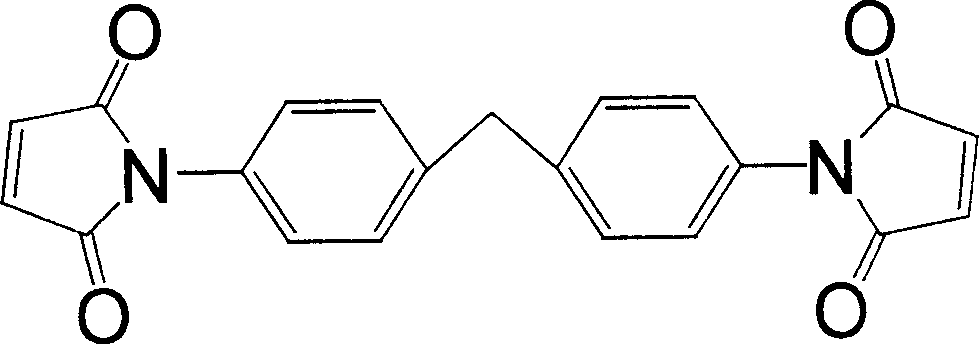

Dimaleimide resin microball, its preparation method and application thereof

A bismaleimide resin and maleimide resin technology, applied in the field of liquid chromatography packing, can solve the problems of poor heat resistance, poor solvent resistance, insufficient rigidity, etc., and achieve easy cleaning and high mechanical strength , Overcome the effect of poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

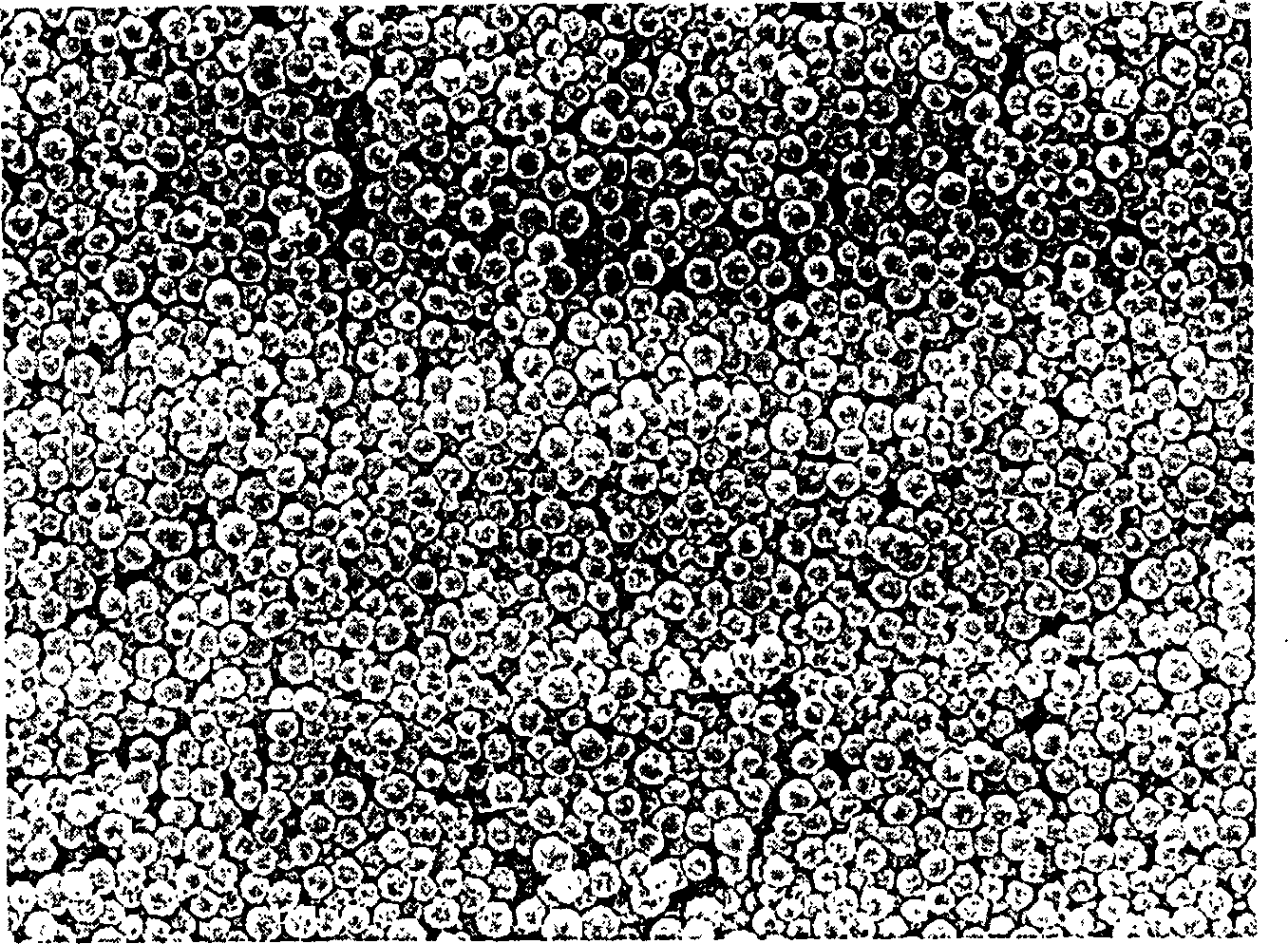

[0015] 50 grams of bismaleimide prepolymer, 50 grams of allyl bisphenol A, and 20 grams of polyetherimide were heated and stirred at 150°C for vacuum degassing and mixing; then the resulting mixture was mixed Decompress and pour into a preheated mold; then cure the mixture placed in the mold at 160°C for 3 hours, then at 185°C for 3 hours, and finally at 200°C for 3 hours; after curing Add 400-500 grams of chloroform to the obtained hardened product, dissolve and wash the polyetherimide contained in the hardened product with the assistance of ultrasonic vibration, wash repeatedly for 3 times, settle, and finally obtain a double horse of 5-7 microns 97 grams of imide resin microspheres.

Embodiment 2

[0017] 57 grams of bismaleimide prepolymer, 43 grams of allyl bisphenol A, and 30 grams of polyester imide were heated and compacted at 170°C for vacuum degassing and mixing; then the resulting mixture was mixed Decompress and pour into a preheated mold; then cure the mixture placed in the mold at 160°C for 3 hours, then at 175°C for 3 hours, and finally at 200°C for 3 hours; after curing Add 500 to 700 grams of N,N'-dimethylacetamide to the obtained hardened product, and dissolve and wash the polyesterimide contained in the hardened product with the assistance of mechanical ball milling, wash repeatedly 3 times, settle, Finally, 96 grams of bismaleimide resin microspheres of 3 to 7 microns were obtained.

Embodiment 3

[0019] Mix 57 grams of bismaleimide prepolymer, 43 grams of allyl bisphenol A, and 40 grams of polyethersulfone in a small screw extruder at 250°C; then pour the mixture into a preheated In a good mold; then cure the mixture placed in the mold at 160°C for 3 hours, then at 180°C for 3 hours, and finally at 200°C for 3 hours; add the cured product obtained after curing to 450-500 gram of N-methylpyrrolidone, and dissolve and wash the polyethersulfone contained in the hardened product with the aid of stirring, wash repeatedly 3 times, settle, and finally obtain bismaleimide resin microspheres of 2 to 6 microns 96 grams. Example 4:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com