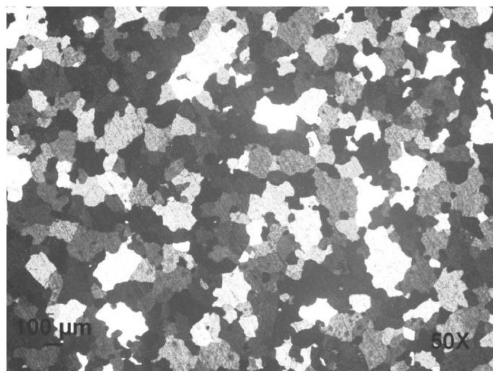

[0090] The alloy flanging described in embodiment 1 and the cutting surface are smooth, such as Figure 4 shown. Comparative example 2 flanging cracking such as Figure 5 As shown, comparative example 4 flanging is wrinkled as Figure 6 shown. Through the comparison of the above experimental results and data, it can be seen that the reasonable ratio of the alloy components and the design of the corresponding process conditions in the present invention effectively avoid the formation of complete recrystallization or mixed crystals of the material, and obtain good extrusion formability, At the same time, it has good turning performance and is suitable for machining materials such as flanging and CNC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com