Technique for power supply to air exhausing fan of electromagnetic stove

A power supply device and exhaust fan technology, which is applied in household heating, heating fuel, household stove/stove, etc., can solve problems such as short life, waste of electric energy, and loud motor noise, so as to improve service life, save electric energy, and improve work efficiency. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

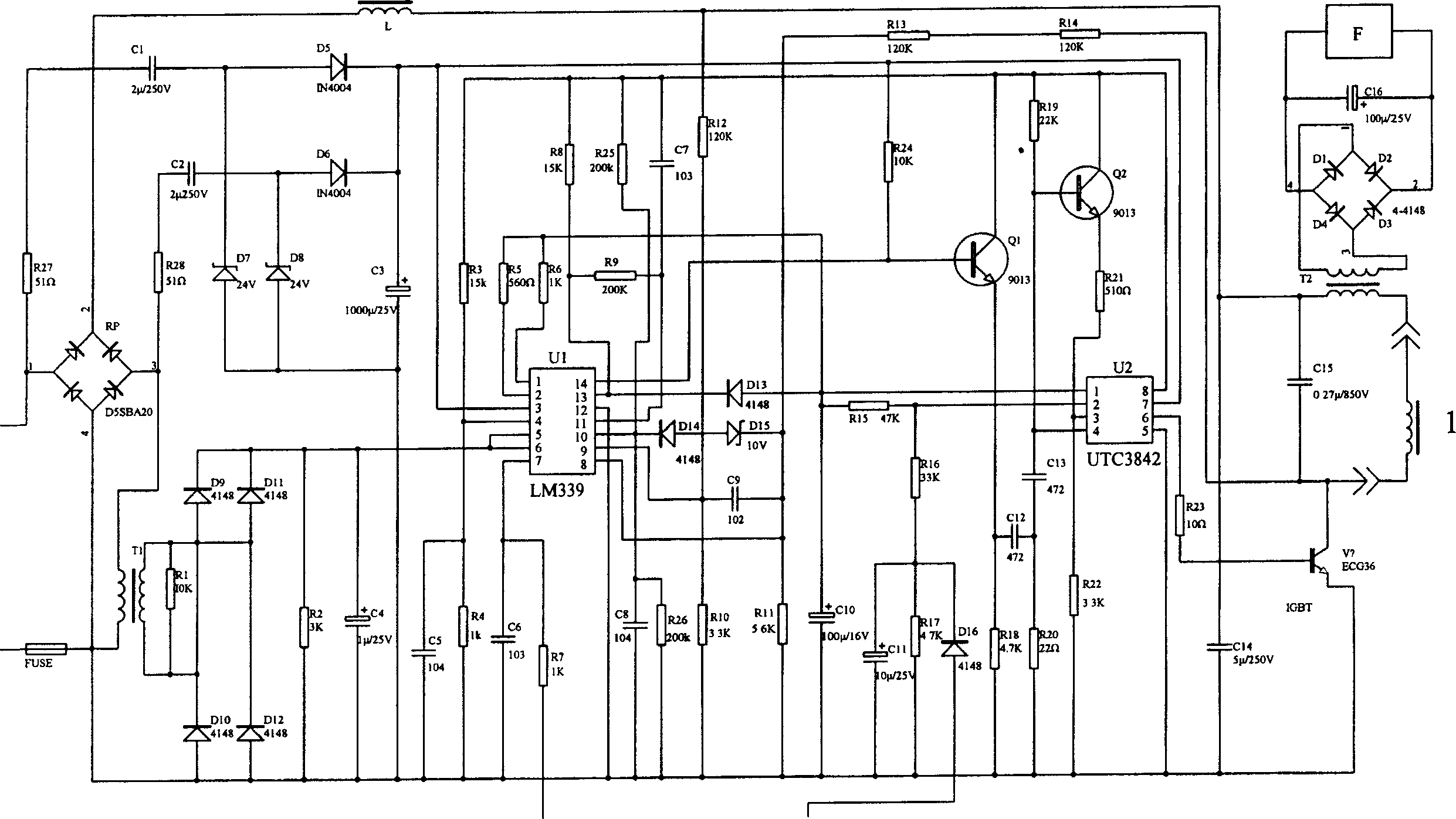

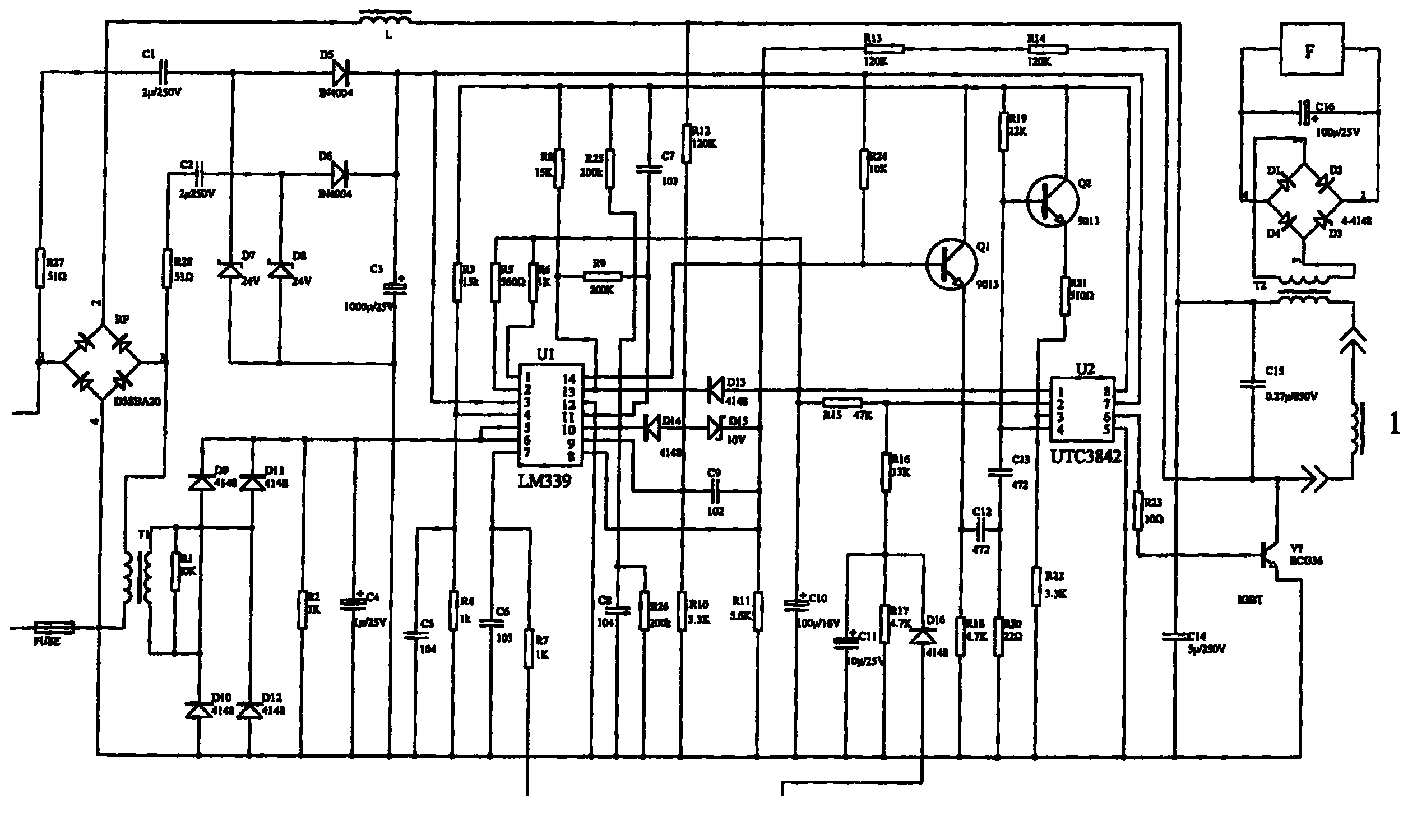

[0007] As shown in the figure, mains power (220V / 50HZ), through fuse FUSE, current transformer T 1 Connect to rectifier bridge RP for rectification, inductance L, capacitance C 14 After filtering, a pulsating DC voltage with a peak value of about 300V is obtained. Fig. 1 shows that the exhaust fan of the induction cooker according to an embodiment of the present invention is powered by a current transformer T 2 , the primary coil of the current transformer is connected in series with the inductive heating coil 1 of the induction cooker, and the secondary coil is passed through the rectifier diode D 1 、D 2 、D 3 、D 4 After rectification, the capacitor C 16 After filtering, it is directly supplied to exhaust fan F as power supply. According to the principle of current transformer, the ratio of the primary coil current to the secondary coil current is equal to the ratio of the secondary coil turns to the primary coil turns. When the turns ratio is constant, the secondary coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com