Spontaneous intake type internal combustion engine for vehicles

A naturally aspirated, internal combustion engine technology, applied in the direction of internal combustion piston engines, combustion engines, electrical control, etc., can solve the problems of increased cost and weight of internal combustion engines, increased number of parts, improved fuel consumption rate, etc., to increase net indication output, Effect of reducing frictional power loss and improving net fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

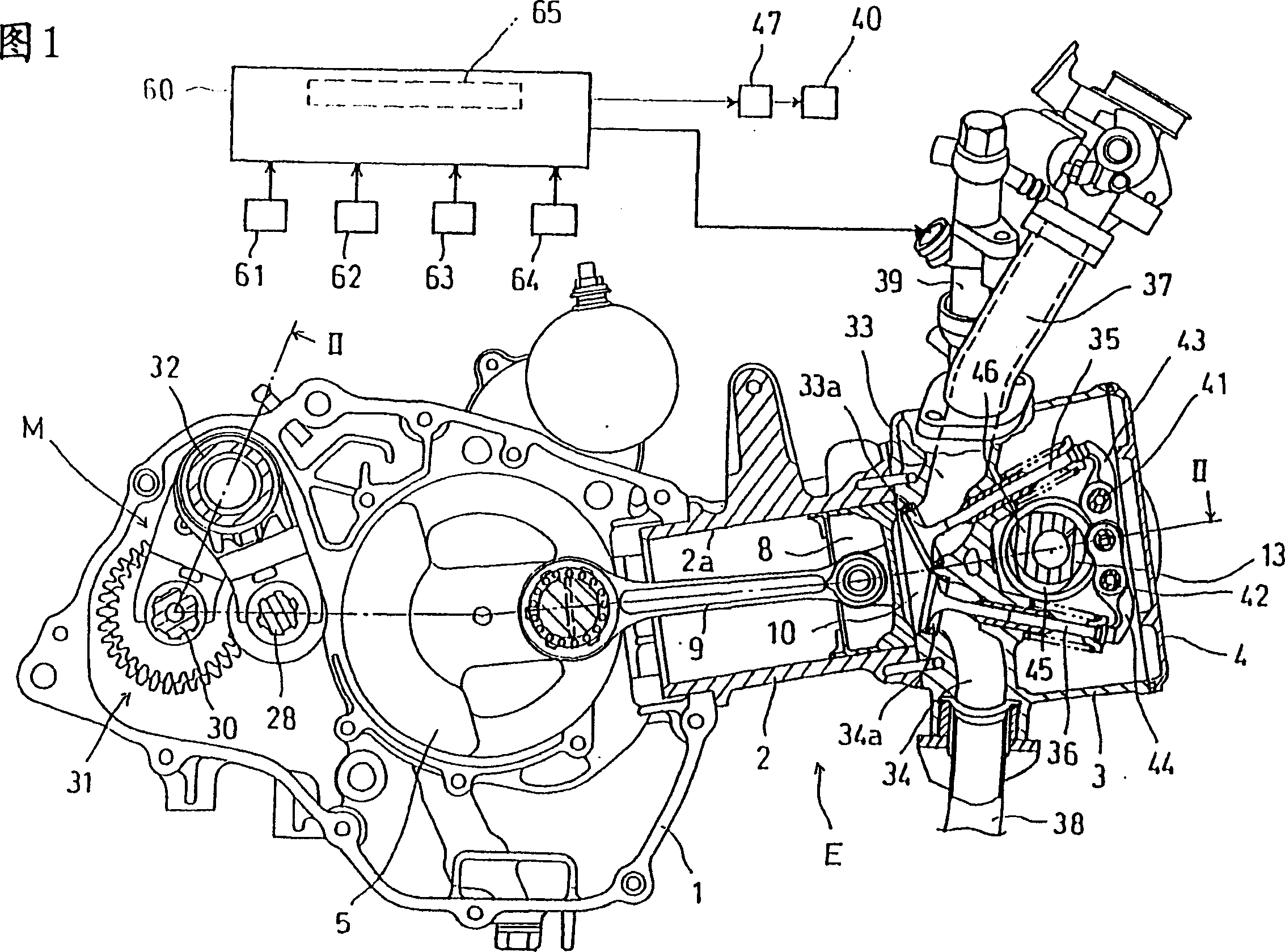

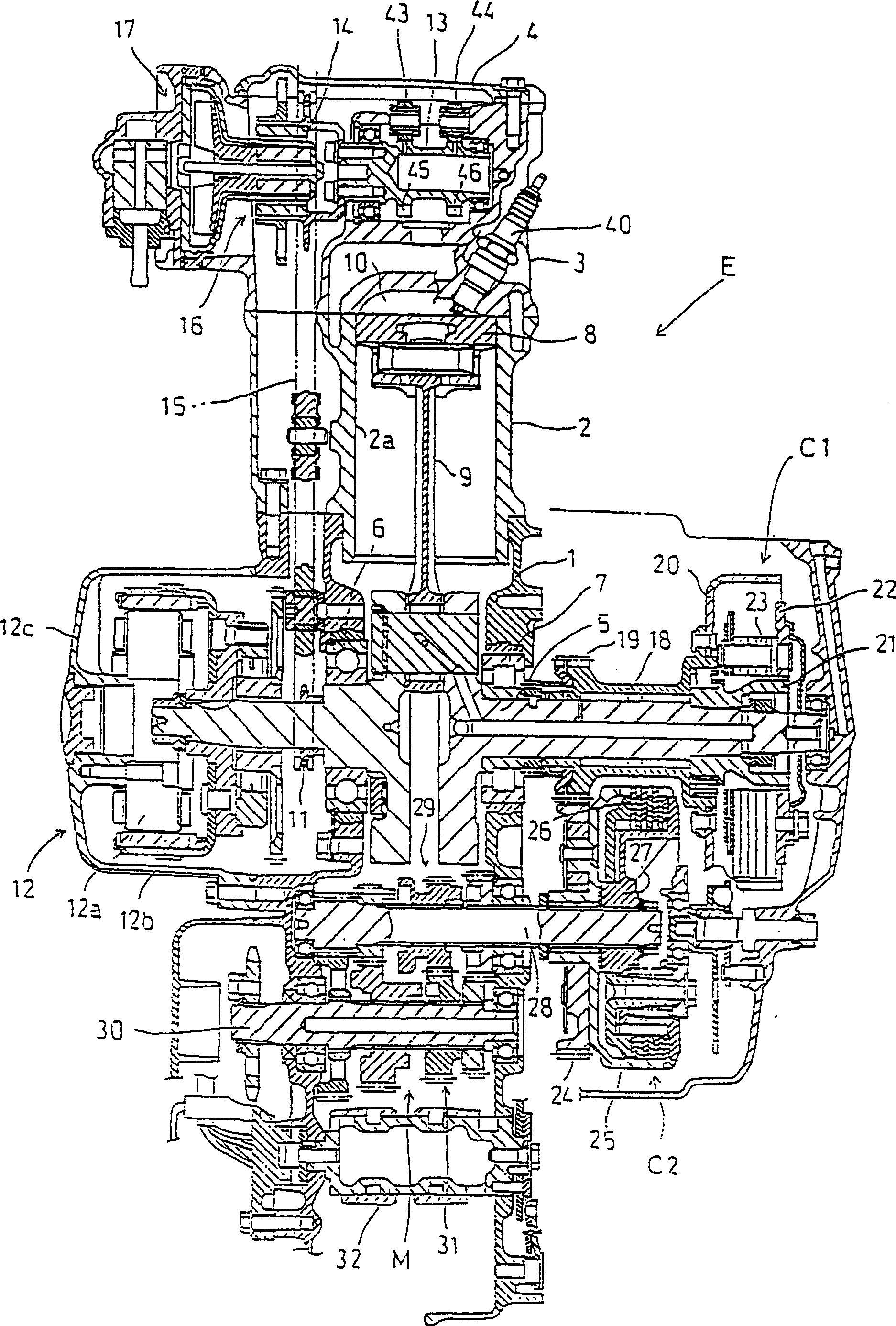

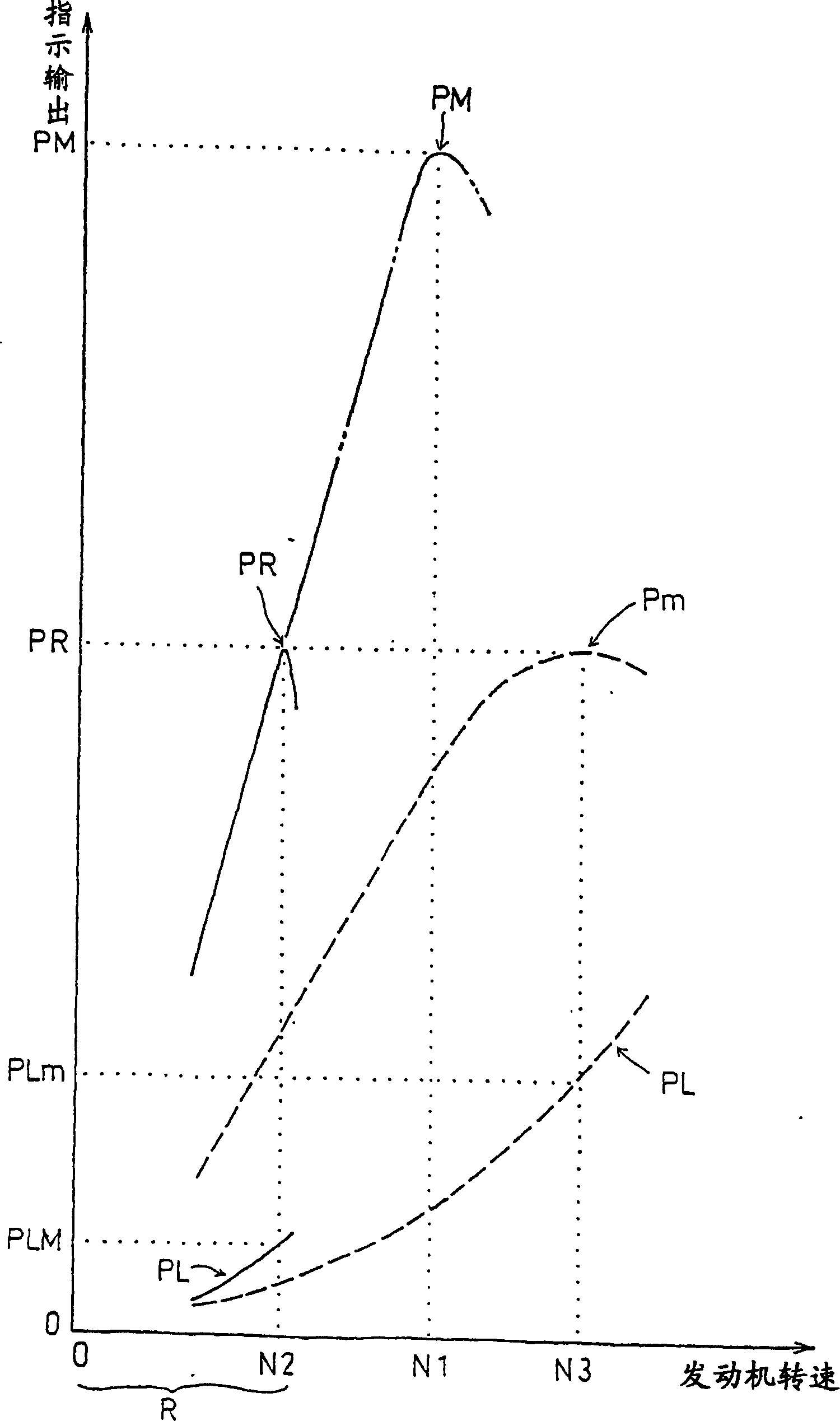

[0016] Below, refer to Figure 1 to image 3 An example of the present invention will be described.

[0017] The naturally aspirated internal combustion engine E to which the present invention is applied is a naturally aspirated reciprocating internal combustion engine of an overhead camshaft type water-cooled single-cylinder 4-stroke mounted on a motorcycle, which is the same as that described later with a transmission clutch C2 and a manual transmission M. The transmissions together form the power unit. In this specification, "front, rear, left, and right" means "front, rear, left, and right" based on the body of the motorcycle.

[0018] Referring to Figure 1 and figure 2 , The internal combustion engine E has a crankcase 1 that is divided left and right, and a cylinder 2, a cylinder head 3, and a cylinder head cover 4 are sequentially assembled and integrated into an engine body. The crankshaft 5 of the internal combustion engine E is rotatably supported on the crankcase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com