Process for large-scale preparation of 2-hydroxyethyl pyridine

A technology of hydroxyethylpyridine and industrial scale, which is applied in the technical field of preparing 2-hydroxyethylpyridine on an industrial scale, can solve the problems such as the lack of supply of industrial-scale 2-hydroxyethylpyridine products, and achieve simple and convenient production process and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 1

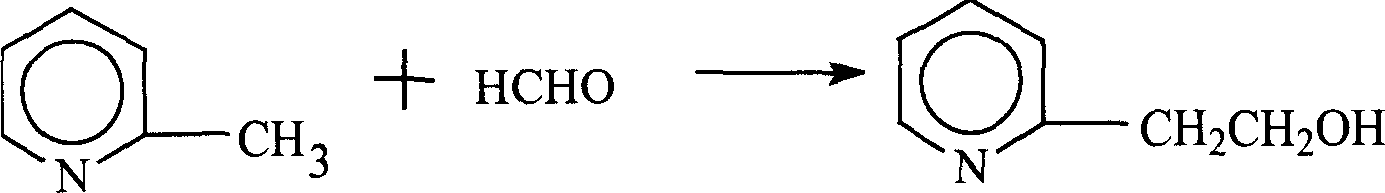

[0015] Embodiment 1 one, reaction equation is as follows:

[0016]

[0017] 2. Specific process operation

[0018] Using 2-methylpyridine as the starting material, it condenses with paraformaldehyde in the presence of a catalyst to generate 2-hydroxyethylpyridine.

[0019] 1. Raw material situation

[0020] 2-Methylpyridine (2-methylpyridine) is commercially available, with a content ≥ 99% and a moisture content ≤ 0.2%;

[0021] Paraformaldehyde (Paraformaldehyde, also known as solid formaldehyde) is commercially available, solid particles, content 90-95%, formic acid content ≤ 0.03%;

[0022] Benzoic acid (benzoic acid, commercially available industrial product, content ≥ 98.5%) is used as catalyst.

[0023] 2. Weight ratio

[0024] 2-picoline:paraformaldehyde:catalyst=1:0.12:0.012

[0025] Feeding quantity is: 2-picoline (content 99.5%, w / w) 93.5kg, pure 93.0kg

[0026] Paraformaldehyde (content 90.5%, w / w) 12.33kg, pure 11.16kg

[0027] Benzoic acid (content 98.5%...

Embodiment 2

[0030] Embodiment 2 catalyst is commercially available chloroacetic acid (monochloroacetic acid), monochloroacetic acid content ≥ 99%, dichloroacetic acid content ≤ 0.5%,

[0031] 2-picoline: paraformaldehyde: catalyst=1: 0.03: 0.003;

[0032] Feeding quantity is: 2-picoline (content 99.5%, w / w) 93.5kg, pure 93.0kg

[0033] Paraformaldehyde (content 91.5%, w / w) 3.05kg, pure 2.79kg

[0034] Chloroacetic acid (content 99.5%, w / w) 0.2804kg, pure 0.28kg

[0035] The reaction temperature is 90-100°C, the reaction time is 10-12 hours, and the finished product of 2-hydroxyethylpyridine is obtained. The finished product has a yield of 107.52kg, a content of 98.12%, and a pure conversion of 105.50kg, based on 2-picoline, with a yield of 85.77%; a light yellow transparent liquid with a moisture content of 0.48%; the rest are the same as in Example 1.

Embodiment 3

[0036] Embodiment 3 Catalyst uses commercially available commodity acetic acid (acetic acid), acetic acid content ≥ 96%,

[0037] 2-picoline: paraformaldehyde: catalyst=1: 0.12: 0.003;

[0038] Feeding quantity is: 2-picoline (content 99.5%) 93.5kg, convert pure 93.0kg

[0039] Paraformaldehyde (content 90.5%) 12.33kg, pure 11.16kg

[0040] Acetic acid (content 96.5%) 0.2804kg, converted to pure 0.28kg

[0041] The reaction temperature is 170-180°C, the reaction time is 15 hours, the yield of the finished product is 115.96kg, the content is 98.58%, and the pure product is 114.31kg. Based on 2-picoline, the yield is 92.94%. It is a colorless and transparent liquid with a water content of 0.48%. The rest With embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com