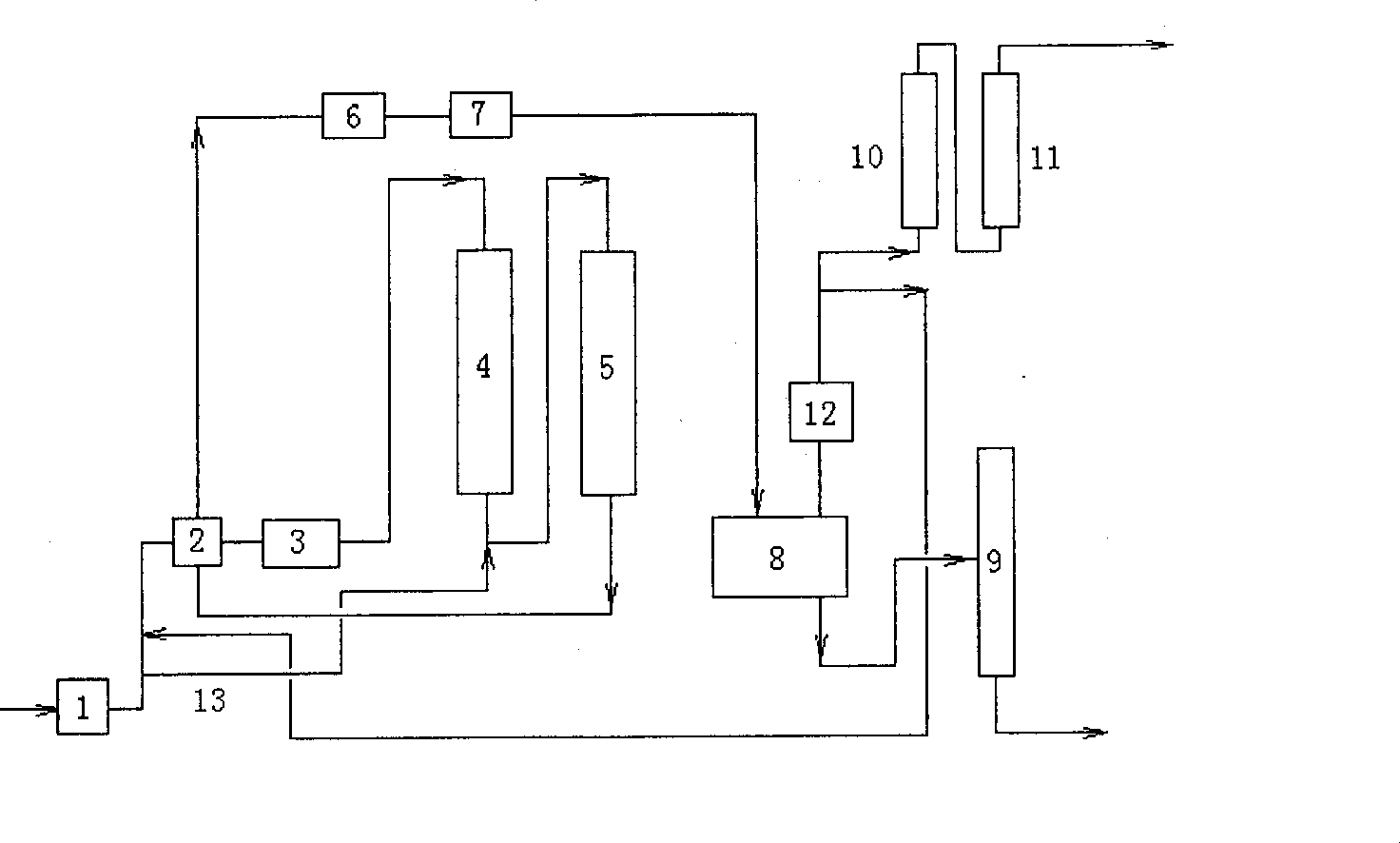

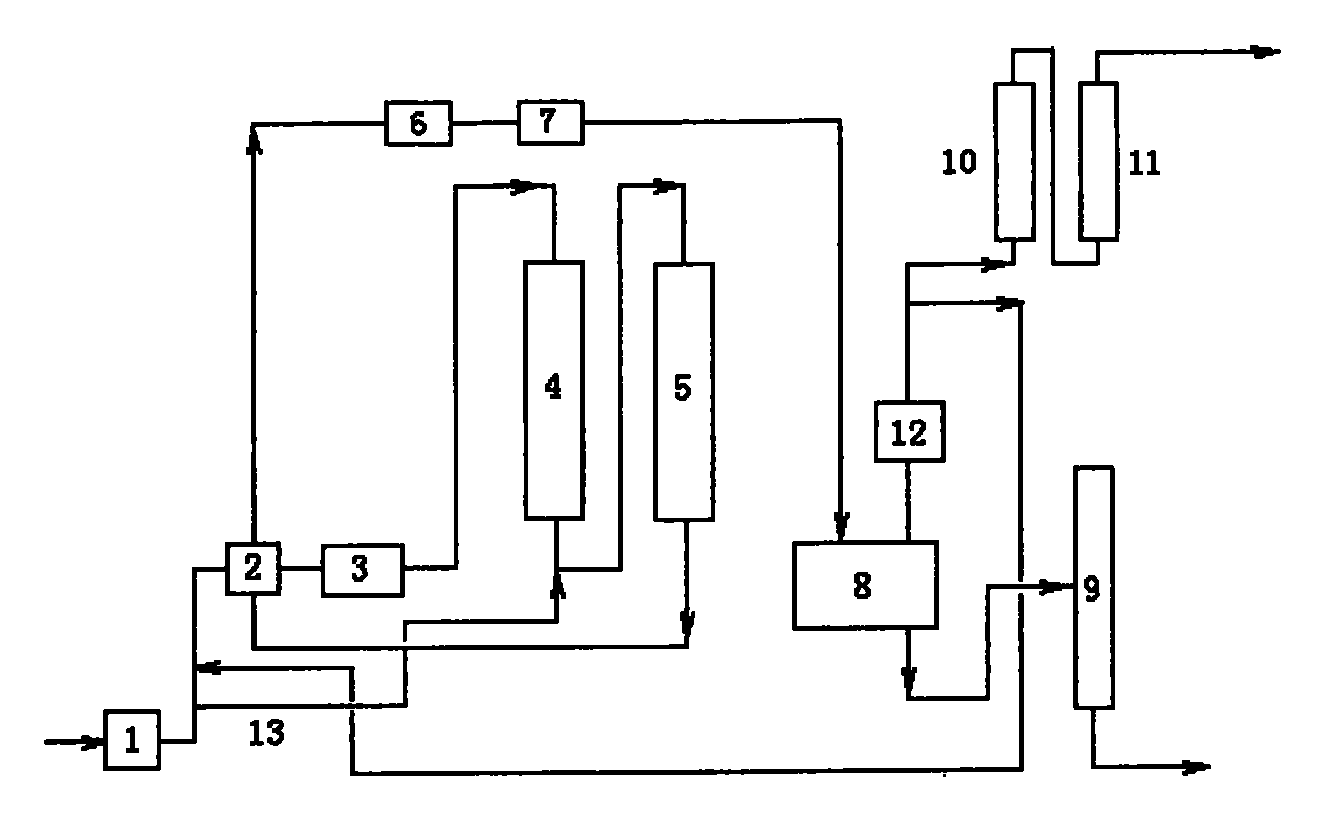

Under-stream method of catalytic reforming device

A reformer and catalyst technology, applied in the petroleum industry, hydrotreating process, processing hydrocarbon oil, etc., can solve the problems of long start-up period, low hydrogen production rate, long time, etc., saving start-up time and high desulfurization rate , the effect of mitigating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Raw material oil: straight-run gasoline, distillation range 60-180°C, sulfur content 300μg / g, arsenic content 10PPb.

[0025]The upper layer of the hydrogen production reactor is filled with RAS-1 adsorbent (product of Changling Oil Refinery) and T-302 adsorbent (product of Nanjing Chemical Industry Company), the filling ratio of the two adsorbents is 1:2 (by weight); the lower layer is filled with 3944 Catalyst (catalyst factory product of Fushun Petrochemical Company), the loading ratio of adsorbent and catalyst is 2: 1 (weight). The pre-hydrogenation reactor is filled with 481-3 catalyst (product of Wenzhou Huahua Group Company).

[0026] Nitrogen is fed into the pre-hydrogenation system and the pressure is raised to 0.5MPa, the pre-hydrogenation reactor is cut off, the temperature of the hydrogen production reactor is raised to 400°C, and naphtha is introduced to produce hydrogen. The operating conditions of the hydrogen production reactor are: space velocity 10h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com