Method for operating offset press and its control device, offset press and offset printing material

A technology for offset printing presses and offset printing plates, which is applied to general parts of printing machinery, printing presses, measuring devices, etc., and can solve problems such as insufficient ink and excessive wetting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

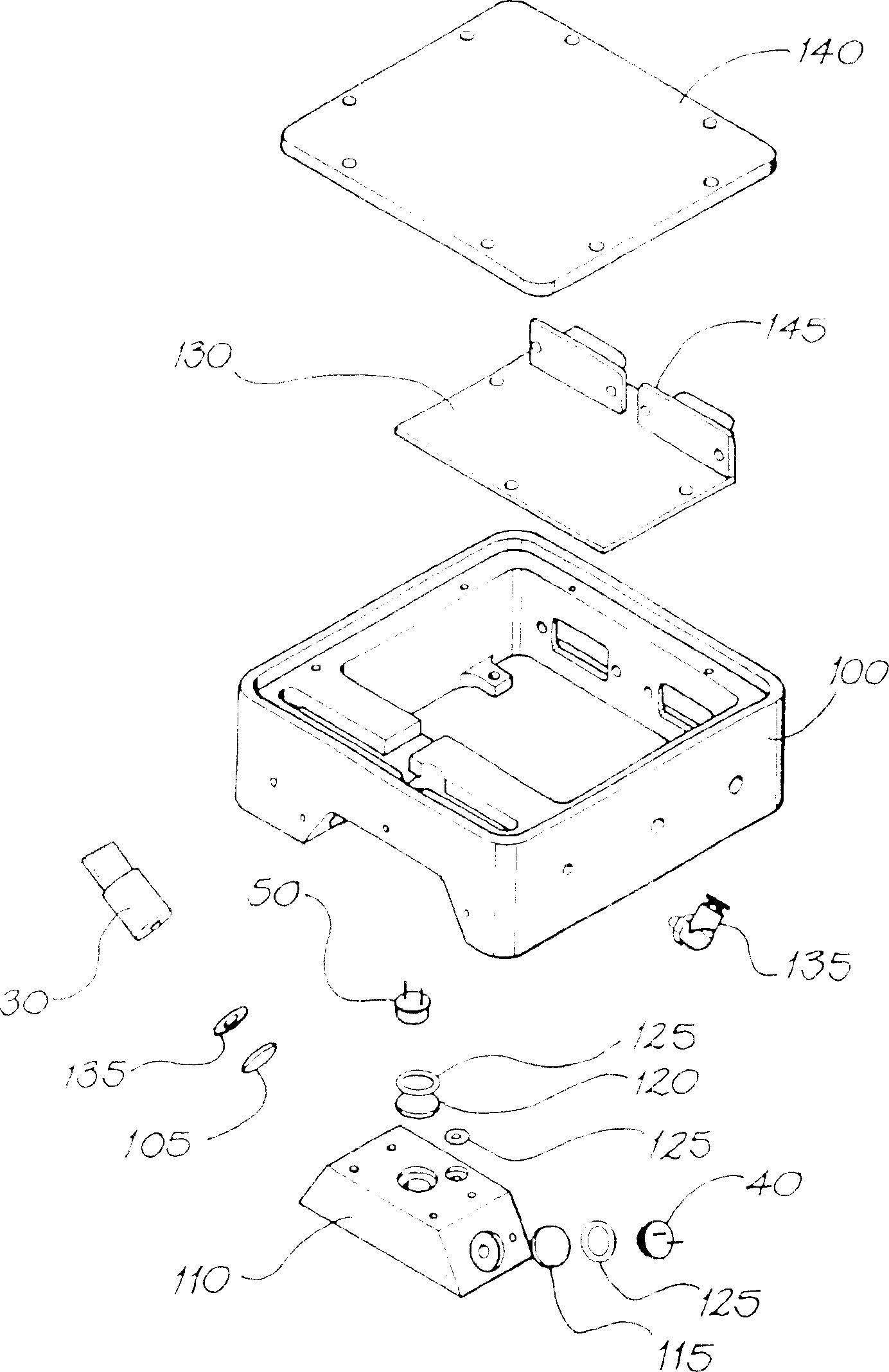

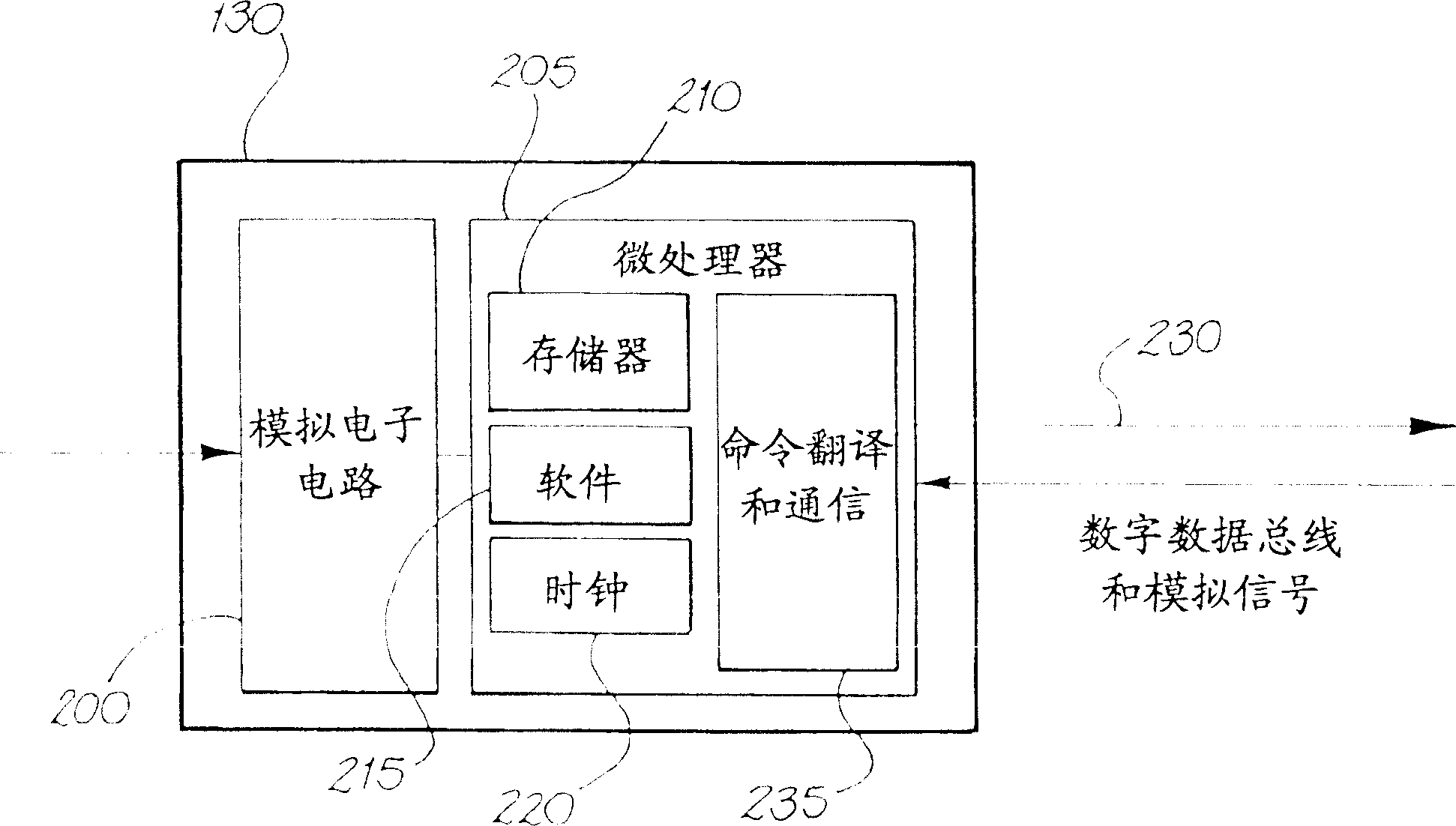

[0087] measuring instrument

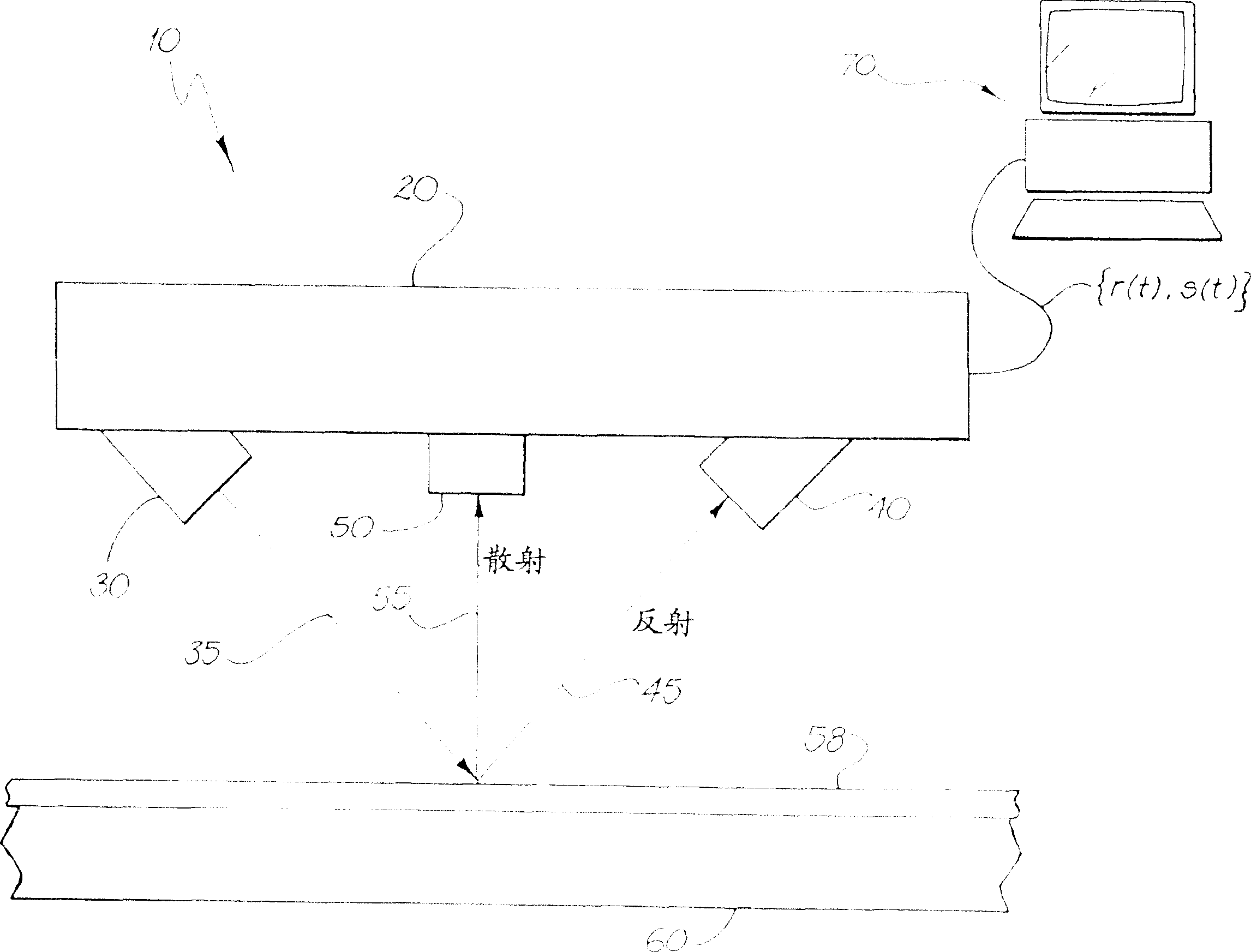

[0088] figure 1 An instrument 10 is shown in which a housing 20 containing electronic components (to be described hereinafter) contains a direct light source 30 , a reflected light detector 40 and a scattered light detector 50 . The light of the light source is incident according to the incident path 35 and interacts with the (ideal) film surface 58 on the printing plate 60 , causing reflections on the specular path 45 and the diffuse path 55 .

[0089] The direct light source 30 may be any light source, but is preferably a laser because of its availability and ease of obtaining a light source directed at a given target. Detectors 40 and 50 are readily implemented by commercially available silicon cell detectors. For clarity, the optical filters and detectors 40, 50 associated with the light source 30 are not shown.

[0090] More specifically, the light source 30 is typically a 650 nm, 3 mW diode laser module with a collimating lens 300-0360-78...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com