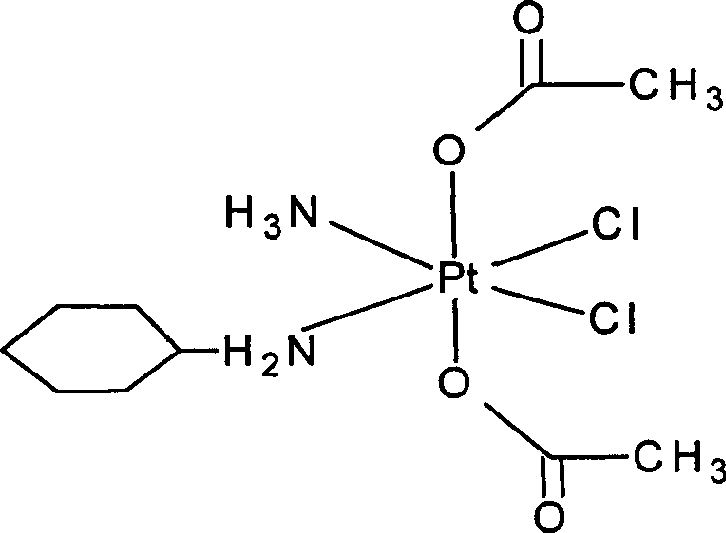

Process for purifying satraplatin

A purification method, the technology of Scitraplatin, which is applied in the field of purification of the anti-tumor drug Scitraplatin, can solve the problems of easy introduction of impurities, long synthesis route, and impact on product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

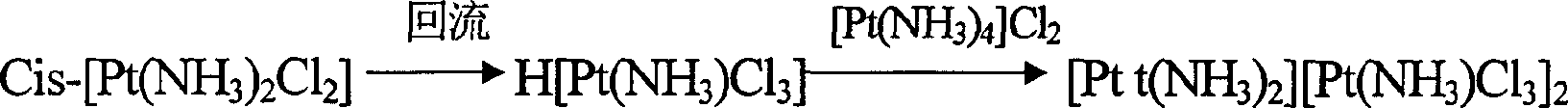

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 10 grams of the crude product containing 70% of Saite Platinum in 95ml of DMF / hydrochloric acid solution at 50°C, the volume ratio of N-N dimethylformamide:hydrochloric acid solution=5:1, and the concentration of the used hydrochloric acid solution is 0.5mol / L , glass sand funnel to filter twice, add 800ml of acid aqueous solution at 7°C to the mother liquor for reverse analysis, the concentration of hydrochloric acid aqueous solution used for reverse analysis is 0.3mol / L, let it stand for 2.5 hours, filter the separated precipitate, wash with water and ethanol three times respectively , and dried to obtain 4.5 g, the yield was 64%. After high-performance liquid chromatography analysis, the content of Saite platinum is 98.7%.

Embodiment 2

[0026] 10 grams of the crude product containing 83% of Saite Platinum was dissolved in 90ml DMF / hydrochloric acid aqueous solution at 70°C, N-N dimethylformamide:hydrochloric acid aqueous solution volume ratio=1:1, the concentration of the used hydrochloric acid aqueous solution was 1mol / L, glass Filter through sand funnel twice, add 850ml of hydrochloric acid aqueous solution at 10°C to the mother liquor for reverse analysis, the concentration of hydrochloric acid aqueous solution used for reverse analysis is 1mol / L, let it stand for 3 hours, filter the separated precipitate, wash with water and ethanol three times respectively, and dry Obtain 5.5 grams, productive rate is 66%, through high performance liquid chromatography analysis, content is 99.0%

Embodiment 3

[0028] Dissolve 10 grams of the crude product containing 91% of Saite Platinum in 85ml of DMF / hydrochloric acid solution at 100°C, the volume ratio of N-N dimethylformamide:hydrochloric acid solution=1:1, and the concentration of the used hydrochloric acid solution is 0.01mol / L . Filter twice with a glass sand funnel, add 900ml of hydrochloric acid aqueous solution at 5°C to the mother liquor for reverse analysis, the concentration of the aqueous hydrochloric acid solution used for reverse analysis is 0.01mol / L, let it stand for 2 hours, filter the separated precipitate, wash with water and ethanol three times respectively, and dry 6.1 g, 68% yield. After high performance liquid chromatography analysis, the content is 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com