Technology and device for reducing water content in sodium bicarbonate by using filter aid

A filter aid, alkaline water technology, applied in separation methods, chemical instruments and methods, alkali metal carbonates to change crystal water content, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

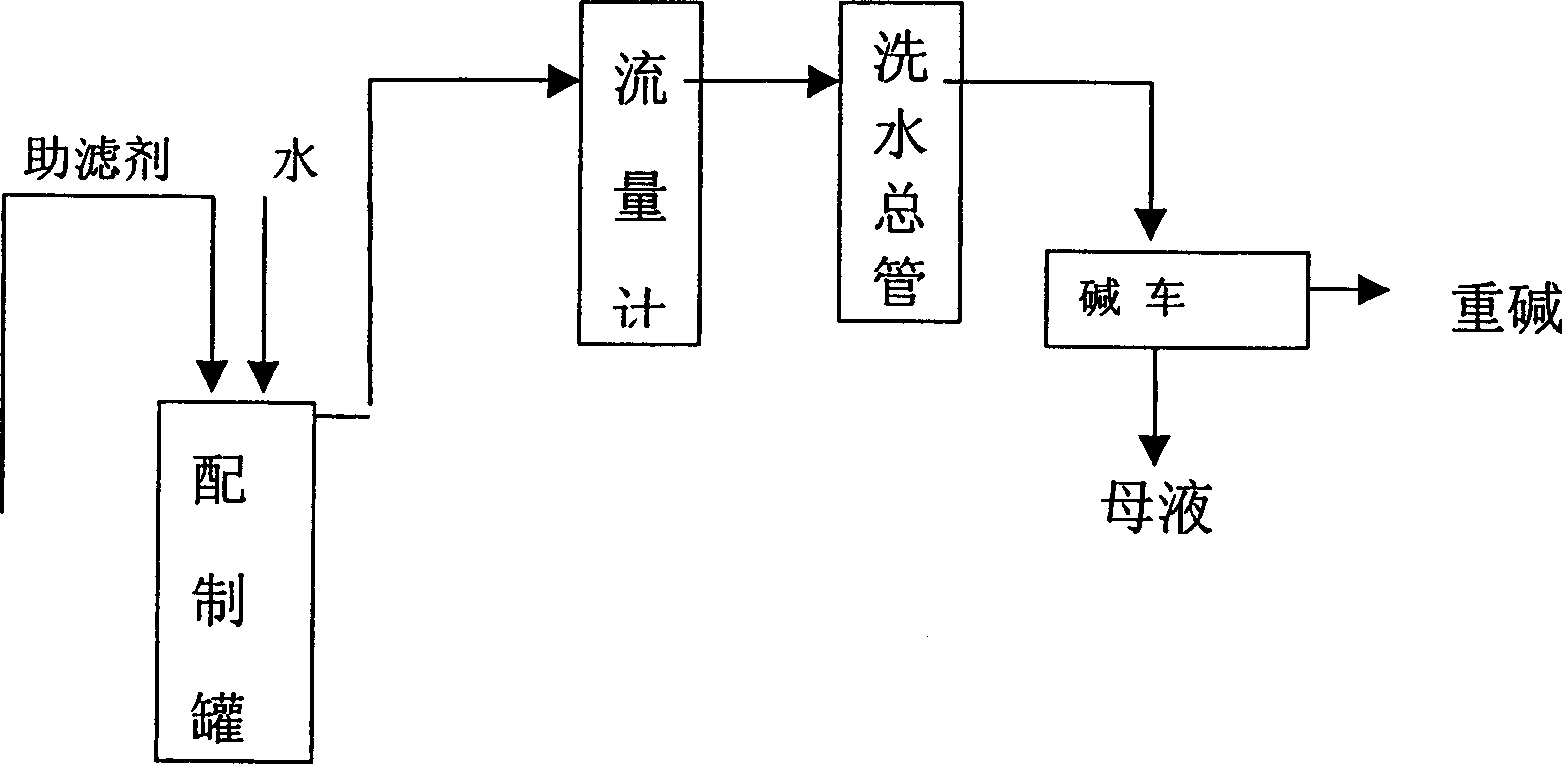

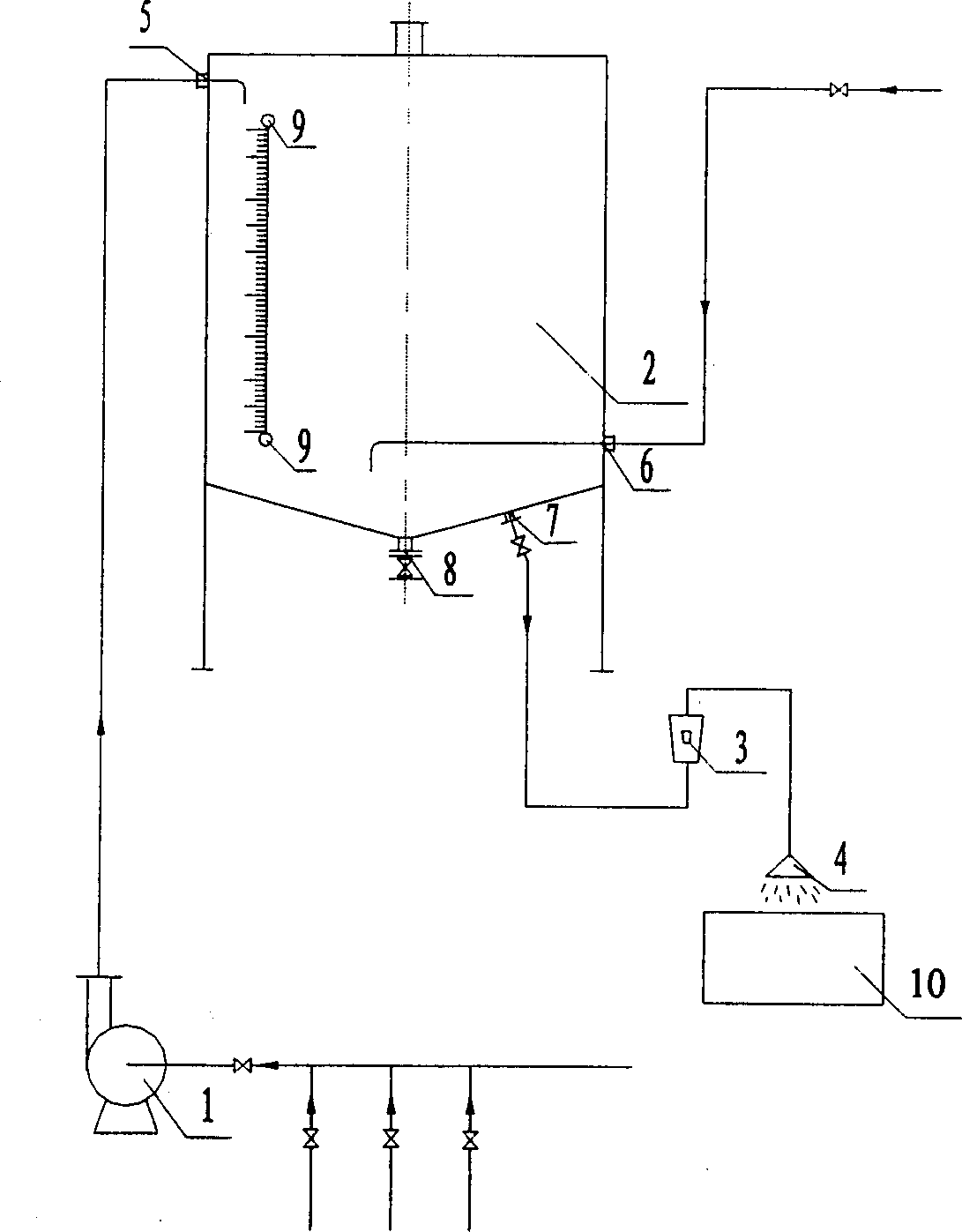

Method used

Image

Examples

Embodiment 1

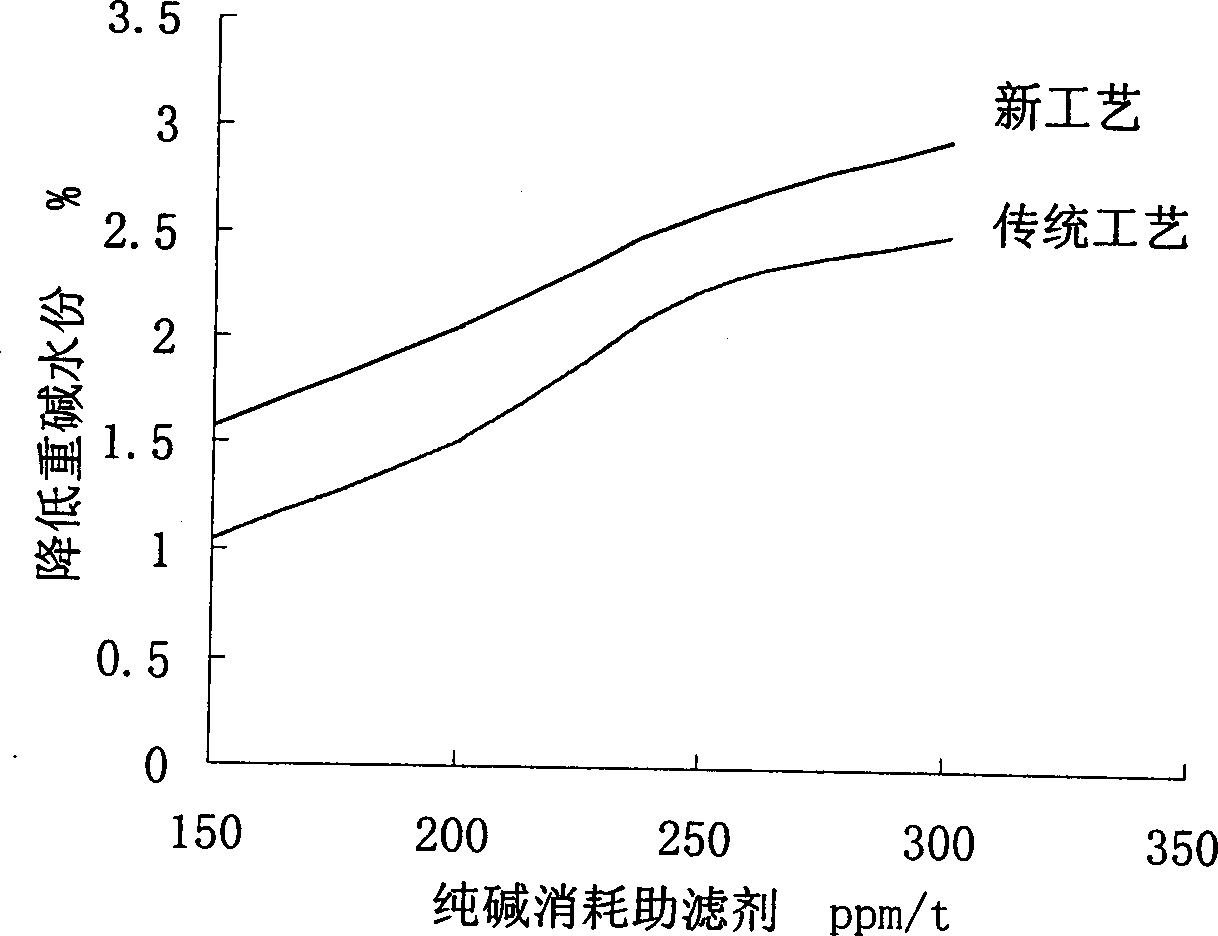

[0026] The stock solution of filter aid is directly added into the alkali discharge tank after being measured by a flow meter, and the dosage of filter aid is 150ppm per ton of soda ash.

[0027] The filter aid used in this test is provided by Tianjin Ruiding Industry and Trade Development Co., Ltd. Its main components are low molecular weight esters, which are colorless or light yellow transparent liquid with a density of 1.000~1.100g / cm 3 , the pH value is 6-8.

[0028] Moisture reduction

[0029] Note: This table lists representative data.

Embodiment 2

[0031] The filter aid stock solution is pumped into the filter aid tank, and water is added to the filter aid tank at the same time to prepare a filter aid dilution solution with a weight percentage of 90%. After being measured by a flow meter, it is sprayed into the alkali outlet tank , The weight of filter aid is 150ppm per ton of soda ash.

[0032] The filter aid selected is the same as in Example 1.

[0033] Moisture reduction

[0034] Note: This table lists representative data.

Embodiment 3

[0036] The filter aid stock solution is pumped into the filter aid tank, and at the same time, water is added to the filter aid tank to prepare a filter aid dilution solution with a weight percentage of 80%. After being measured by a flow meter, it is sprayed into the alkali outlet tank , The dosage of filter aid is 150ppm per ton of soda ash.

[0037] The filter aid selected is the same as in Example 1.

[0038] Moisture reduction

[0039] Note: This table lists representative data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com