Electrolytic capacitor

A technology for electrolytic capacitors and capacitors, applied in the direction of electrolytic capacitors, capacitors, capacitor parts, etc., can solve the problem of not playing a restraining role, and achieve the effect of preventing reduction and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

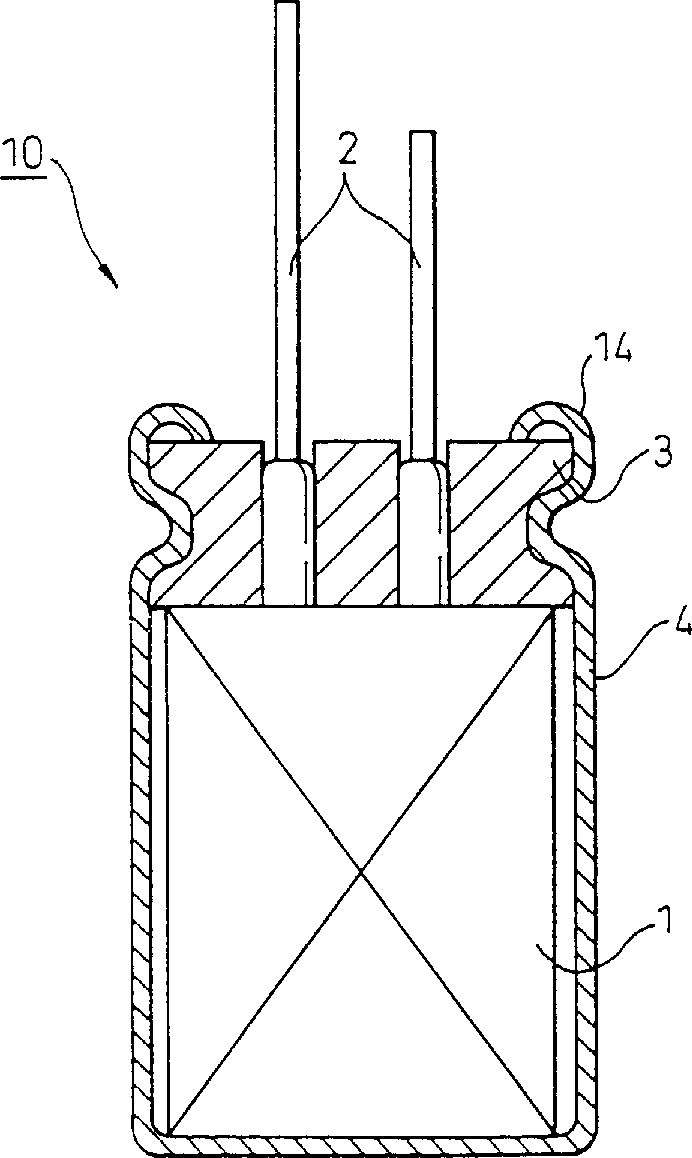

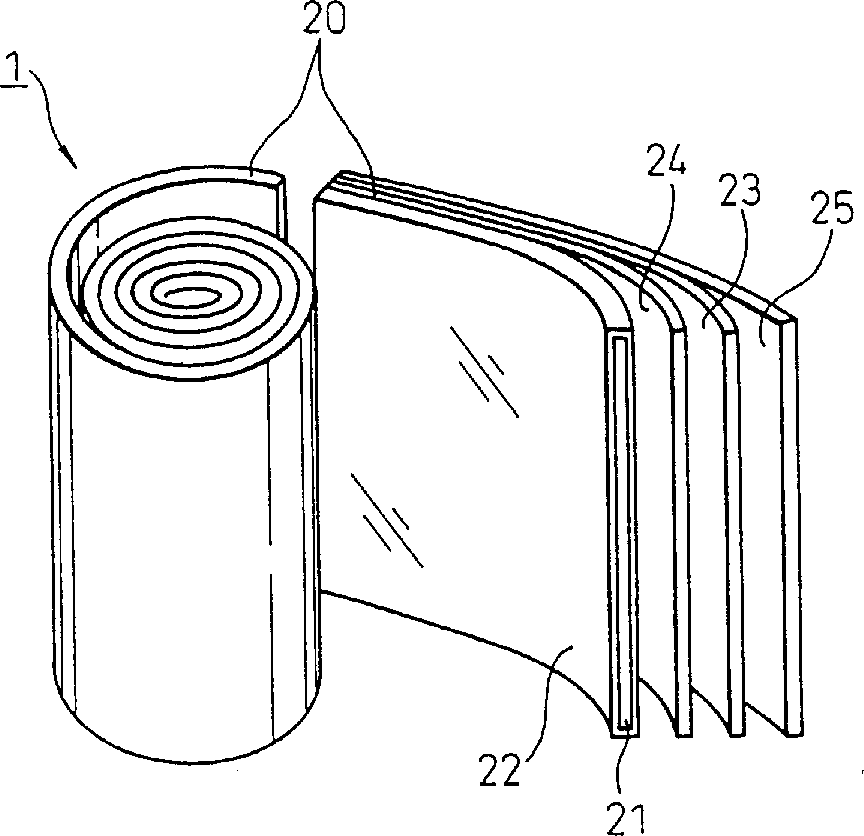

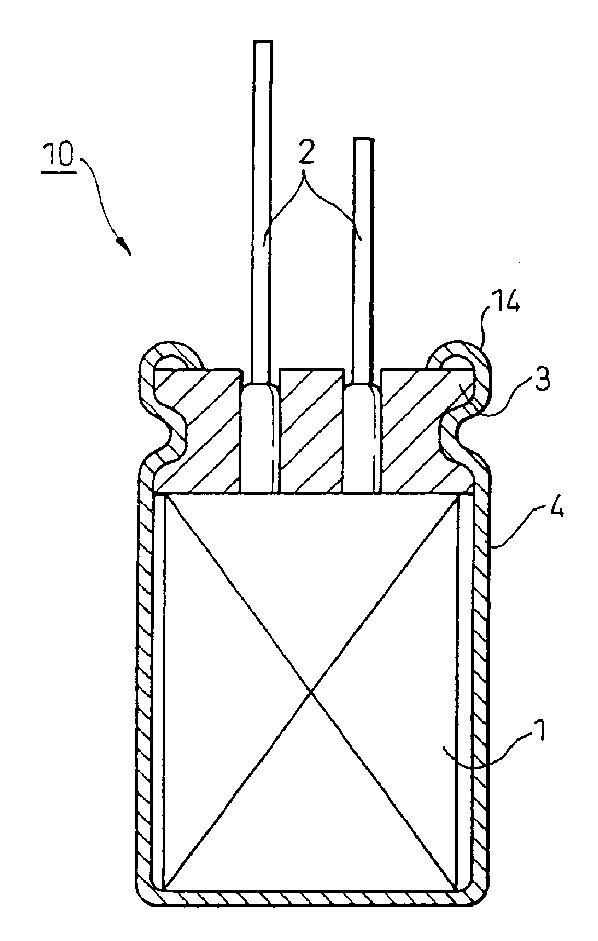

[0062] An aluminum electrolytic capacitor with a coiled structure was prepared according to the following steps.

[0063] First, the aluminum foil is electrochemically corroded, and then anodized to form an anodized film on the entire surface of the aluminum foil, and then connected to a wire joint that leads out the electrode to obtain an aluminum anode electrode. The other aluminum foil is also electrochemically etched, and a lead terminal of an extraction electrode is connected to the foil to form an aluminum cathode foil. Next, a capacitor element was prepared by inserting a separator between the anode electrode and the cathode electrode, followed by crimping. The release paper used here is a paper prepared by using Manila hemp as a raw material. Its cation content is as low as 489ppm due to the washing steps employed in the papermaking process. Then use the electrolytic solution described below to impregnate the capacitor element, and place it in a closed-end aluminum s...

example 2 and 3

[0070] In these two examples, except that the cation content in the release paper used was adjusted to 280ppm (example 2) or 120ppm (example 3), the same process as example 1 was repeated, and the results shown in Table 1 below were obtained. Comparative Examples 1 to 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com