Pump jetting propeller

A thruster and pump injection technology, which is applied to ship propulsion, propulsion components, pumps, etc., to achieve high efficiency and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

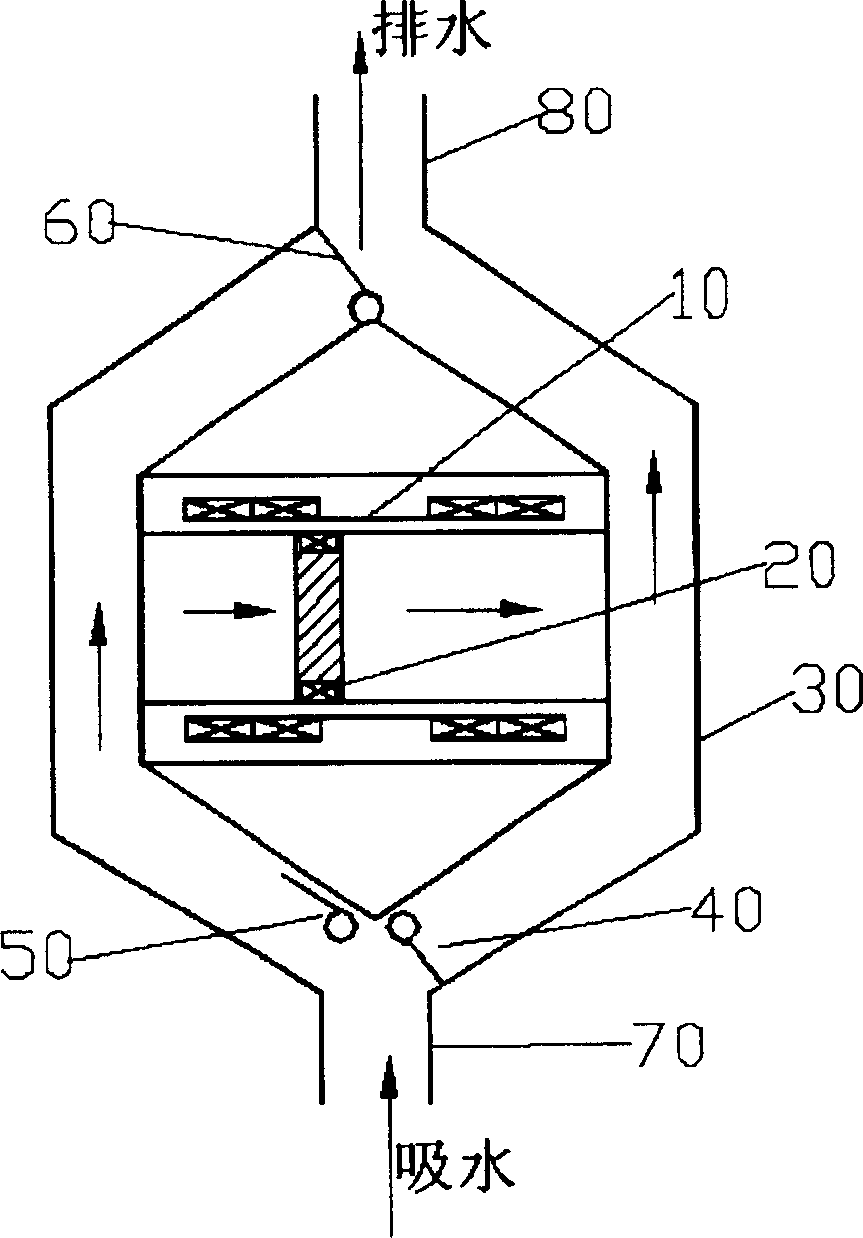

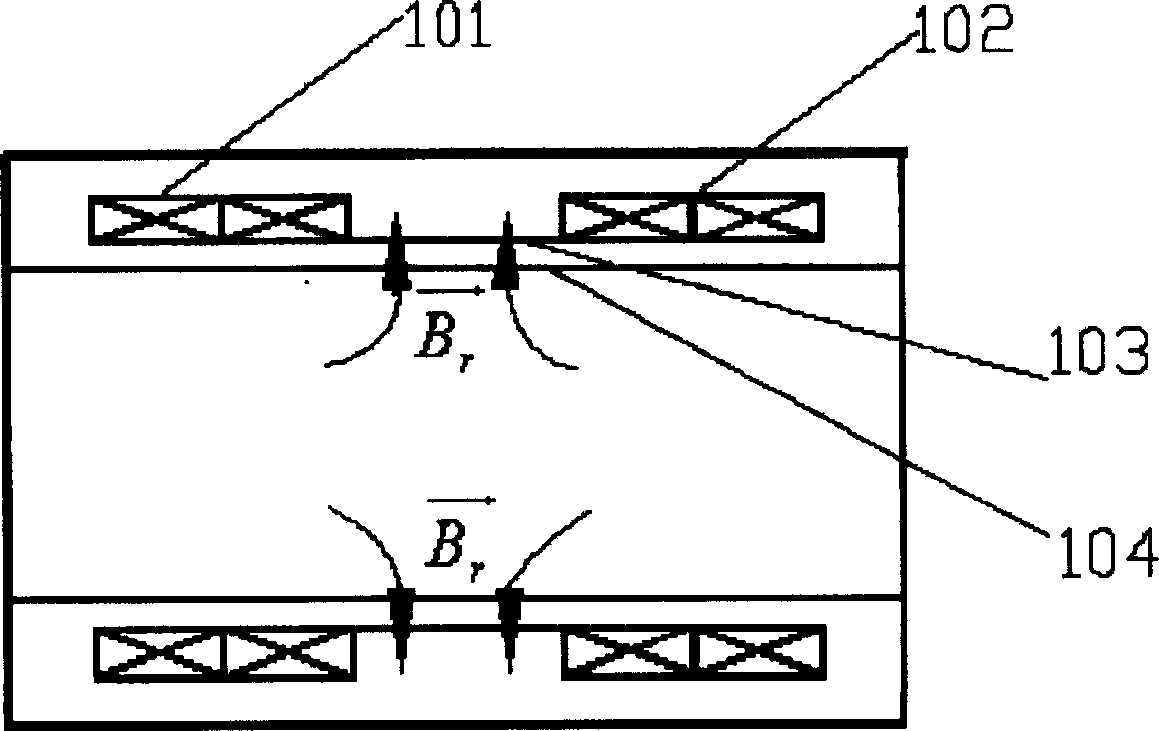

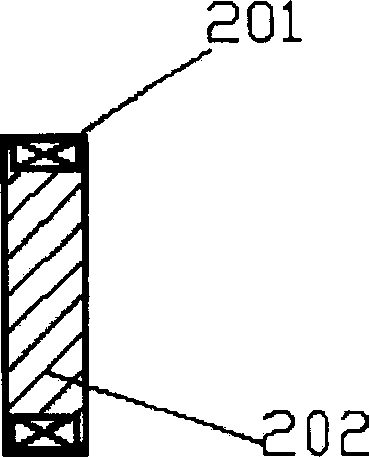

[0013] figure 1 It is the structure of the superconducting electromagnetic piston pump-jet thruster which is one of the specific embodiments of the present invention. It includes a superconducting antipolar magnet 10, an electromagnetic piston 20, a hydrodynamic chamber 30, a right one-way valve 40, a left one-way valve 50, a reversing valve 60, a water suction port 70, and a water discharge port 80. The structure of the superconducting antipolar magnet 10 is as follows figure 2 As shown, it includes two sets of superconducting helical coils 101 and 102 , a coil core 103 , and a room temperature bore core 104 . The structure of electromagnetic piston 20 is as image 3 As shown, it includes a normally conducting solenoid coil 201 and a piston 202 .

[0014] After the two sets of superconducting solenoidal coils 101 and 102 in the superconducting antipolar magnet 10 are excited with currents in opposite directions, a radial diameter is generated in the room temperature inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com