Domestic garbage continuous incinerator

A domestic garbage and incinerator technology, applied in the direction of incinerator, combustion method, combustion type, etc., to achieve the effect of ensuring combustion quality and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

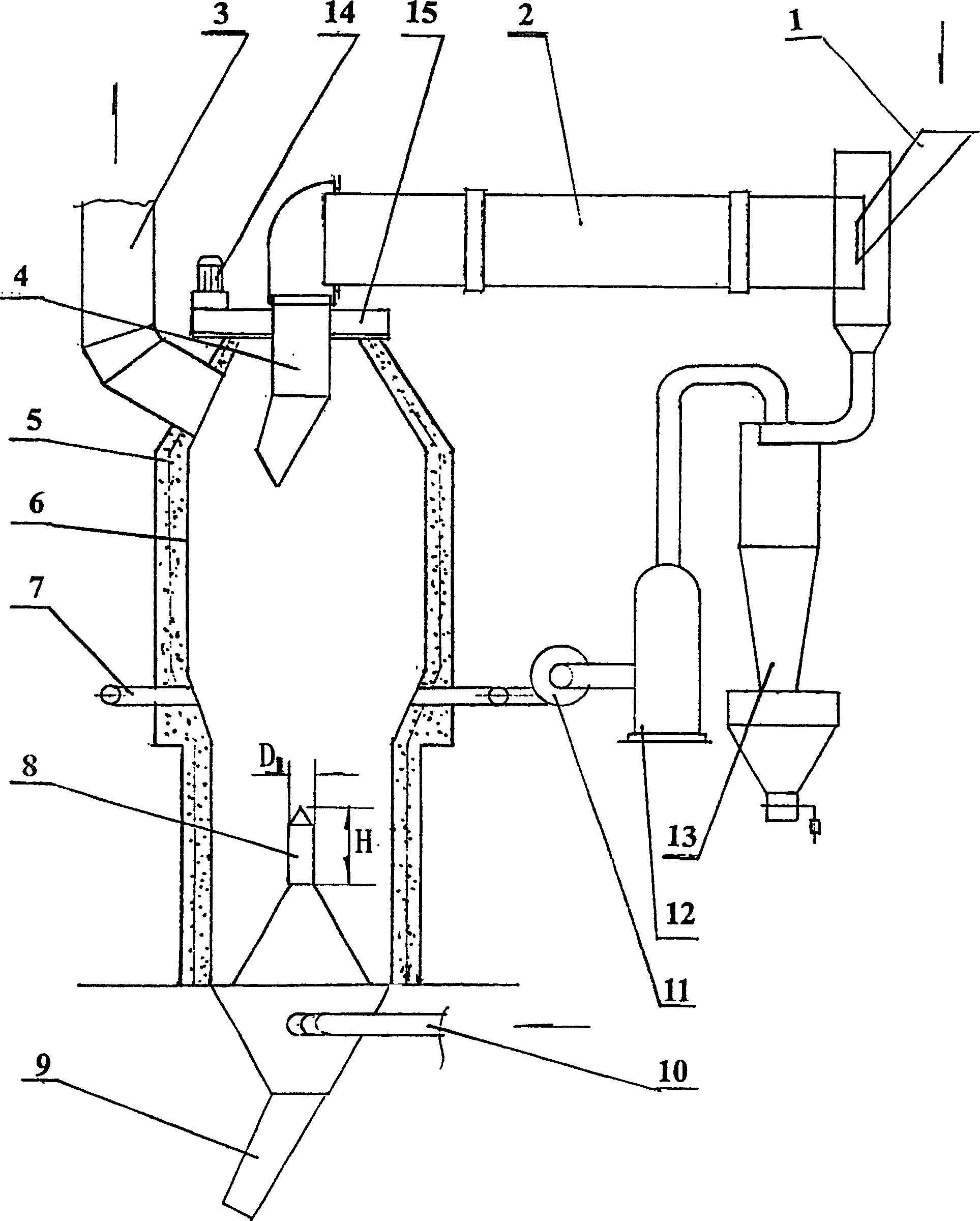

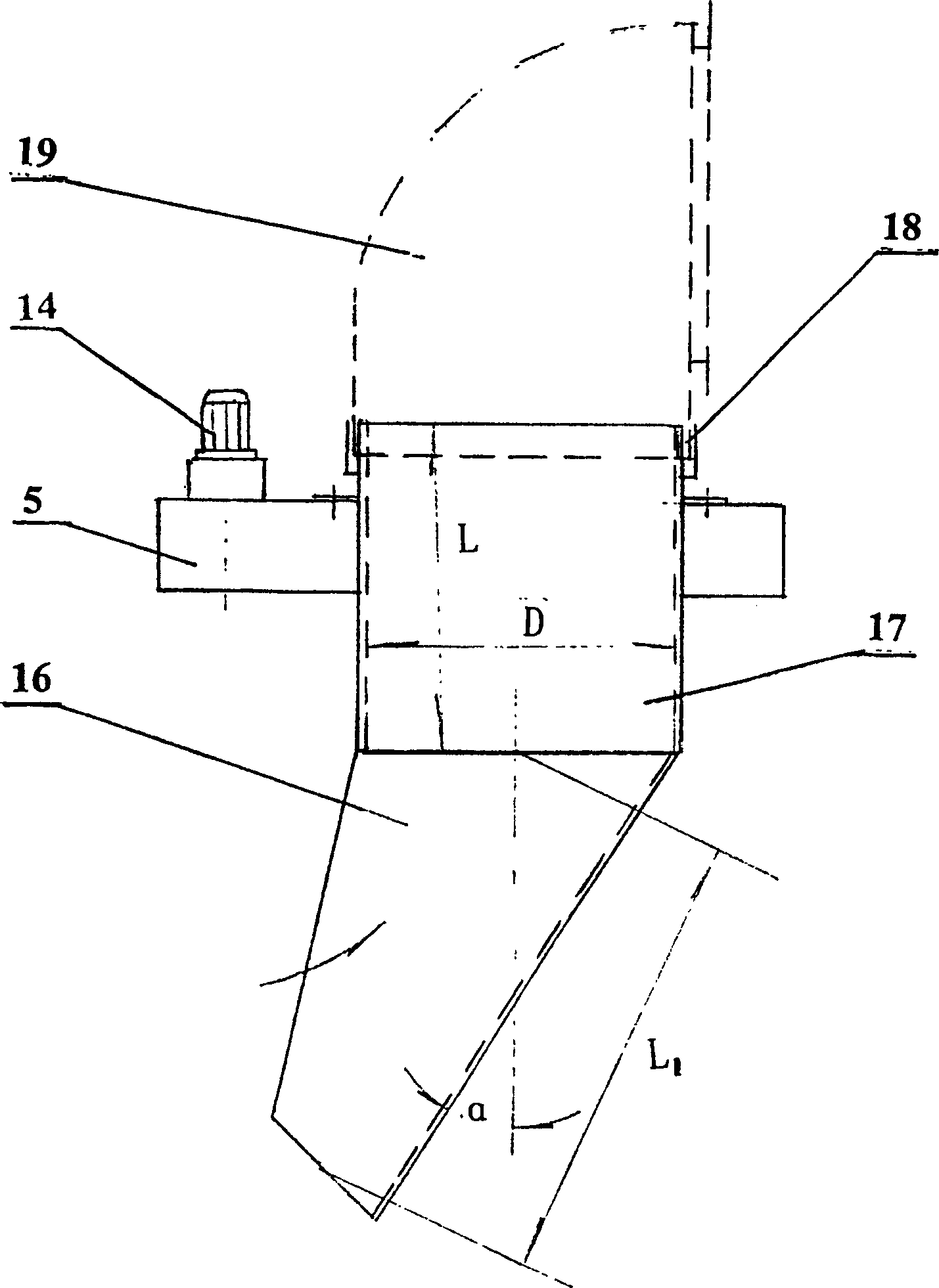

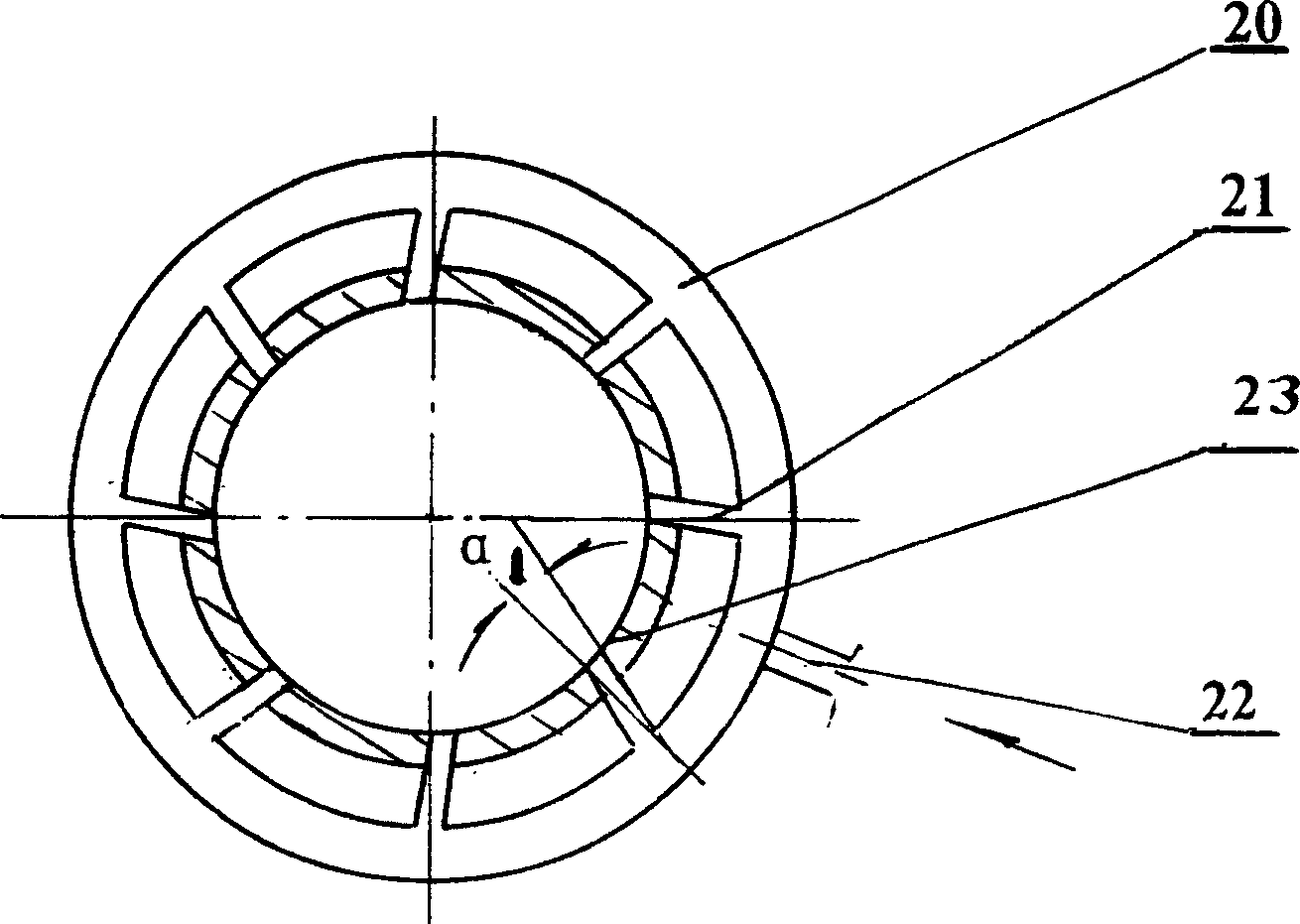

[0015] As shown in each figure, it is a continuous incinerator for domestic waste. It includes a rotary drying and heating system 2, a rotary material distribution system 4, a furnace body 5, an air induction system, a high temperature resistant fan 11, an oxygen enrichment device 12 and a water vapor separator 13. The upper part of the furnace body 5 is provided with a chimney 3 , and the lower part is provided with a slag outlet pipe 9 and an air inlet pipe 10 . The rotary drying and burning system 2 is set on the top of the furnace body 5, one end of which is equipped with a feed hopper 1, and this end also passes through the water vapor separator 13, the oxygen enrichment device 12, the high temperature resistant fan 11 and the annular air inlet pipe device in sequence 7 connected to each other. The rotary distribution system 4 is installed on the top of the furnace body 5, the middle part is a distribution pipe 17, the top of the distribution pipe is connected with a sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com