Method and system for reducing NO discharging by collecting and refiring fine coal powder in tertiary wind

A technology of fine coal powder and secondary air, which is applied in the direction of combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of fly ash combustibles increase, high moisture content, steam temperature fluctuations, etc., to achieve small changes, The effect of fine coal powder particle size and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

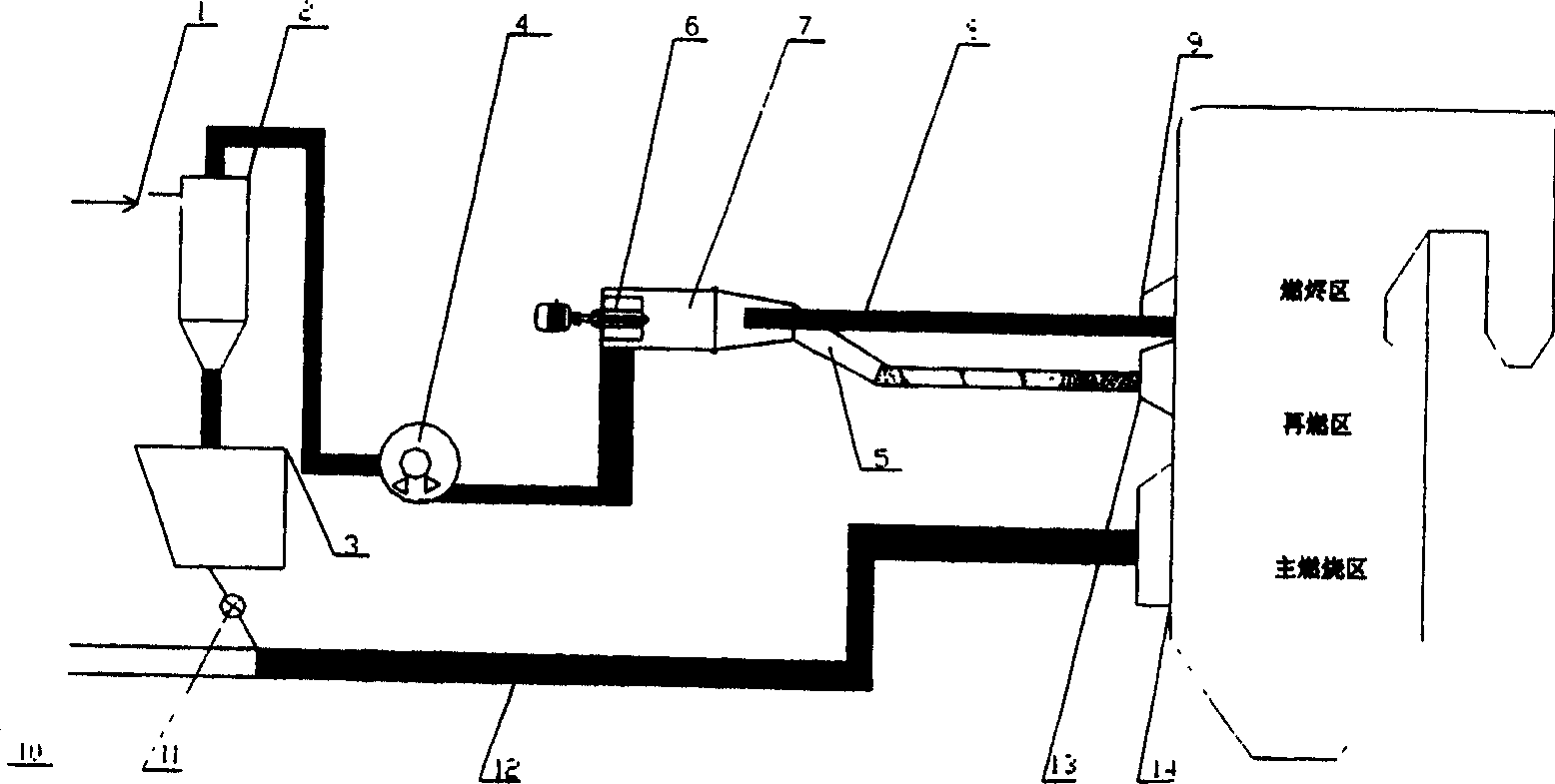

[0013] The tertiary air concentration and reburning NOx emission reduction system in the power plant boiler pulverization system includes a fine powder separator 2, a powder exhaust fan 4, and a rotating blade separator connected in sequence, and the outlets of the separators are respectively connected to the burn-off air nozzle 9 And the reburning fuel nozzle 13 of the furnace, the air powder inlet pipe 1 is provided on the fine powder separator and is connected with the main powder bin 3, the main powder feeding machine 11, the hot air pipe 10, the primary air pipe 12, and the furnace main burner 14 in sequence , it is characterized in that: the separator is a rotating blade separator 7, the air inlet section of the separator is provided with rotating blades 6, and the rotating blades are driven by a motor, and the air outlet of the separator is provided with a rich coal powder delivery pipe 5 With thin pulverized coal powder feeding pipe 8, the rich pulverized coal powder fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com