Insulation of stator coil realized by shrinkage hose

A stator coil and hose technology, applied in the direction of coils, insulators, insulated conductors, etc., can solve problems such as motor failure, abrasive wear, cracks in stator coil insulation, etc., to achieve excellent performance and avoid wrinkles and cavities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the accompanying drawings, only the most basic components and components for understanding the present invention are shown. Obviously, the method and equipment of the present invention can be realized in various ways, or made by those of ordinary skill in the art accordingly. Various modification schemes are proposed, however, all the above-mentioned ways and schemes do not deviate from the principles and teachings of the present invention.

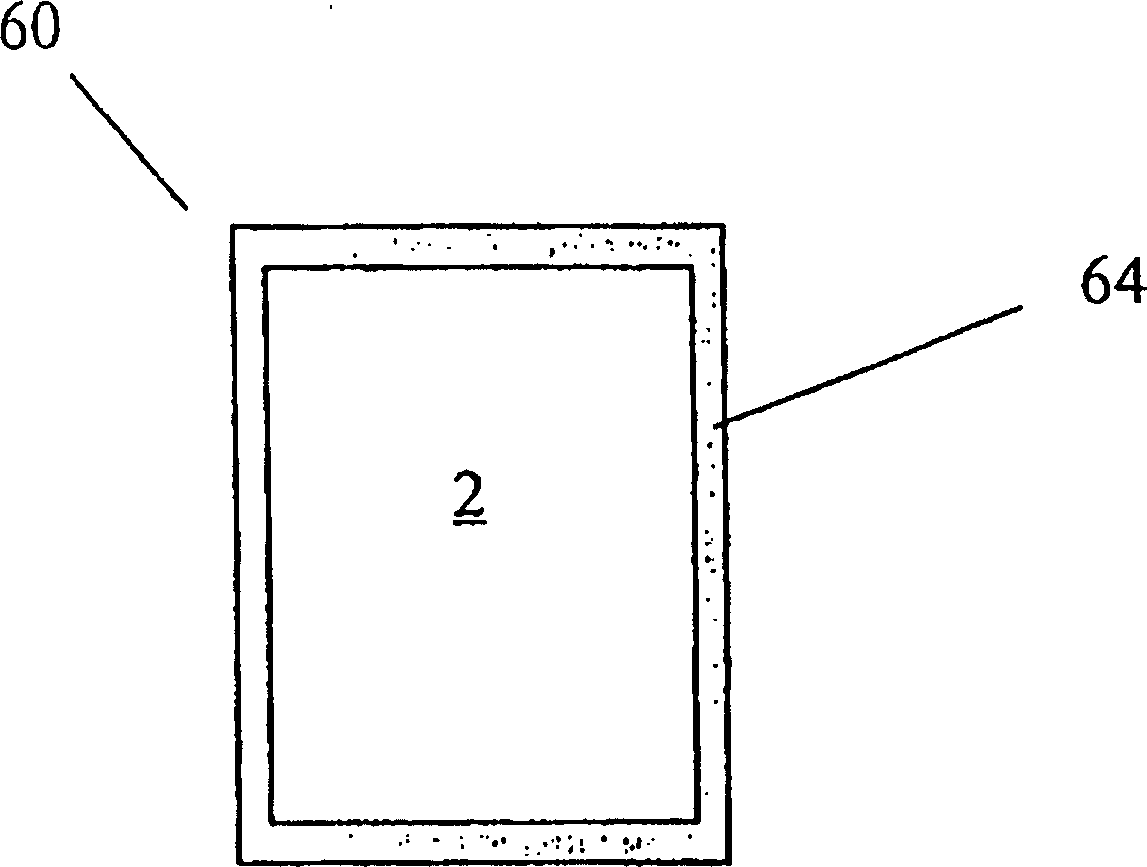

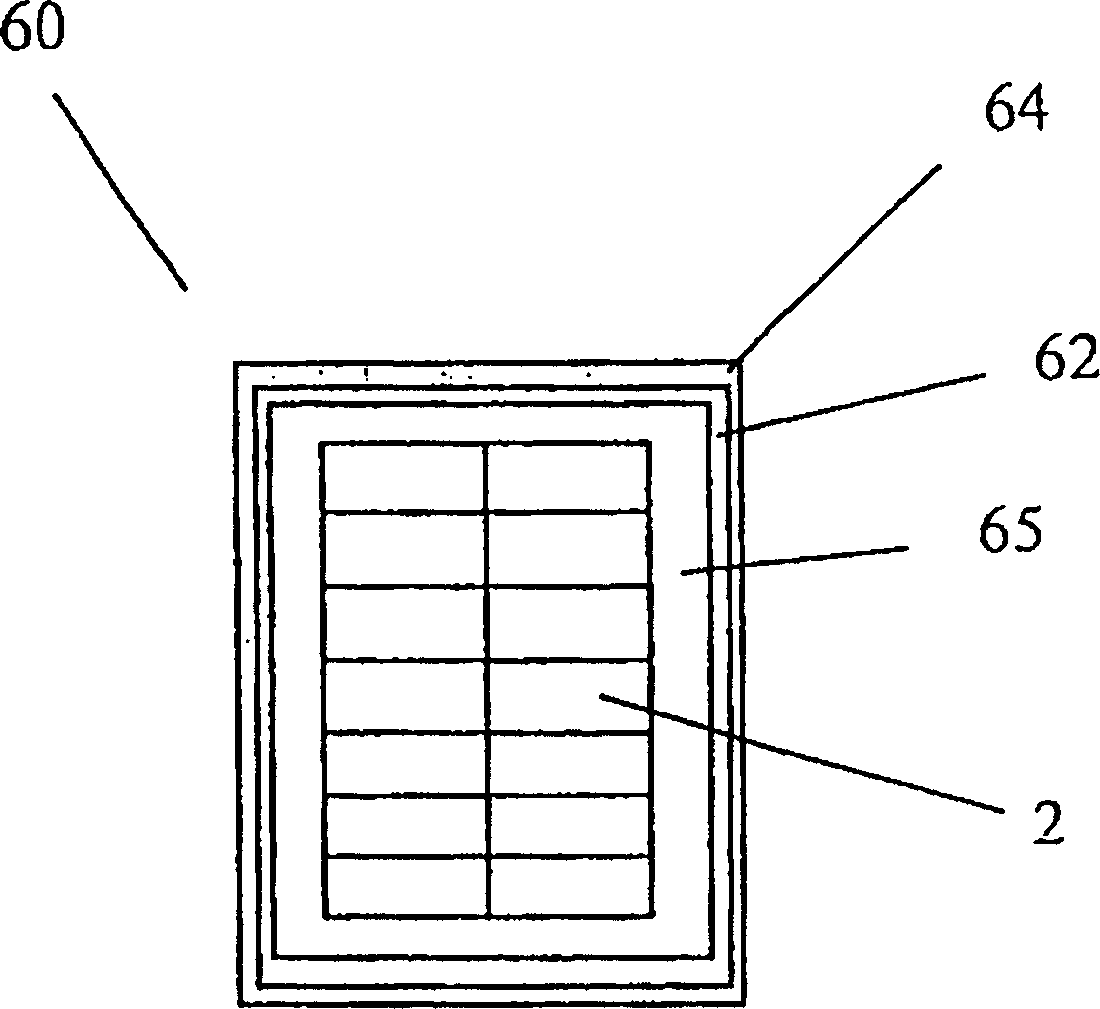

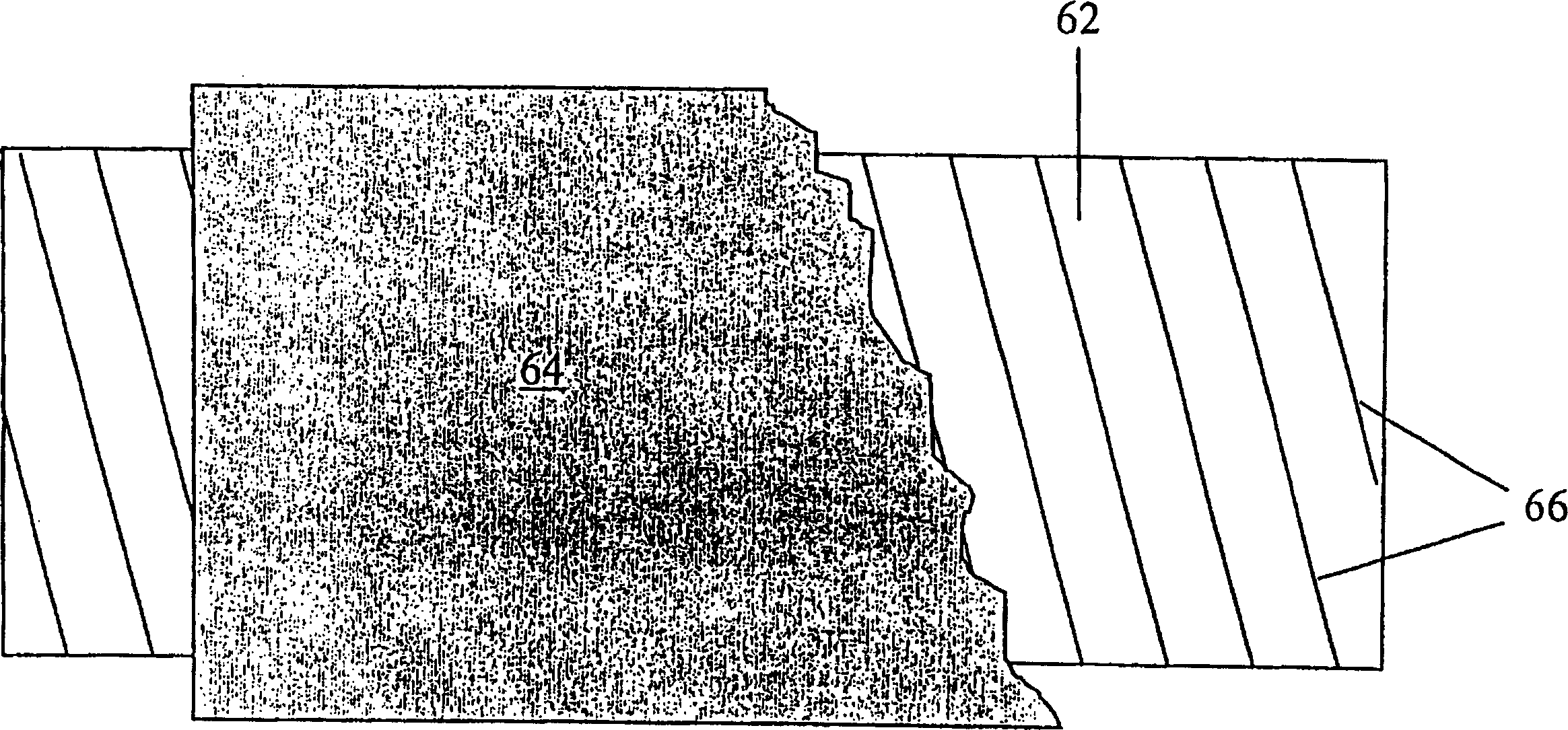

[0032] Figure 1a is a sectional view of an insulated stator coil 60 , a rectangular conductor bar 2 surrounded by a shrink tube 64 . The wire rod itself is generally made up of a number of individual insulated conductors bundled together, in a coiled wire rod a portion of the individual conductors are twisted together, while in an uncoiled wire rod the individual conductors are not twisted, but laid parallel to each other, in the present invention, it is also possible to use a wire rod made of a single conductor with a circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com