Inductive current absolute position sensor by using code rail type staff and read out head

An absolute position and sensor technology, which is applied in the use of electric/magnetic devices to transmit sensing components, the use of electric devices, and the conversion of sensor outputs, etc., can solve problems such as failure to provide a sensing system, and achieve high accuracy and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

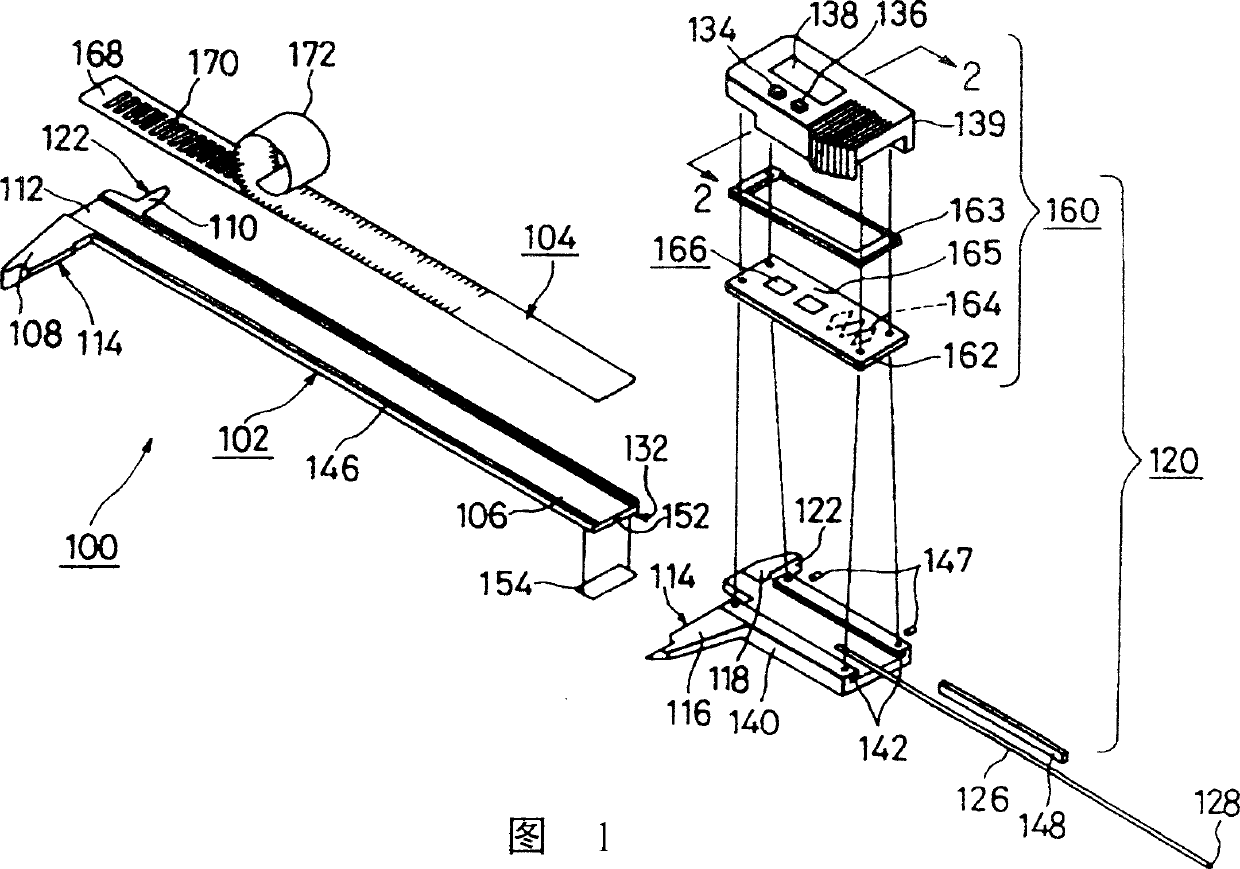

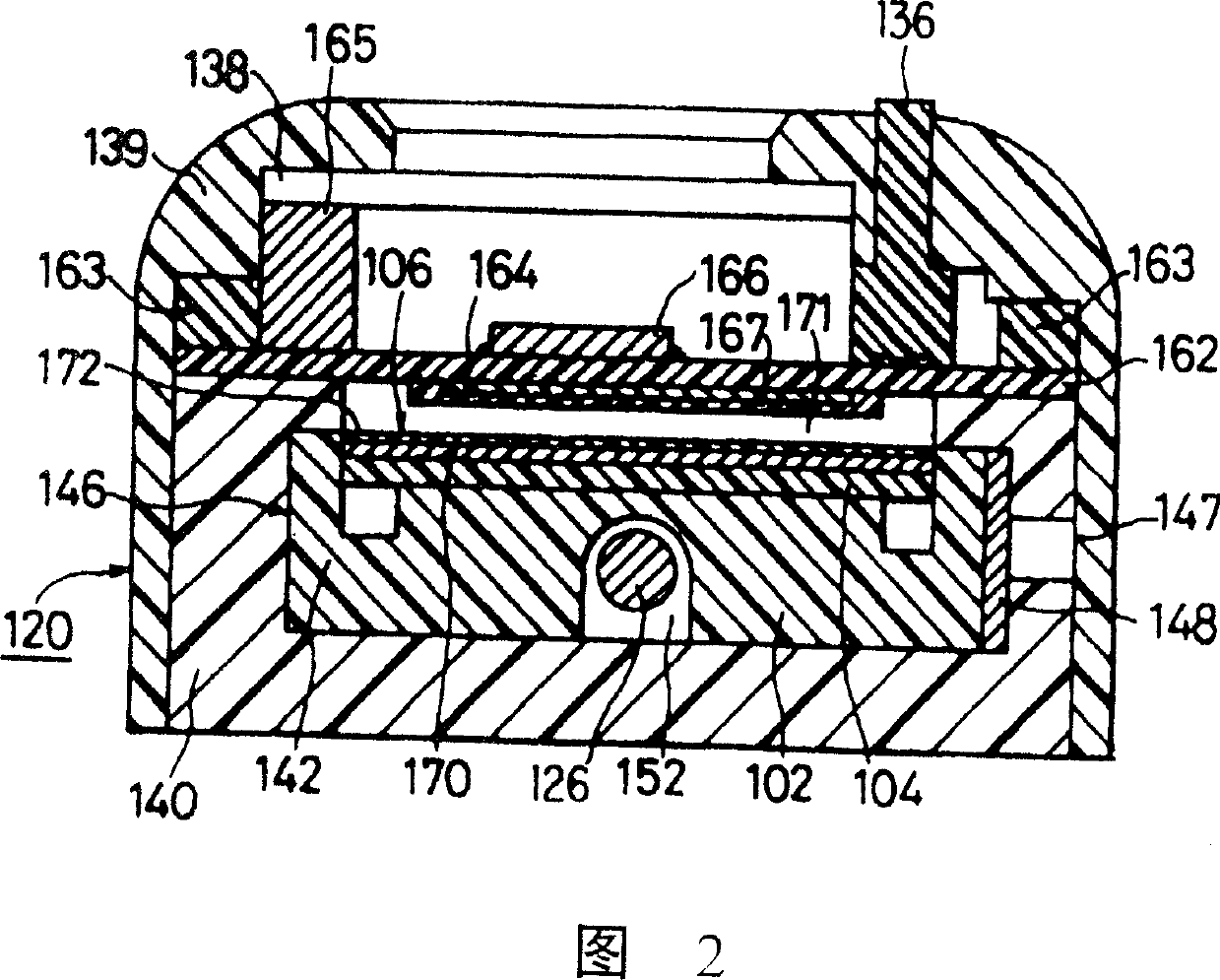

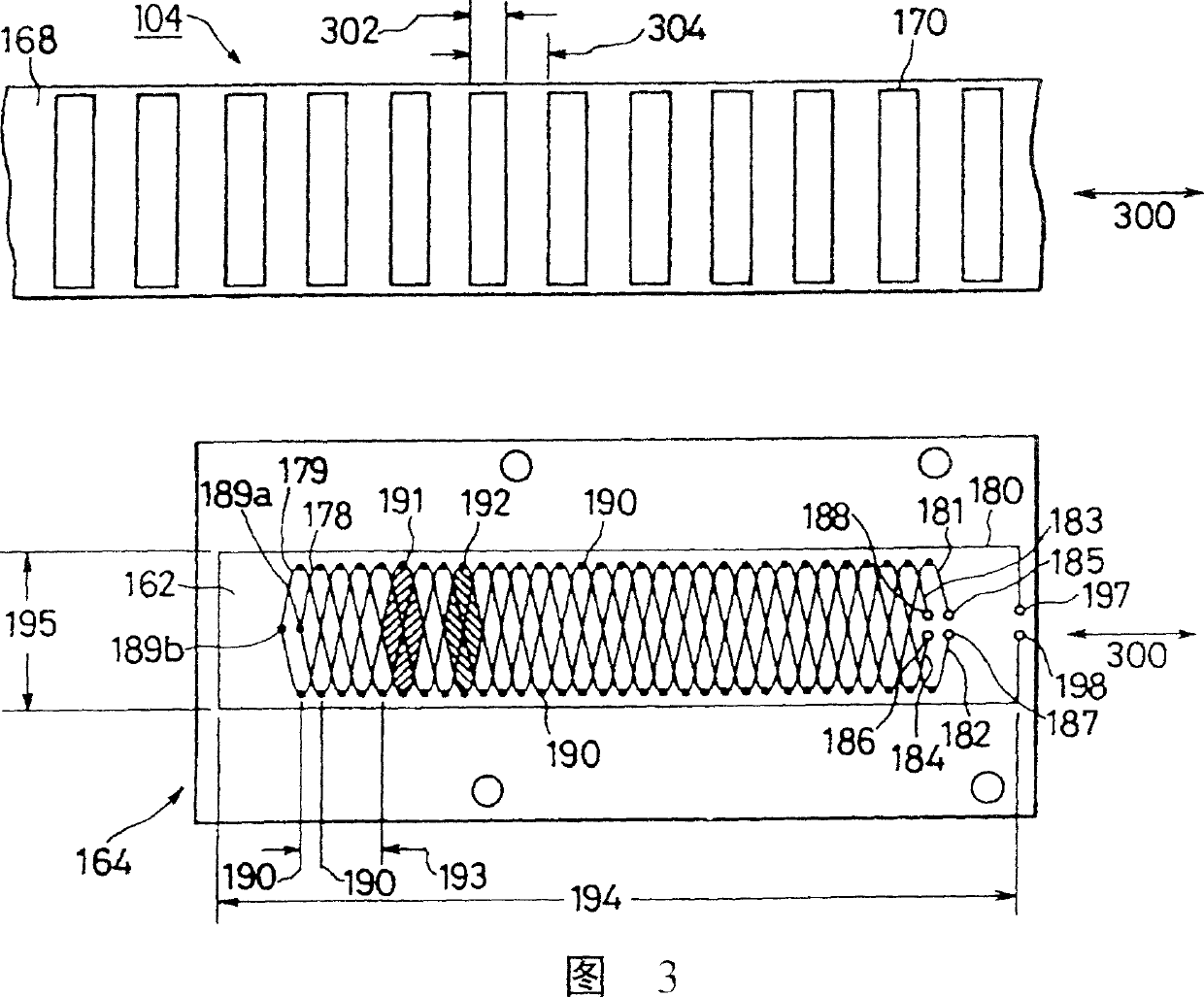

[0093] For convenience and clarity, the working principle, design factors, and configuration of the sensor winding of the present invention are described with reference to the incremental measurement type sensor used in the caliper shown in FIGS. 1-3. The basic description of the working principle of the incremental measurement sensor winding is suitable for understanding and designing the constituent windings used in the absolute sensor of the present invention.

[0094] As shown in FIG. 1, the inductive caliper 100 includes a long beam 102. The long beam 102 is a solid or semi-rigid rod with a generally rectangular cross-section. A groove 106 is formed on the upper surface of the long beam 102. The elongated measuring rule 104 is firmly engaged in the groove 106 of the long beam 102. The groove 106 is formed in the long beam 102 at a depth equal to the thickness of the measuring rule 104. Therefore, the upper surface of the measuring rule 104 and the upper edge of the long beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com